Packaging method for polymer lithium ion battery cell

A technology of lithium-ion batteries and packaging methods, which is applied to small-sized batteries/battery packs, large-sized batteries/battery packs, batteries, etc., and can solve the problems of lower production efficiency, high rate of shell defective products, and easy generation of scrap products, etc. problems, to achieve the effect of improving the qualification rate and production efficiency, realizing automatic packaging production, and the method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

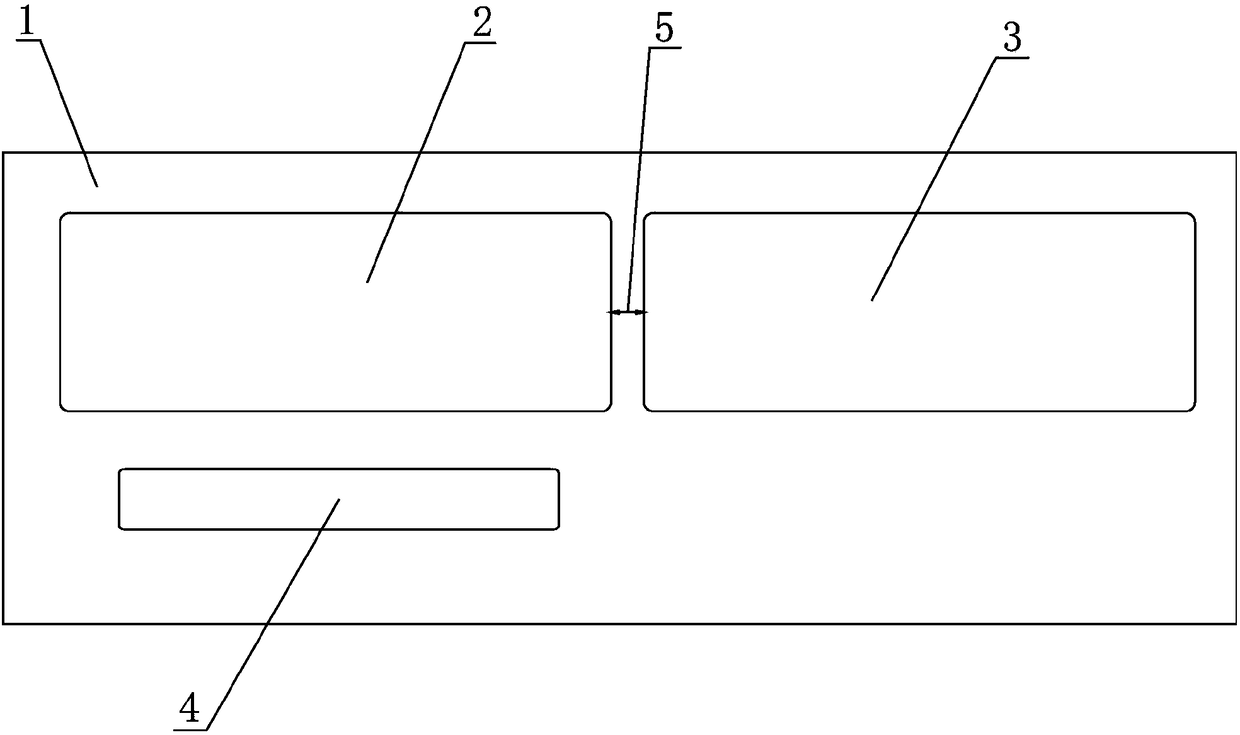

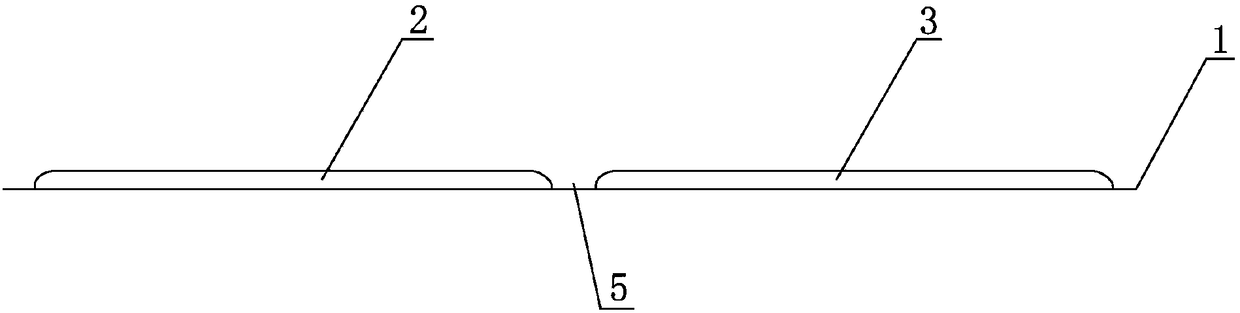

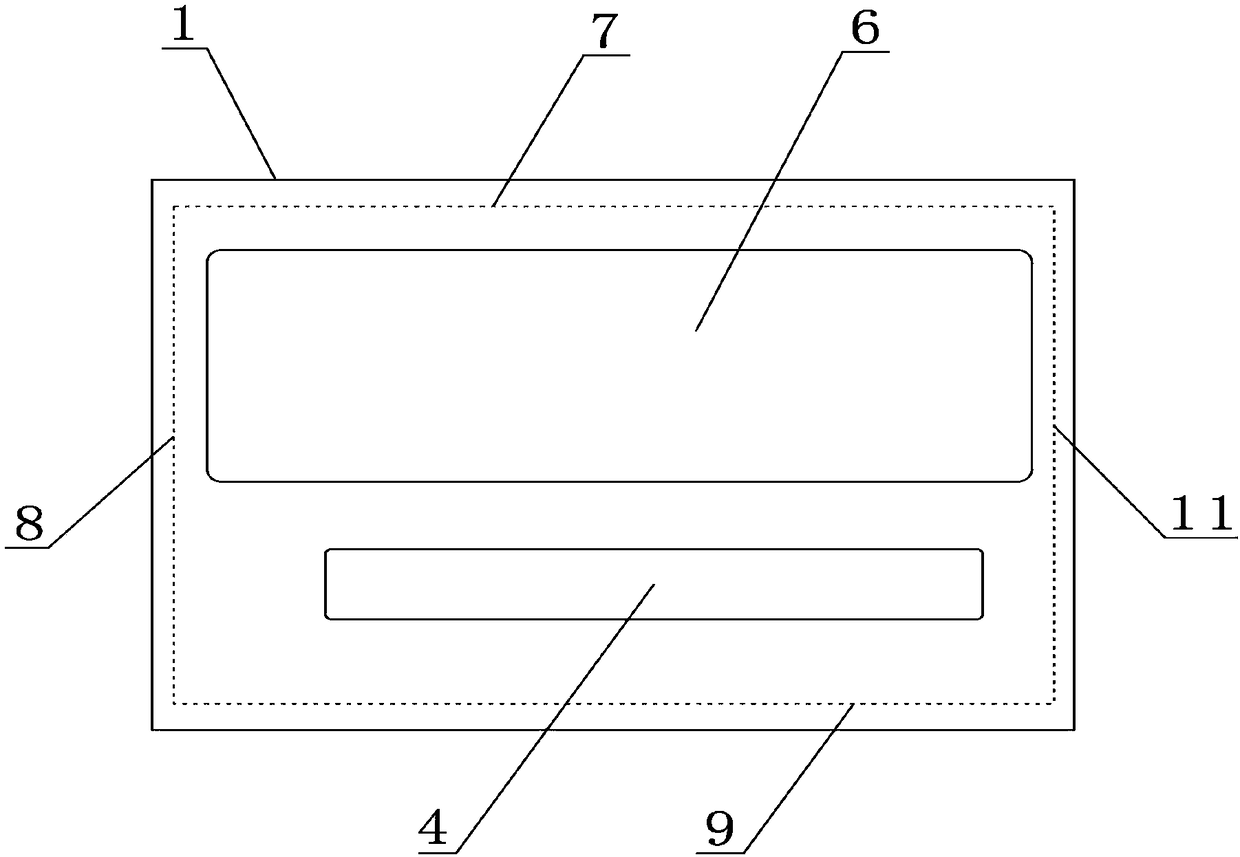

[0028] In this example, if Figure 1~4 Shown, a kind of encapsulation method for polymer lithium-ion battery cell, comprises the following steps:

[0029] Step 1. Stamping on the aluminum-plastic film to form the aluminum-plastic film stamping part 1 of the cell:

[0030] (a) Stamping depressions on the aluminum-plastic film to form the first battery housing cavity 2 and the second battery housing cavity 3, the first battery housing cavity 2 and the second battery housing cavity 3 are on the plane of the aluminum-plastic film They are mirror images of each other along the axis, and the battery cell containing cavity 6 formed by the combination of the first cell containing cavity 2 and the second cell containing cavity 3 matches the volume and shape of the polymer lithium-ion battery cell;

[0031] (b) Stamping and forming an airbag groove 4 beside the first cell accommodating chamber 2 on one side of the axis;

[0032] Step 2. Put the polymer lithium-ion battery cell into th...

Embodiment 2

[0041] In this example, if Figure 1~4 Shown, a kind of encapsulation method for polymer lithium-ion battery cell, comprises the following steps:

[0042] Step 1. Stamping on the aluminum-plastic film to form the aluminum-plastic film stamping part 1 of the cell:

[0043] (a) Stamping depressions on the aluminum-plastic film to form the first battery housing cavity 2 and the second battery housing cavity 3, the first battery housing cavity 2 and the second battery housing cavity 3 are on the plane of the aluminum-plastic film They are mirror images of each other along the axis, and the battery cell containing cavity 6 formed by the combination of the first cell containing cavity 2 and the second cell containing cavity 3 matches the volume and shape of the polymer lithium-ion battery cell;

[0044] (b) Punching and forming an air bag groove 4 next to the first cell accommodating cavity 2 or the second cell accommodating cavity 3 on one side of the axis;

[0045]Step 2. Put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com