Manufacturing method of laminated tile assembly

A manufacturing method and component technology, applied in the manufacture of electrical components, semiconductor devices, final products, etc., can solve the problems of low production efficiency, many production steps, and long production lines, so as to improve production efficiency, simplify the process, and avoid the existence of shapes The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

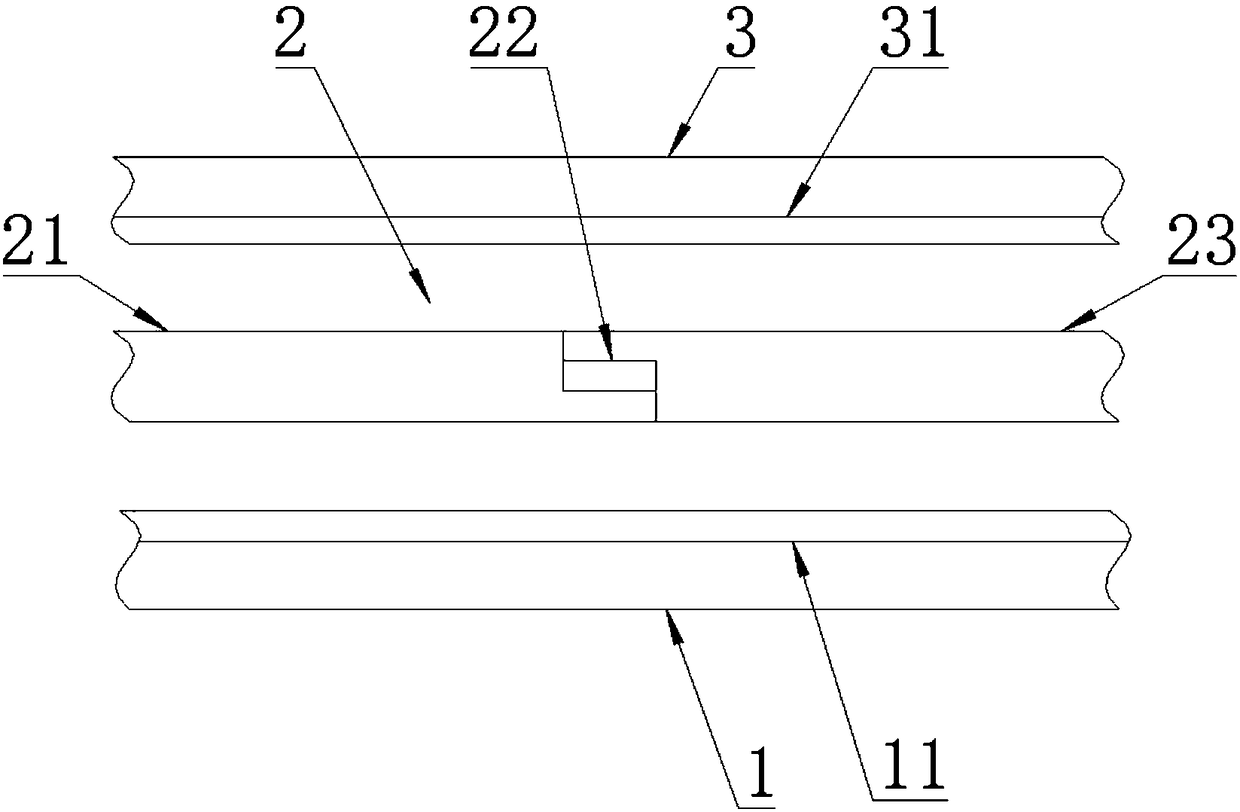

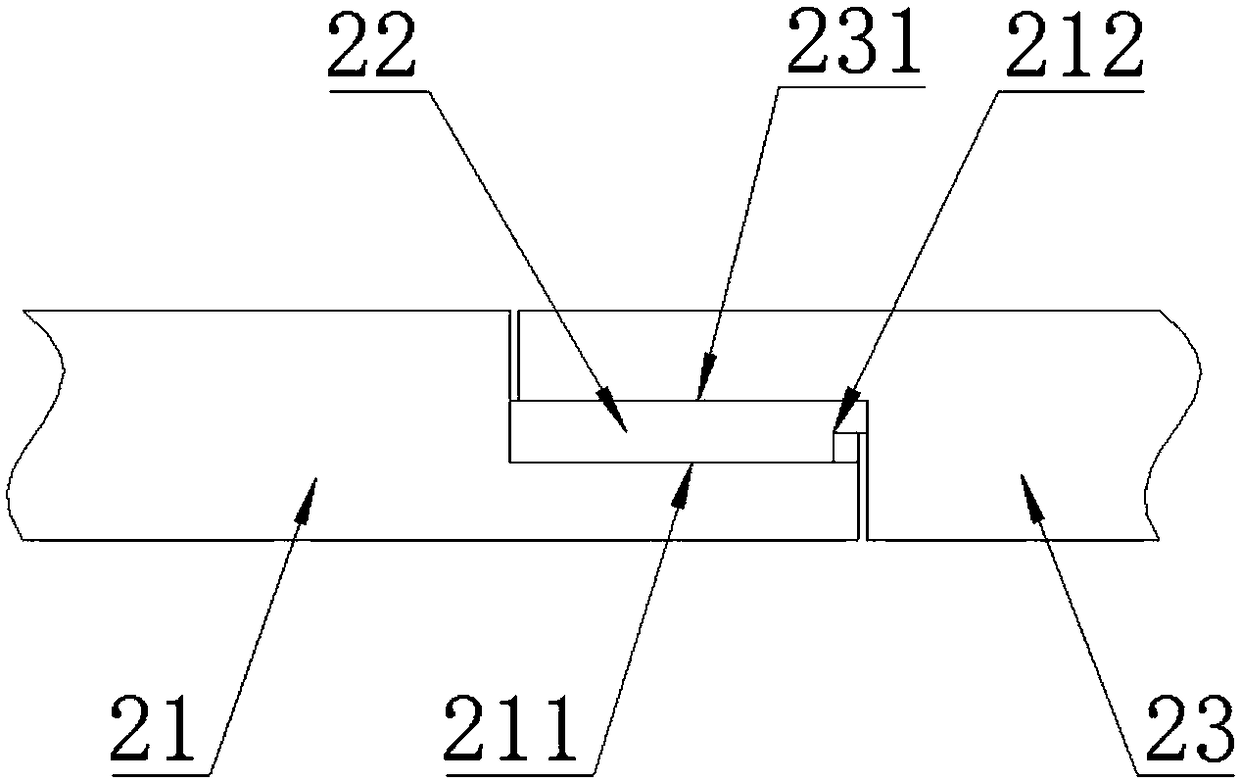

[0062] Furthermore, please also refer to Figure 2 to Figure 3 , as a specific embodiment of the manufacturing method of the shingled assembly provided by the present invention, the end of the first solar battery sheet 21 is provided with a first groove 211 with an open outer surface; at the end of the first solar battery sheet 21 Laying the welding layer 22 includes:

[0063] The solder layer 22 is laid in the first groove 211 .

[0064] By arranging the soldering layer 22 in the first groove 211, the thickness of the first solar cell sheet 21, the soldering layer 22 and the second solar cell sheet 23 is reduced, and the first solar cell sheet is avoided during the lamination process. 21. The thickness of the laminated portion of the welding layer 22 and the second solar battery sheet 23 is too large, and the force is concentrated, causing the first solar battery sheet 21 or the second solar battery sheet 23 to break. It is also possible to increase the thickness of the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com