Preparation method of silicon carbon cathode material

A negative electrode material, silicon carbon technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of uneven material composition, toxicity, and easy pollution of the environment by chemical substances, so as to ensure safety, uniform material dispersion, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

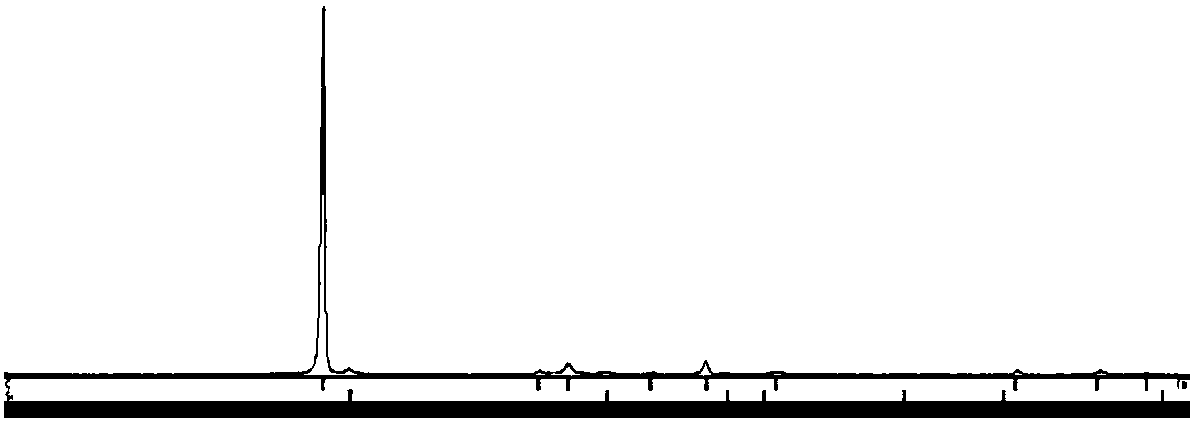

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for preparing a silicon-carbon negative electrode material, which includes the following steps:

[0056] (1) Under the protection of an inert gas, 25% wt of asphalt and 1% wt of polyethylene glycol are put into a mixer for heating and melting, and the heating temperature is 150° C.;

[0057] (2) Add 70%wt graphite and 4% nano-silicon powder to the mixer, and use the mixer to carry out mechanical stirring for 2 hours to obtain a premixed material;

[0058] (3) Put the premixed material into a self-cleaning twin-screw extruder for stirring, extrude and shear the material, fully disperse the silicon powder, and obtain a silicon-carbon precursor. Among them, the self-cleaning twin-screw extruder The screw speed is 200rpm, the heating temperature of the first section is 170°C, the heating temperature of the second section is 120°C, and the heating temperature of the third section is 80°C;

[0059](4) Under the protection of an inert gas, ca...

Embodiment 2

[0063] This embodiment provides a method for preparing a silicon-carbon negative electrode material, which includes the following steps:

[0064] (1) Under the protection of an inert gas, put 20%wt of high-density polyethylene and 0.8%wt of glycerin into a mixer for heating and melting, and the heating temperature is 160°C;

[0065] (2) Add 75%wt graphite and 4.2% nano-silicon powder to the mixer, and use the mixer to carry out mechanical stirring for 2 hours to obtain the premixed material;

[0066] (3) Put the premixed material into a self-cleaning twin-screw extruder for stirring, extrude and shear the material, fully disperse the silicon powder, and obtain a silicon-carbon precursor. Among them, the self-cleaning twin-screw extruder The screw speed is 200rpm, the heating temperature of the first section is 170°C, the heating temperature of the second section is 120°C, and the heating temperature of the third section is 80°C;

[0067] (4) Under the protection of an inert g...

Embodiment 3

[0071] This embodiment provides a method for preparing a silicon-carbon negative electrode material, which includes the following steps:

[0072] (1) Under the protection of an inert gas, 15%wt of asphalt and 1.2%wt of polyethylene glycol are put into a mixer for heating and melting, and the heating temperature is 100°C;

[0073] (2) Add 78.8%wt graphite and 5% nano-silicon powder to the mixer, and use the mixer to mechanically stir for 1 hour to obtain the premixed material;

[0074] (3) Put the premixed material into a self-cleaning twin-screw extruder for stirring, extrude and shear the material, fully disperse the silicon powder, and obtain a silicon-carbon precursor. Among them, the self-cleaning twin-screw extruder The screw speed is 200rpm, the heating temperature of the first section is 150°C, the heating temperature of the second section is 100°C, and the heating temperature of the third section is 50°C;

[0075] (4) Under the protection of an inert gas, carbonize th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com