A Method for Preparing Glass Electrolyte with Effective Control of Water Vapor Removal Rate

A water vapor and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of long reaction time, inability to wait for the expected product, and inability to obtain the ideal glass table solid electrolyte, etc., to slow down the escape speed and slow down The effect of water absorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

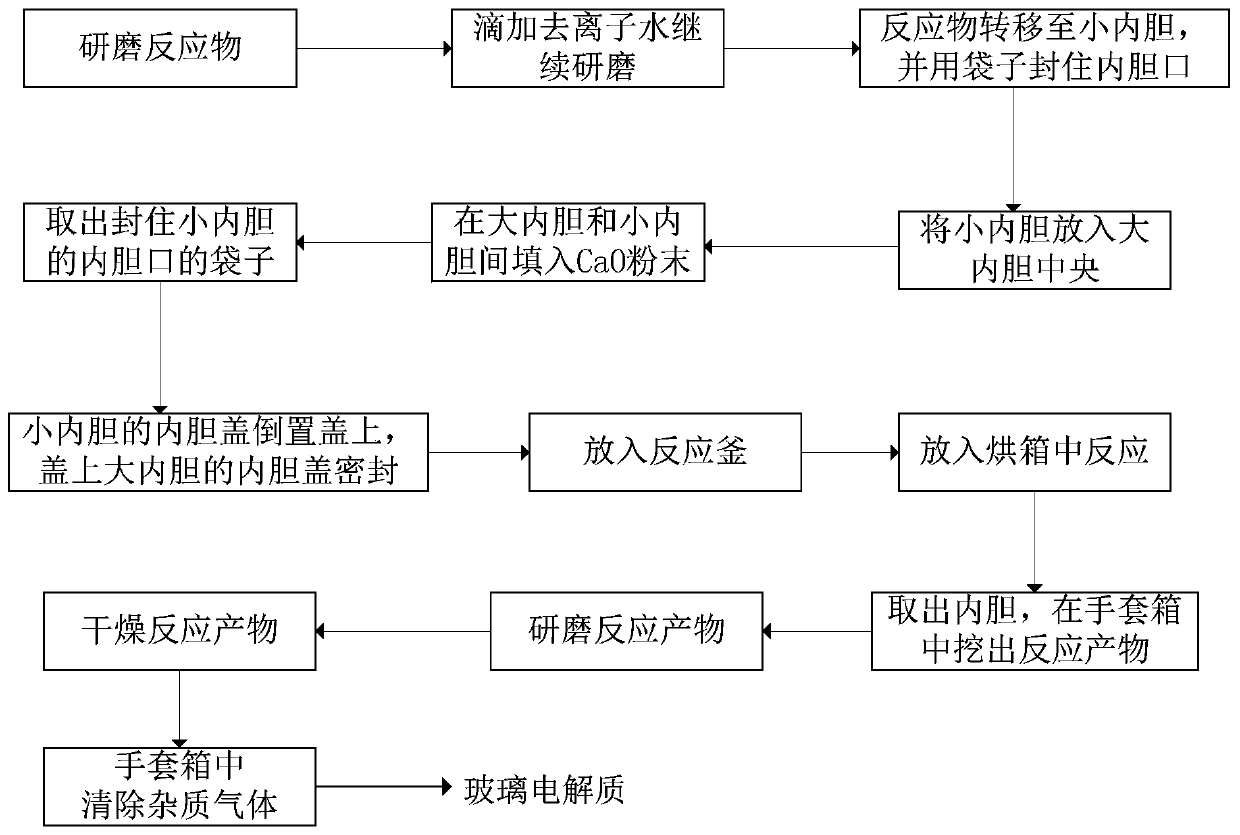

[0051] Please refer to figure 1 , a method for preparing a glass electrolyte capable of effectively controlling water vapor removal rate, comprising the following steps:

[0052] S1. Weigh 2.616g LiCl·H according to the stoichiometric ratio 2 O, 3.634g Li(OH)·H 2 O, grind in an agate mortar for 20 minutes to make it fully mixed without obvious graininess;

[0053] S2. Add 2-3ml deionized water dropwise until it is ground into a paste;

[0054] S3. Use a clean medicine spoon to scrape it into the 25mL high-temperature-resistant PPL liner, take a bag, cut off the seal and put it on the mouth of the 25mL liner;

[0055] S4. Carefully put the 25mL liner of the sleeve into the center of another 50mL high temperature resistant PPL liner;

[0056] S5. Weigh 10g of CaO powder, carefully and slowly transfer it to the space around the 25mL liner and the 50mL liner with a clean and dry medicine spoon, pay attention to evenly fill the surrounding area, so that the 25mL liner is always...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com