Thin microcrystalline soft light brick and preparation method

A soft light brick and microcrystalline technology, applied in the chemical field, can solve the problems of thick microcrystalline layer, serious reflection, affecting the decorative effect of the brick body and practicability, and achieve the effect of stable performance and good structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

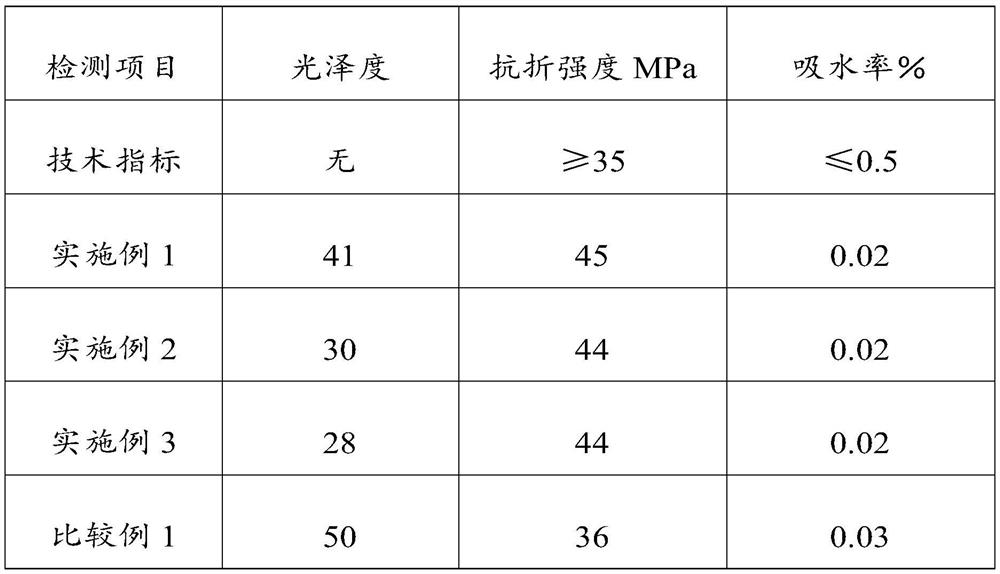

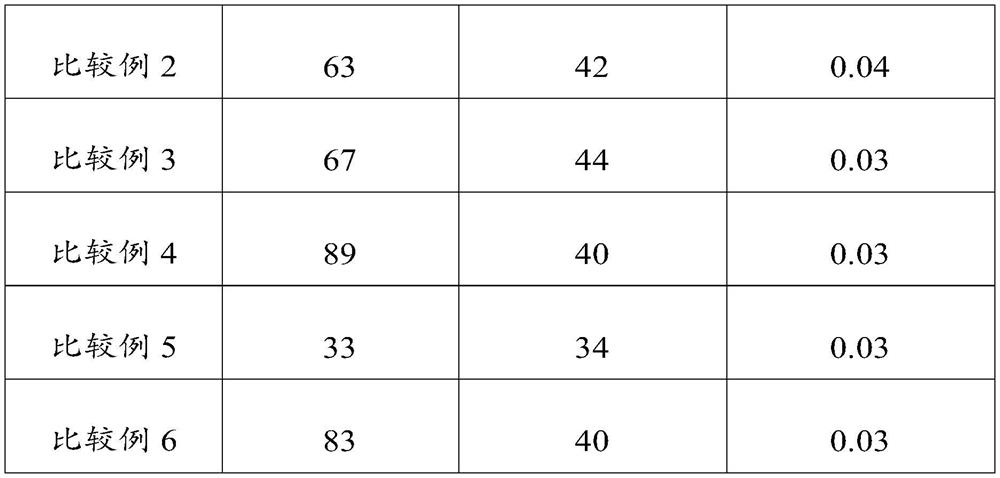

Examples

Embodiment 1

[0040] Follow the steps below to prepare thin microcrystalline soft light tiles:

[0041] A. Green body molding, dry the green body at 500°C for 15 minutes to obtain a shaped green body; the green body includes: feldspar 25%, pyrophyllite 18%, kaolin 25%, white clay 12%, black 8% mud, 10% golden sandstone, 1% sea mud and 1% magnesia mud; in feldspar, 20% of which is greater than or equal to 80 mesh and less than 90 mesh, and 80% of which is greater than or equal to 90 mesh and less than or equal to 100 mesh; 10% of the particle size is greater than or equal to 50 mesh and less than 70 mesh, 90% is greater than or equal to 70 mesh and less than or equal to 80 mesh; in kaolin, 15% of the particle size is greater than or equal to 30 mesh and less than 40 mesh, and 85% is greater than or equal to 40 mesh and less than or equal to 50 mesh %; in the gold sandstone, the particle size is greater than or equal to 100 mesh and less than 110 mesh, accounting for 30%, and greater than or ...

Embodiment 2

[0047] Follow the steps below to prepare thin microcrystalline soft light tiles:

[0048] A. Green body molding, dry the green body at 500°C for 15 minutes to obtain a shaped green body; the green body includes: 30% feldspar, 20% pyrophyllite, 15% kaolin, 10% white clay, black 7% mud, 12% golden sandstone, 3% sea mud and 3% magnesia mud; in feldspar, 20% of which is greater than or equal to 80 mesh and less than 90 mesh, and 80% of which is greater than or equal to 90 mesh and less than or equal to 100 mesh; 10% of the particle size is greater than or equal to 50 mesh and less than 70 mesh, 90% is greater than or equal to 70 mesh and less than or equal to 80 mesh; in kaolin, 15% of the particle size is greater than or equal to 30 mesh and less than 40 mesh, and 85% is greater than or equal to 40 mesh and less than or equal to 50 mesh %; in the gold sandstone, the particle size is greater than or equal to 100 mesh and less than 110 mesh, accounting for 30%, and greater than or ...

Embodiment 3

[0054] Follow the steps below to prepare thin microcrystalline soft light tiles:

[0055] A. Green body molding, dry the green body at 500°C for 15 minutes to obtain a shaped green body; the green body includes: feldspar 28%, pyrophyllite 19%, kaolin 18%, white clay 11%, black 9% of mud, 11% of golden sandstone, 2% of sea mud and 2% of magnesia mud; in feldspar, 20% of particle size is greater than or equal to 80 mesh and less than 90 mesh, and 80% of particle size is greater than or equal to 90 mesh and less than or equal to 100 mesh; in pyrophyllite 10% of the particle size is greater than or equal to 50 mesh and less than 70 mesh, 90% is greater than or equal to 70 mesh and less than or equal to 80 mesh; in kaolin, 15% of the particle size is greater than or equal to 30 mesh and less than 40 mesh, and 85% is greater than or equal to 40 mesh and less than or equal to 50 mesh %; in the gold sandstone, the particle size is greater than or equal to 100 mesh and less than 110 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com