Equipment and method for batch preparation of microcapsules

A microcapsule and batch technology, applied in the directions of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of complex device, easy pollution, inconvenient removal of formed microcapsules, etc. Simple and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

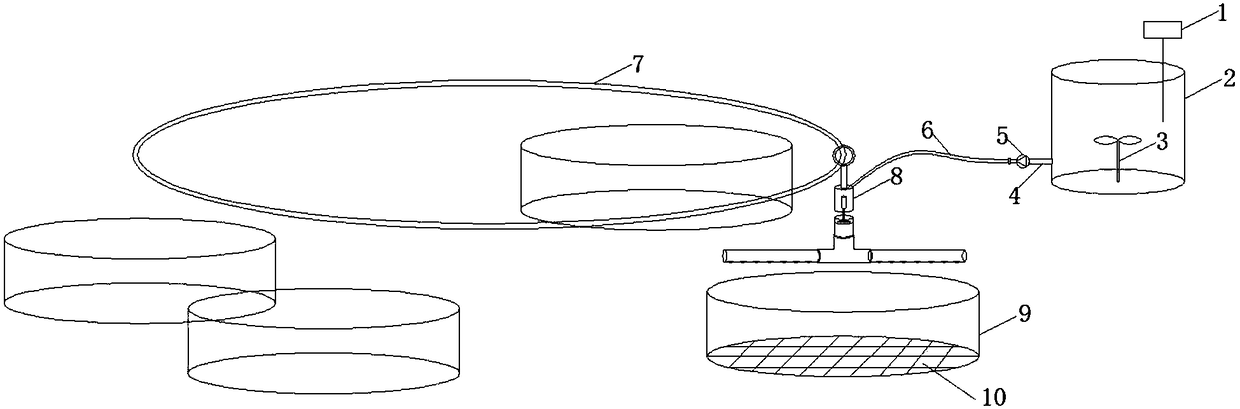

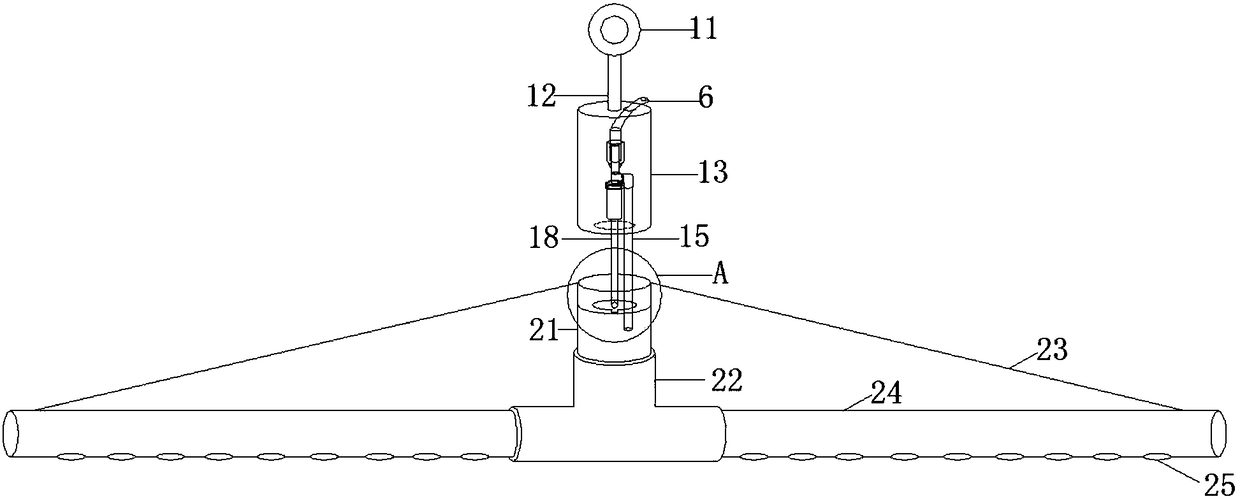

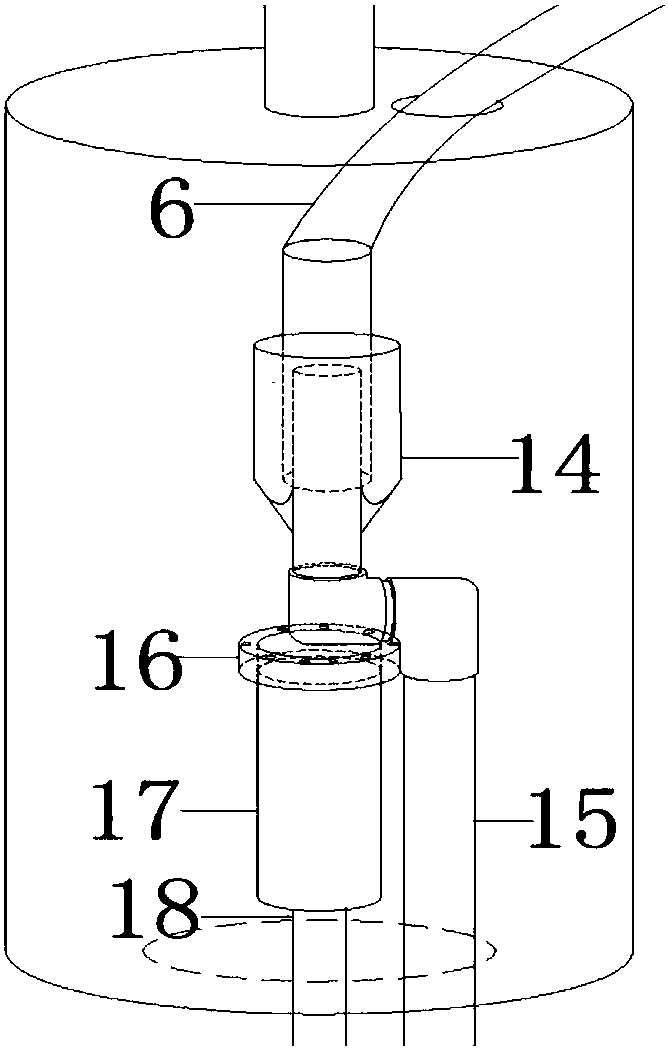

[0039] The overall structure of the equipment for preparing microcapsules in batches according to the present invention can be found in figure 1 , The equipment includes: liquid supply container 2, liquid level controller 1, agitator 3, short outlet pipe 4, water pump 5 and plastic pipe 6 connected behind the water pump, stainless steel fixing ring 7, pulley 11, (stainless steel) vertical rod 12 And rotary distributor 8, receiving reaction container 9 and plastic net 10.

[0040] Such as figure 1 As shown, the liquid supply container 2 is provided with a liquid level controller 1 and an agitator 3, and the liquid supply container 2 is sequentially connected to the water pump 5 and the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com