High-K dielectric groove lateral double-diffused metal oxide element semiconductor field effect transistor and manufacturing method thereof

A technology of lateral double-diffusion and field effect transistors, applied in the field of lateral double-diffusion metal oxide element semiconductor field effect transistors and its production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

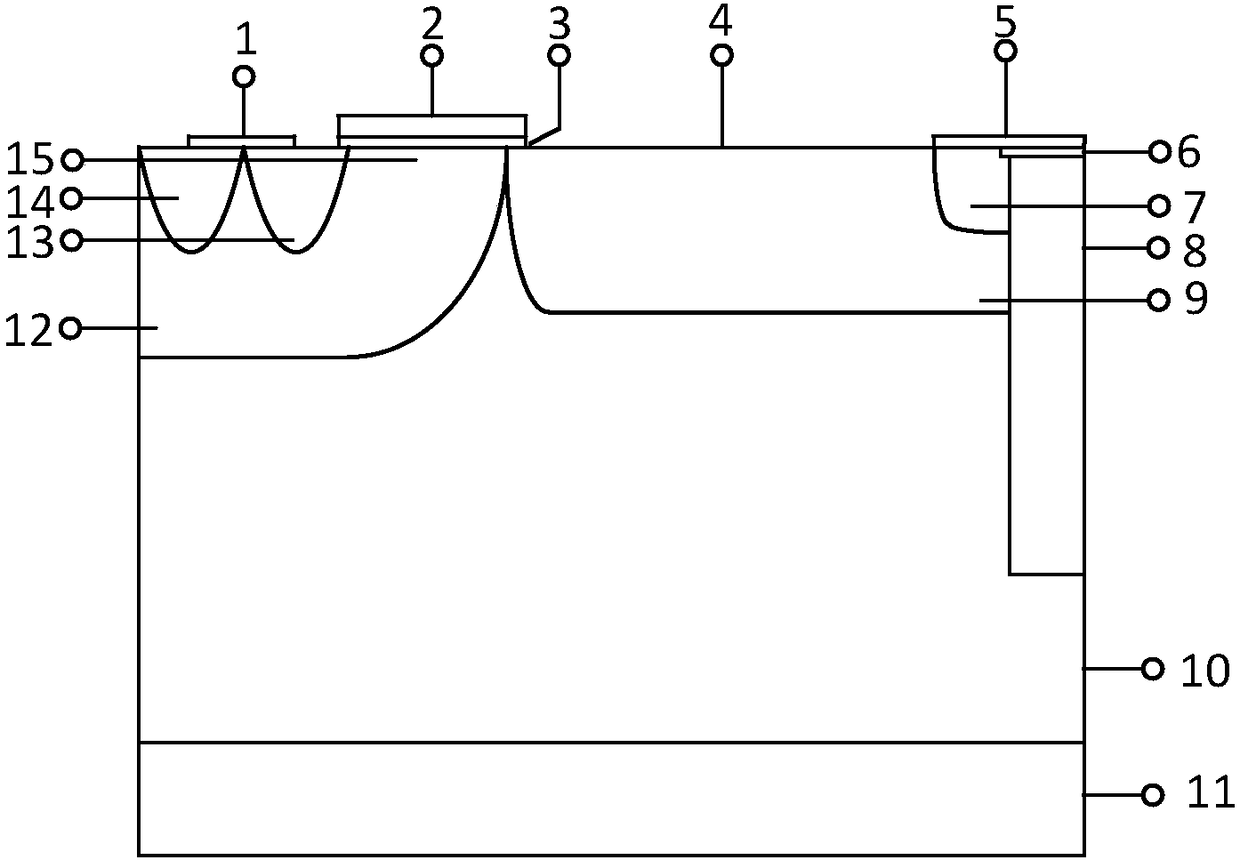

[0043] Such as figure 1 As shown, the high-K dielectric trench lateral double-diffused metal oxide element semiconductor field effect transistor of the present invention includes:

[0044] A substrate 11 of elemental semiconductor material (such as silicon or germanium) (the doping concentration of the substrate is 1×10 13 cm -3 ~1×10 15 cm -3 );

[0045] an epitaxial layer 10 grown on a substrate 11;

[0046] A base region 12 and a drift region 9 formed on the epitaxial layer 10;

[0047] A source region 13 and a channel 15 formed on one side of the base region 12 adjacent to the drift region 9, and a drain region 7 formed on the other side of the drift region 9;

[0048] a channel substrate contact 14 formed outside the source region 13 in the base region;

[0049] The source electrode 1 formed by shorting the contact surface between the source region and the channel substrate;

[0050] A gate insulating layer 3 and a gate electrode 2 formed corresponding to the chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com