Preparation method of N,N-dibenzyl ethylenediamine diacetate

A technology of dibenzylethylenediamine and acetate is applied in the preparation of carboxylate, carboxylate, amino compound, etc., can solve problems such as high cost, harsh conditions, etc., improve yield, reduce reaction Cost, effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

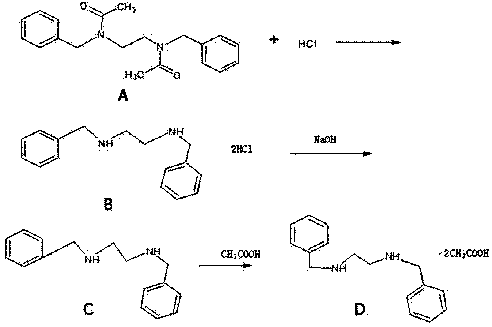

Method used

Image

Examples

Embodiment

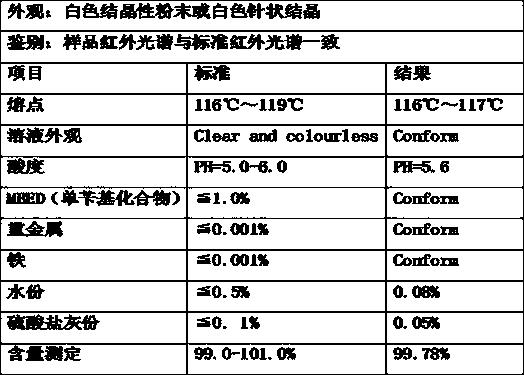

[0030] A kind of preparation method of N,N-dibenzylethylenediamine diacetate, its method step is as follows:

[0031]

[0032] S1. Add 50 parts by weight of diacetyldibenzylethylenediamine material into the three-necked bottle, add 80-120 parts by weight of concentrated hydrochloric acid with a concentration of 30% to 31% into the three-necked bottle, and then slowly heat up the three-necked bottle to 72 ~76°C, react for 5 hours after heating up, then cool the three-neck flask to 0~3°C with cooling water, and then filter to obtain 36.0~37.5 parts by weight of compound B;

[0033] S2. Add 36.0 to 37.5 parts by weight of compound B obtained in step S1 into 200 parts by weight of water to fully dissolve, and add dropwise a sodium hydroxide solution 5.2 to 5.6 with a concentration of 97.5% to 98.5% at a temperature of 10 to 20°C. parts by weight, adjust the pH value to 8-9; after the pH value is adjusted, add 50 parts by weight of toluene for the first extraction and layering t...

Embodiment 1

[0036] A kind of preparation method of N,N-dibenzylethylenediamine diacetate, its method step is as follows:

[0037] S1. Add 50g of diacetyldibenzylethylenediamine material into a 1000ml three-necked bottle, add 100g of concentrated hydrochloric acid with a concentration of 30% to 31% into the three-necked bottle, then slowly heat up the three-necked bottle to 74°C, and react after heating After 5 hours, the temperature of the three-neck flask was lowered to 3°C with cooling water, and then filtered to obtain 37.3 g of compound B;

[0038] S2. Add 37.3 g of compound B obtained in step S1 to 200 g of water to fully dissolve, add dropwise 5.4 g of sodium hydroxide solution with a concentration of 97.5% to 98.5% at a temperature of 15°C, and adjust the pH value to 8.5; After the pH value has been adjusted, add 50g of toluene for the first extraction and layering treatment; after the first extraction and layering treatment are completed, then add 50g of toluene for the second ext...

Embodiment 2

[0043] A kind of preparation method of N,N-dibenzylethylenediamine diacetate, its method step is as follows:

[0044] S1. Add 50g of diacetyldibenzylethylenediamine material into the three-necked flask, add 120g of concentrated hydrochloric acid with a concentration of 30% to 31% into the there-necked flask, then slowly raise the temperature to 76°C in the there-necked flask, and react for 5 hour, then cooled the three-necked flask to 1.5°C with cooling water, and then filtered to obtain 37.3g of compound B;

[0045] S2. Add 37.3 g of compound B obtained in step S1 to 200 g of water to fully dissolve, add dropwise 5.4 g of sodium hydroxide solution with a concentration of 97.5% to 98.5% at a temperature of 20° C., and adjust the pH value to 9; After the pH value has been adjusted, add 50g of toluene for the first extraction and layering treatment; after the first extraction and layering treatment are completed, then add 50g of toluene for the second extraction and layering tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com