Water-saving purifier

A water purifier and pure water technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of water resource waste, RO membrane clogging, increased maintenance and use cost and other issues, to achieve the effect of saving water, improving cost and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

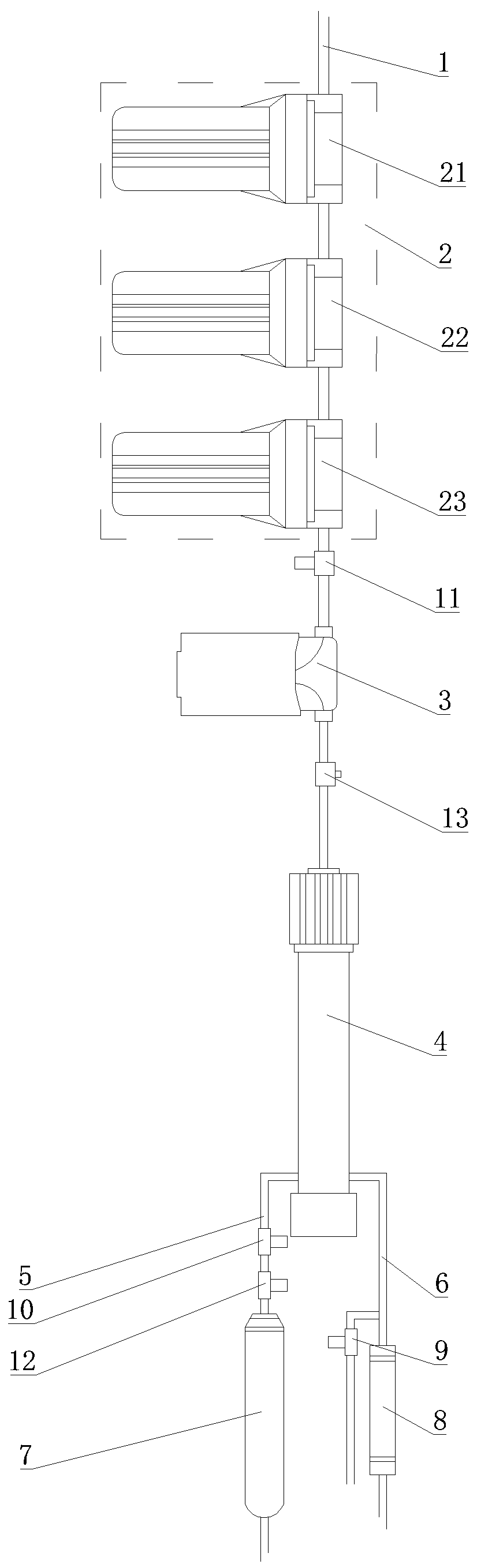

[0018] Embodiment one: as attached figure 1 As shown, a water-saving water purifier includes a first filter device 2 connected to the water pipeline 1, and the first filter device 2 includes a primary PP cotton filter 21 connected to the water pipeline 1 in sequence, Two-stage granular activated carbon filter 22 and three-stage compressed activated carbon filter 23, the water outlet end of the three-stage compressed activated carbon filter 23 of the first filter device 2 is connected with a water pump 3, and the water outlet end of the water pump 3 is provided with RO. Osmosis filtration device 4, described RO reverse osmosis filtration device 4 is provided with pure water outlet pipe 5 and waste water outlet pipe 6, and described pure water outlet pipe 5 is provided with rear activated carbon filter 7, and described waste water outlet pipe 6 is provided with A waste water proportioner 8 is provided, and the waste water proportioner 8 is connected in parallel with a flushing s...

Embodiment 2

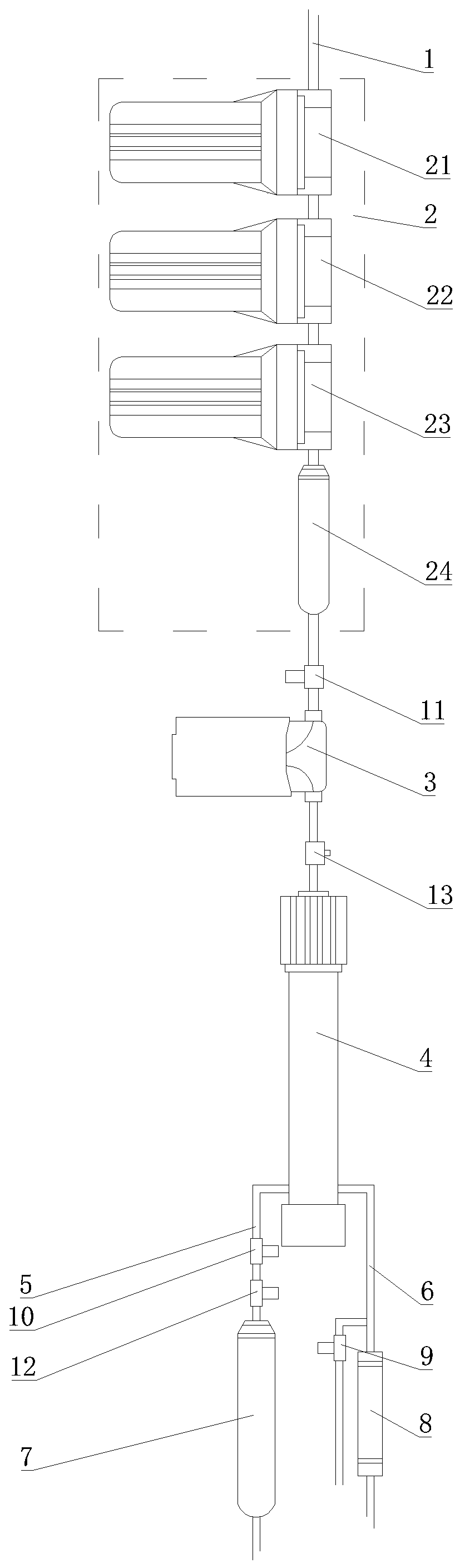

[0033] Embodiment two: as attached figure 2 As shown, in this embodiment, the first filter device 2 includes a four-stage ultrafiltration membrane filter 24, and the water inlet end of the four-stage ultrafiltration membrane filter 24 is connected with the three-stage compressed activated carbon 23 filter , the water outlet end of the four-stage ultrafiltration membrane filter 24 is connected with the water pump 3 . The remaining parts in this embodiment are the same as in Embodiment 1.

[0034] The ultrafiltration membrane can filter particles, bacteria and viruses in water, which can greatly reduce the number of impurities entering the RO membrane, thereby prolonging the service life of the RO membrane more effectively, which can be extended to more than 90% of the life of the traditional method. Replace the RO membrane The number of times is close to that of the traditional method. Moreover, the manufacturing and use costs of the ultrafiltration membrane itself are relat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap