Combined bounding wall reutilizing building waste

A construction waste and combined technology, applied in the field of building components and construction waste recycling and reuse, and building materials, can solve problems such as large amount of engineering, achieve the effect of self-heavy, easy to popularize and apply, and alleviate the dilemma of recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

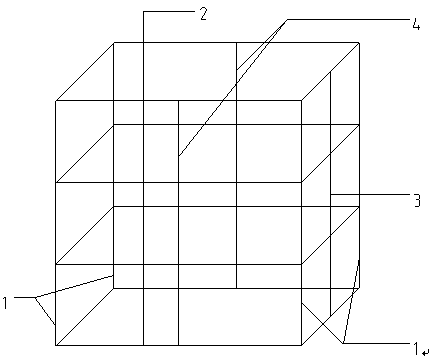

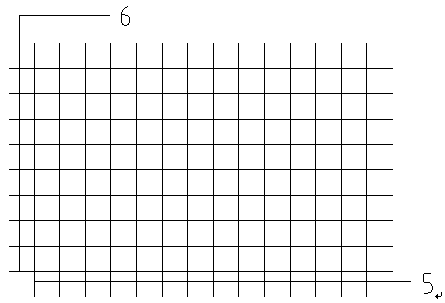

[0019] Using the present invention, taking the construction of one section of the wall as an example, material preparation: the steel column (1) adopts square steel pipe, the cross-sectional size is 100mm*100mm, the wall thickness is 10mm, and the length is 3m; 50mm, the thickness is 5mm; if figure 2 As shown, the steel mesh sheet is welded by longitudinally distributed steel bars (5) and horizontally distributed steel bars (6). The plane size is 1m*1.5m, the steel bar diameter is 12mm, the spacing is 100mm, and the steel bar level is third-grade steel.

[0020] Main construction process: After the site is leveled, set out the wires to determine the position of the steel columns (1). The vertical spacing of the steel columns (1) is 3m, and the horizontal spacing is 1m. After the foundation is completed, insert the steel columns (1) into the foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com