A kind of photovoltaic cell assembly and its manufacturing method

A technology of photovoltaic cells and components, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of easy aging and yellowing, high working temperature, temperature rise of transparent tempered glass, etc., to achieve improved working stability, excellent thermal conductivity, The effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

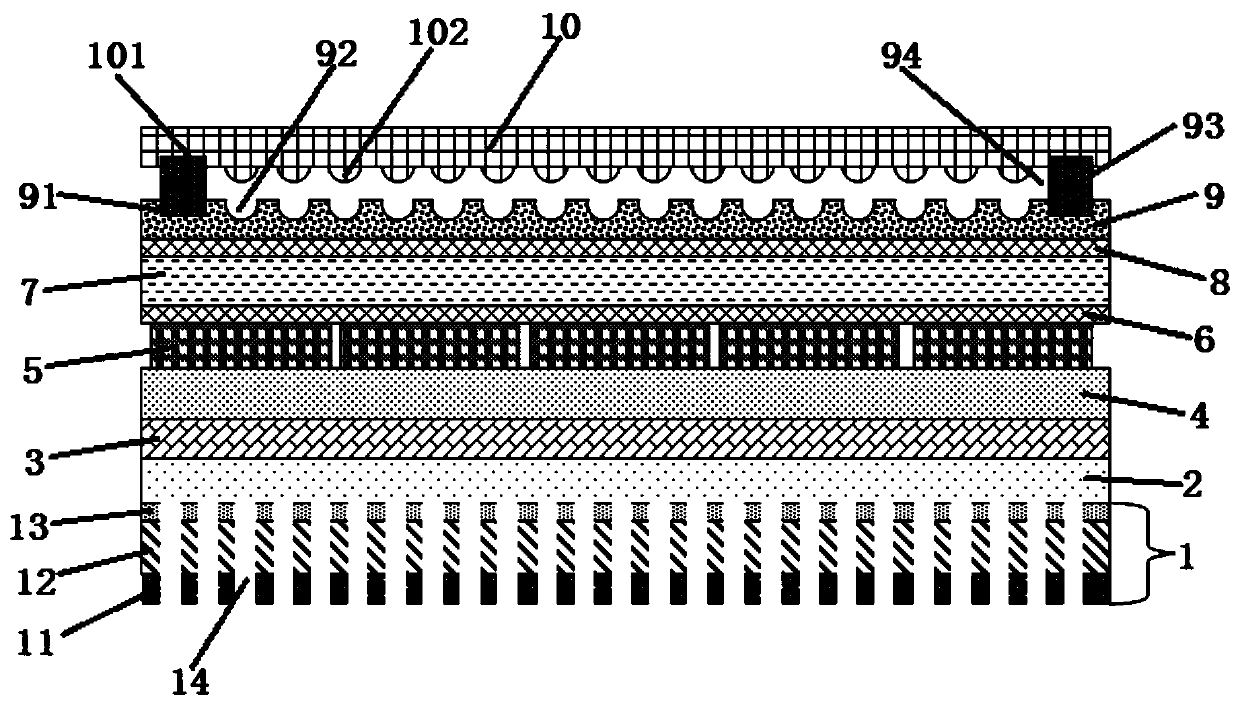

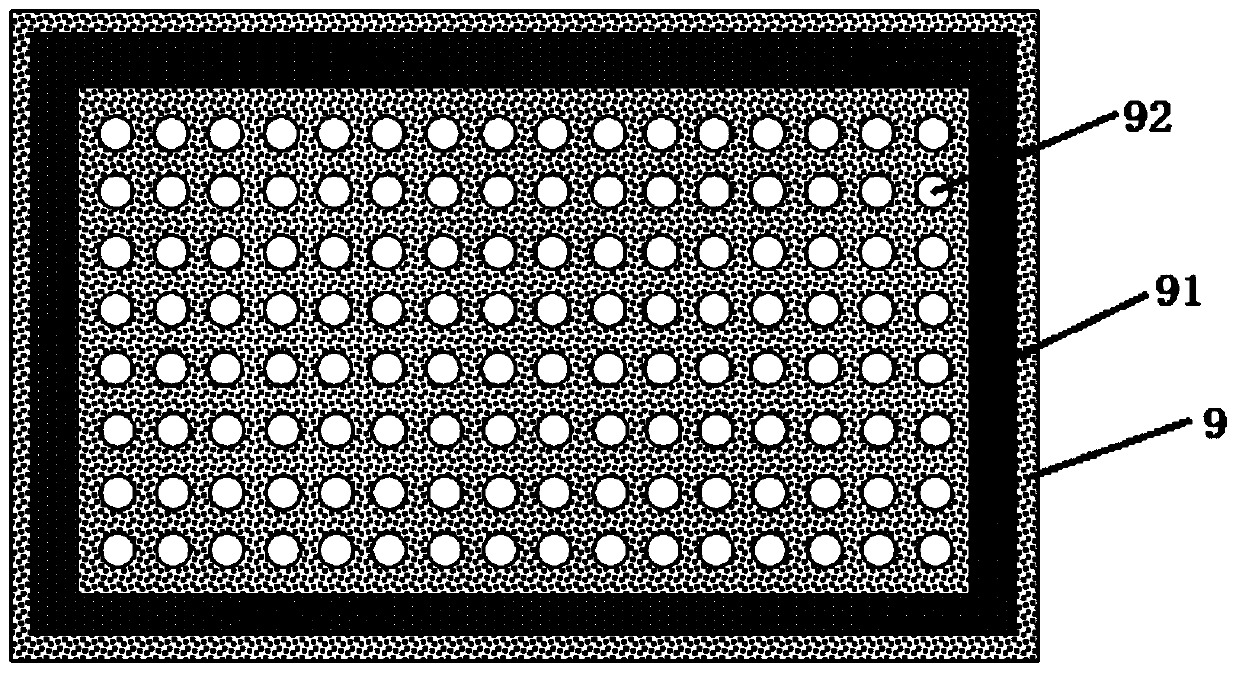

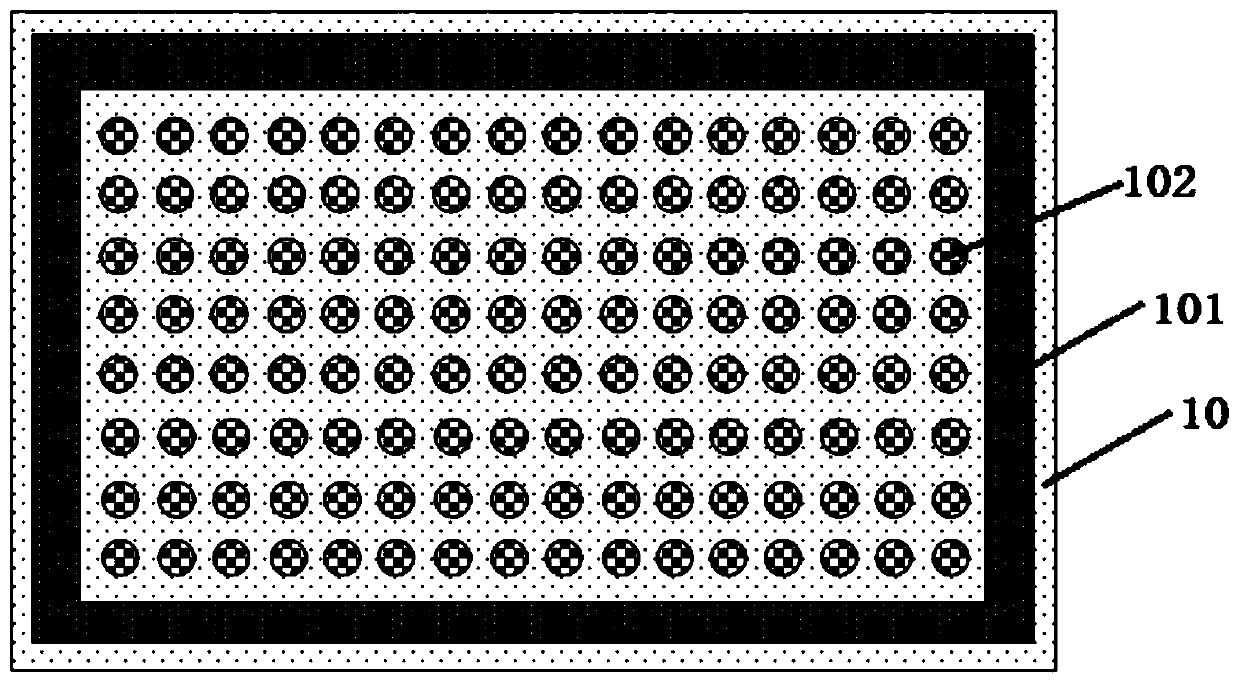

[0026] A method for preparing a photovoltaic cell assembly proposed in a specific embodiment of the present invention comprises the following steps:

[0027] 1) A resin backplane is provided, a plurality of through holes are opened on the resin backplane, and a first thermally conductive packaging adhesive layer is laid on the resin backplane, and the first thermally conductive packaging adhesive layer includes polyolefin and relative to 100 parts by weight of the polyolefin is 5-10 parts by weight of the first heat-conducting nanoparticles;

[0028] 2) laying a second thermally conductive packaging adhesive layer on the first thermally conductive packaging adhesive layer, the second thermally conductive packaging adhesive layer comprising ethylene-vinyl acetate copolymer and 100 weights relative to the ethylene-vinyl acetate copolymer Parts are 10-15 parts by weight of second heat-conducting nanoparticles, the particle diameter of the second heat-conducting nanoparticles is l...

Embodiment 1

[0043] A method for preparing a photovoltaic cell assembly, comprising the following steps:

