Landfill type biogas generator

A technology for biogas generators and exhaust parts, which is applied in the field of biogas generators and landfill biogas generators. It can solve problems such as biogas leakage and potential safety hazards, and achieve enhanced stability, improved safety, and accelerated heat discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

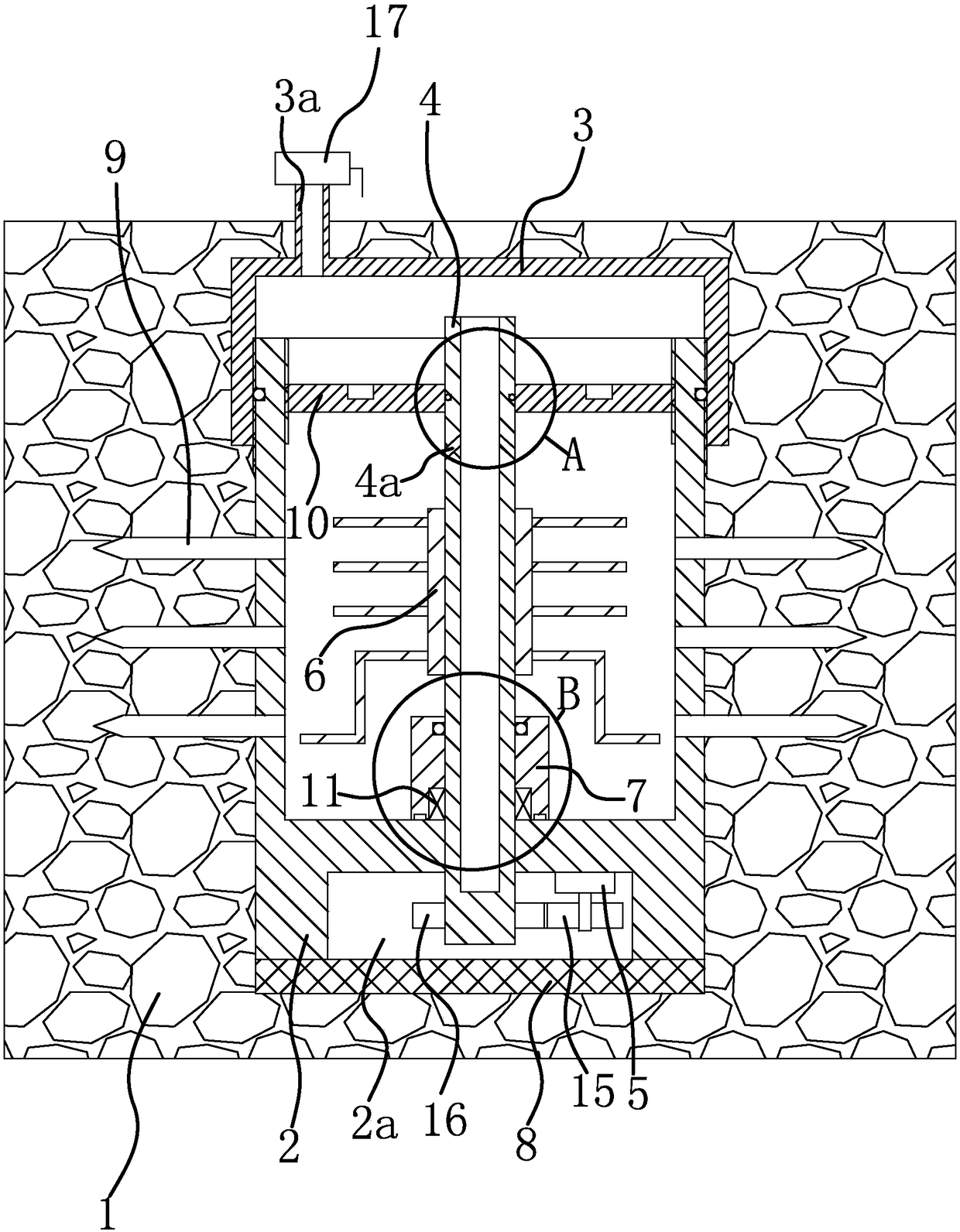

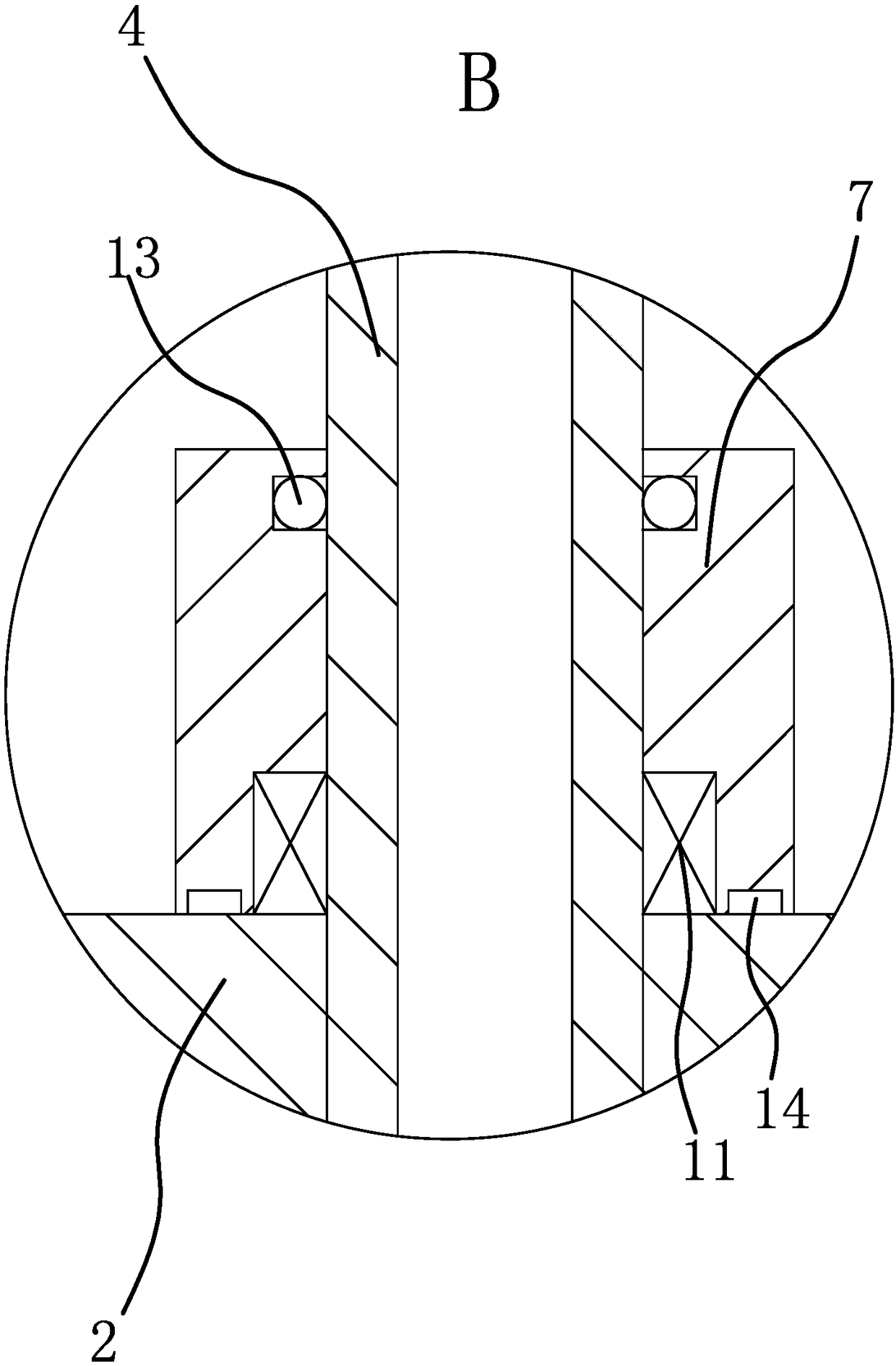

[0025] Such as Figure 1 to Figure 3 As shown, the landfill biogas generator is buried in the soil layer 1, which consists of a barrel body 2, a barrel cover 3, a rotating shaft 4, a reduction motor 5, a stirring blade 6, a support cylinder 7, a filter screen 8, a positioning rod 9, etc. composition. Wherein, the positioning rod 9 is made of heat-conducting material, and the heat-conducting material may be aluminum alloy or brass.

[0026] Specifically, the mouth of the bucket body 2 is set upward; In this embodiment, preferably the bucket cover 3 and the bucket body 2 are connected by a threaded structure, and an O-ring is provided between the bucket body 2 and the bucket cover 3 so that the two form a reliable seal.

