A kind of sintering method of NdFeB magnet

A sintering method, NdFeB technology, applied in the manufacture of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of limited effect and high micro-cracks, reduce escape velocity, good magnetic properties, and increase pre-heating. The effect of the sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

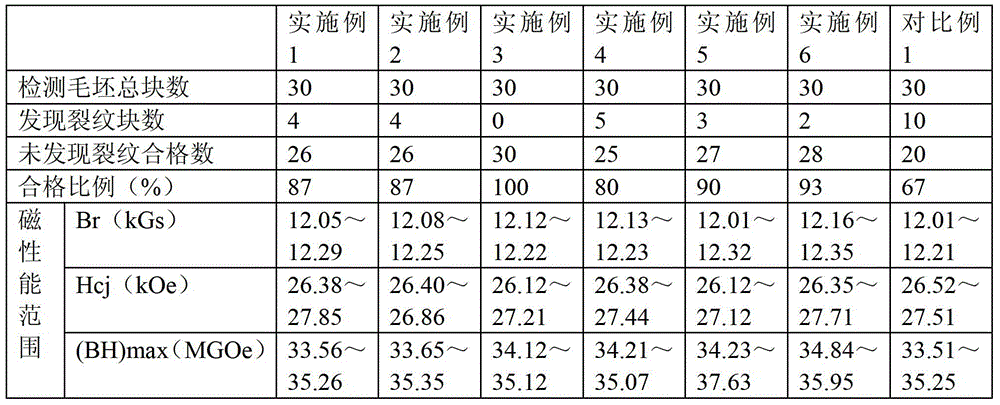

Embodiment 1

[0023] Example 1: After the hydrogen explosion process, the medium-sized powder with a hydrogen content of 2000-2100 ppm is measured, and after jet milling, 30 square magnets with a weight of 800 g are pressed, and the blanks are stacked in a closed sintering box with a sealed cover , put the material box into the vacuum sintering furnace, and wait until the sintering furnace is vacuumed to 10 -1 After Pa, start to heat up to the first-stage degassing temperature of 300°C, and control the heating rate at 5°C / min. After reaching the degassing temperature of the first stage, keep it warm for 1.5h, then continue to heat up to the degassing temperature of the second stage at 700°C, and control the heating rate at 5°C / min. When the temperature reaches the degassing temperature of the second stage, charge a certain amount Argon gas with a purity of more than 99.9% forms a pressure of 1000Pa in the furnace, heats it for 3 hours, vacuumizes after the heat preservation is over, and con...

Embodiment 2

[0025] Example 2: After the hydrogen explosion process, the medium-sized powder with a hydrogen content of 2000-2100 ppm is measured, and after jet milling, 30 square magnets with a weight of 1000 g are pressed, and the blanks are stacked in a sealed sintering box with a sealed cover , put the material box into the vacuum sintering furnace, and wait until the sintering furnace is vacuumed to 10 -1After Pa, start to heat up to the first-stage degassing temperature of 400°C, and the temperature rise rate is controlled at 3°C / min. After reaching the degassing temperature of the first stage, keep it warm for 1.0h, then continue to heat up to the degassing temperature of the second stage at 800°C, and control the heating rate at 3°C / min. When the temperature reaches the degassing temperature of the second stage, charge a certain amount The argon gas with a purity of more than 99.9% forms a pressure of 2500Pa in the furnace and holds it for 4.5 hours. After the heat preservation is ...

Embodiment 3

[0027] Example 3: After the hydrogen explosion process, the medium-sized powder with a hydrogen content of 2000-2100 ppm is measured, and after jet milling, 30 square magnets with a weight of 1500 g are pressed, and the blanks are stacked in a sealed sintering box with a sealed cover , put the material box into the vacuum sintering furnace, and wait until the sintering furnace is vacuumed to 10 -1 After Pa, start to heat up to the first-stage degassing temperature of 450°C, and the temperature rise rate is controlled at 7°C / min. After reaching the degassing temperature of the first stage, keep it warm for 1.5 hours, then continue to heat up to the degassing temperature of the second stage at 1000°C, and control the heating rate at 7°C / min. When the temperature reaches the degassing temperature of the second stage, charge a certain amount Argon gas with a purity of more than 99.9% forms a pressure of 1500Pa in the furnace, heats it for 5 hours, vacuumizes after the heat preserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com