[0044] 1) A resin backplane is provided, a plurality of through holes are opened on the resin backplane, and a first thermally conductive packaging adhesive layer is laid on the resin backplane, and the first thermally conductive packaging adhesive layer includes polyolefin and relative to 100 parts by weight of the polyolefin is 8 parts by weight of the first heat-conducting nanoparticles;

[0045] 2) laying a second thermally conductive packaging adhesive layer on the first thermally conductive packaging adhesive layer, the second thermally conductive packaging adhesive layer comprising ethylene-vinyl acetate copolymer and 100 weights relative to the ethylene-vinyl acetate copolymer Parts are 12 parts by weight of the second heat-conducting nanoparticles, the particle diameter of the second heat-conducting nanoparticles is larger than the particle diameter of the first heat-conducti...

Embodiment 2

[0053] A method for preparing a photovoltaic cell assembly, comprising the following steps:

[0054] 1) A resin backplane is provided, a plurality of through holes are opened on the resin backplane, and a first thermally conductive packaging adhesive layer is laid on the resin backplane, and the first thermally conductive packaging adhesive layer includes polyolefin and relative to 100 parts by weight of the polyolefin is 10 parts by weight of the first heat-conducting nanoparticles;

[0055] 2) laying a second thermally conductive packaging adhesive layer on the first thermally conductive packaging adhesive layer, the second thermally conductive packaging adhesive layer comprising ethylene-vinyl acetate copolymer and 100 weights relative to the ethylene-vinyl acetate copolymer Parts are 15 parts by weight of the second heat-conducting nanoparticles, the particle diameter of the second heat-conducting nanoparticles is larger than the particle diameter of the first heat-conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com