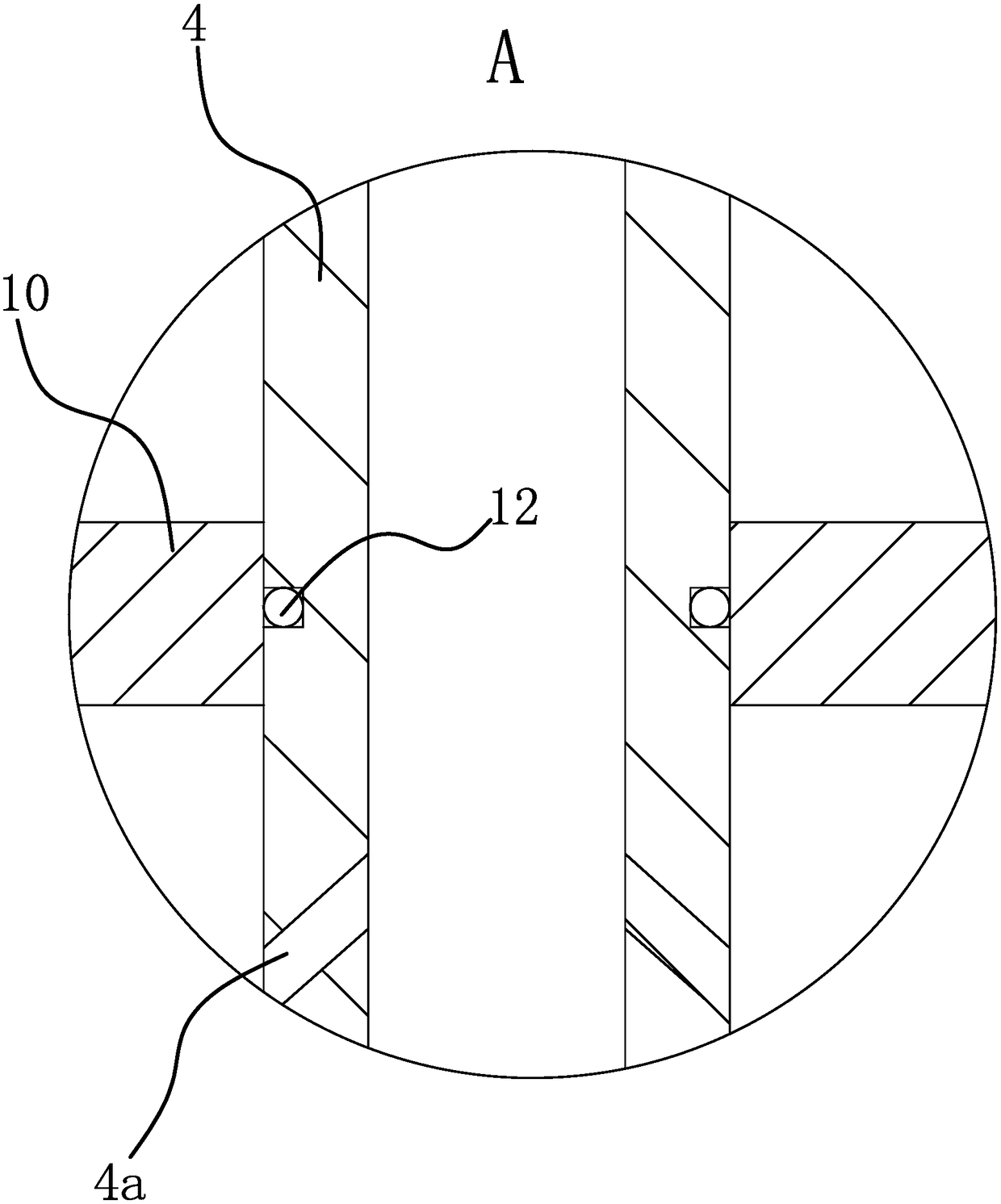

[0027] Such as figure 1 As shown, the barrel body 2 is screwed with an annular connecting seat 10, and the top wall of the connecting seat 10 is provided with a rotating hole for cooperating with a tool, so that the connecting seat 10 can be disassembled. T...

Embodiment 2

[0038] The structure and principle of the present embodiment two are basically the same as those of the first embodiment, except that the transmission mechanism includes a driving wheel connected to the main shaft of the reduction motor 5 and a driven wheel connected to the lower end of the rotating shaft 4, and the driving wheel and the driven wheel are connected to each other. The driving wheels are connected by a timing belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com