Edge bonding machine for cutting textile fabric

A technology for textile fabrics and edge banding machines, which is used in textiles and papermaking, mechanical cleaning, fabric surface trimming, etc. It can solve the problems of poor flatness and cleanliness of fabrics, wrinkled fabrics, and reduced fabric quality, and achieve flatness and cleanliness. Good, to ensure smoothness, to ensure the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0020] Example.

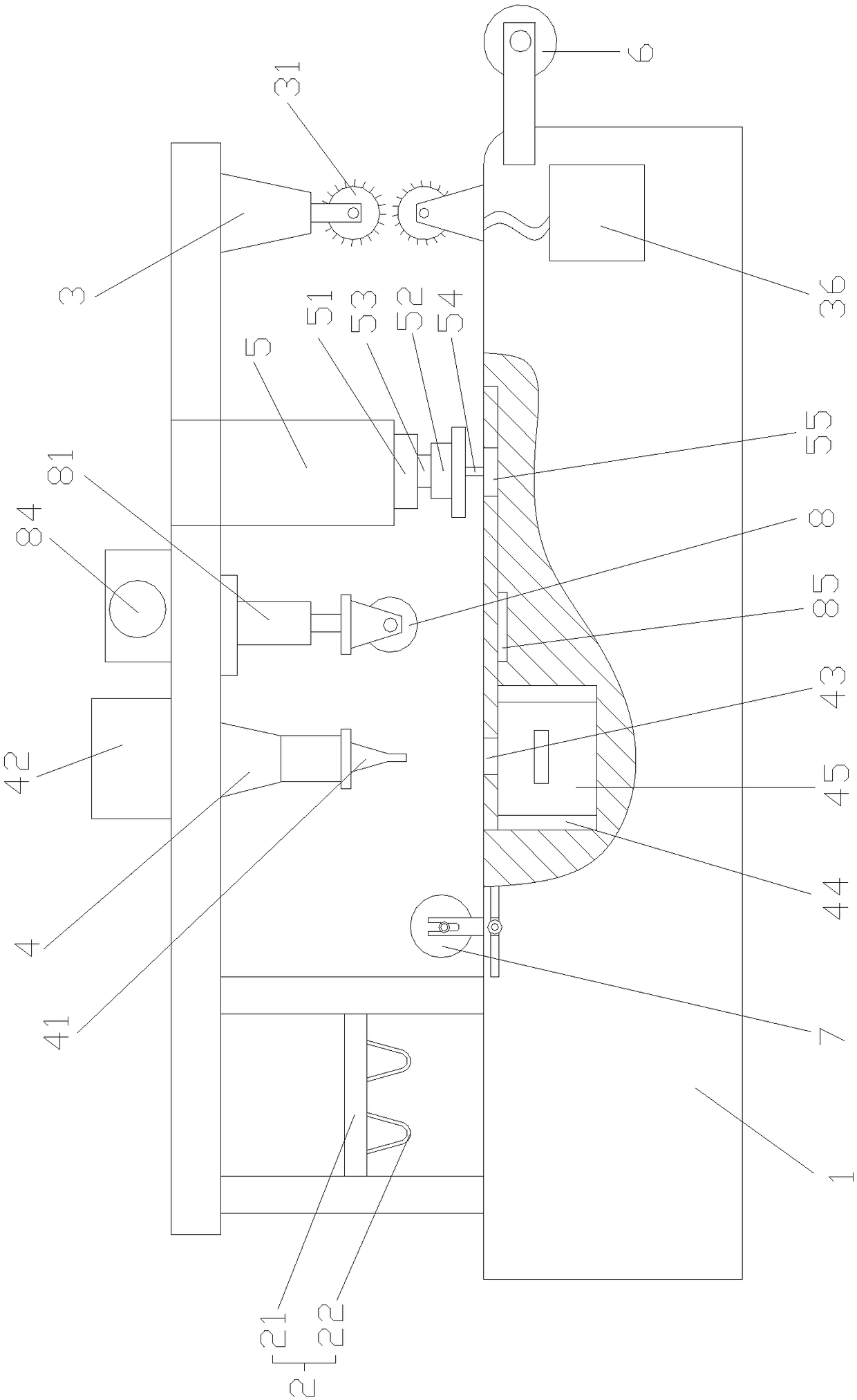

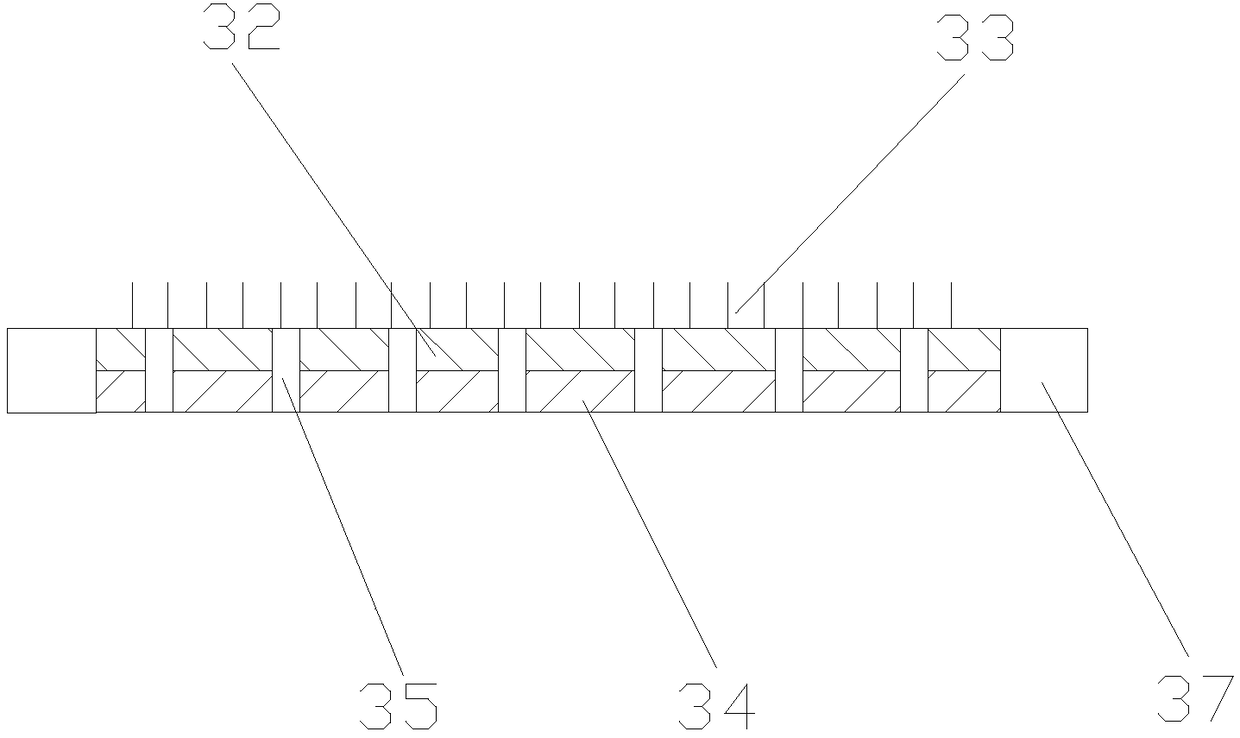

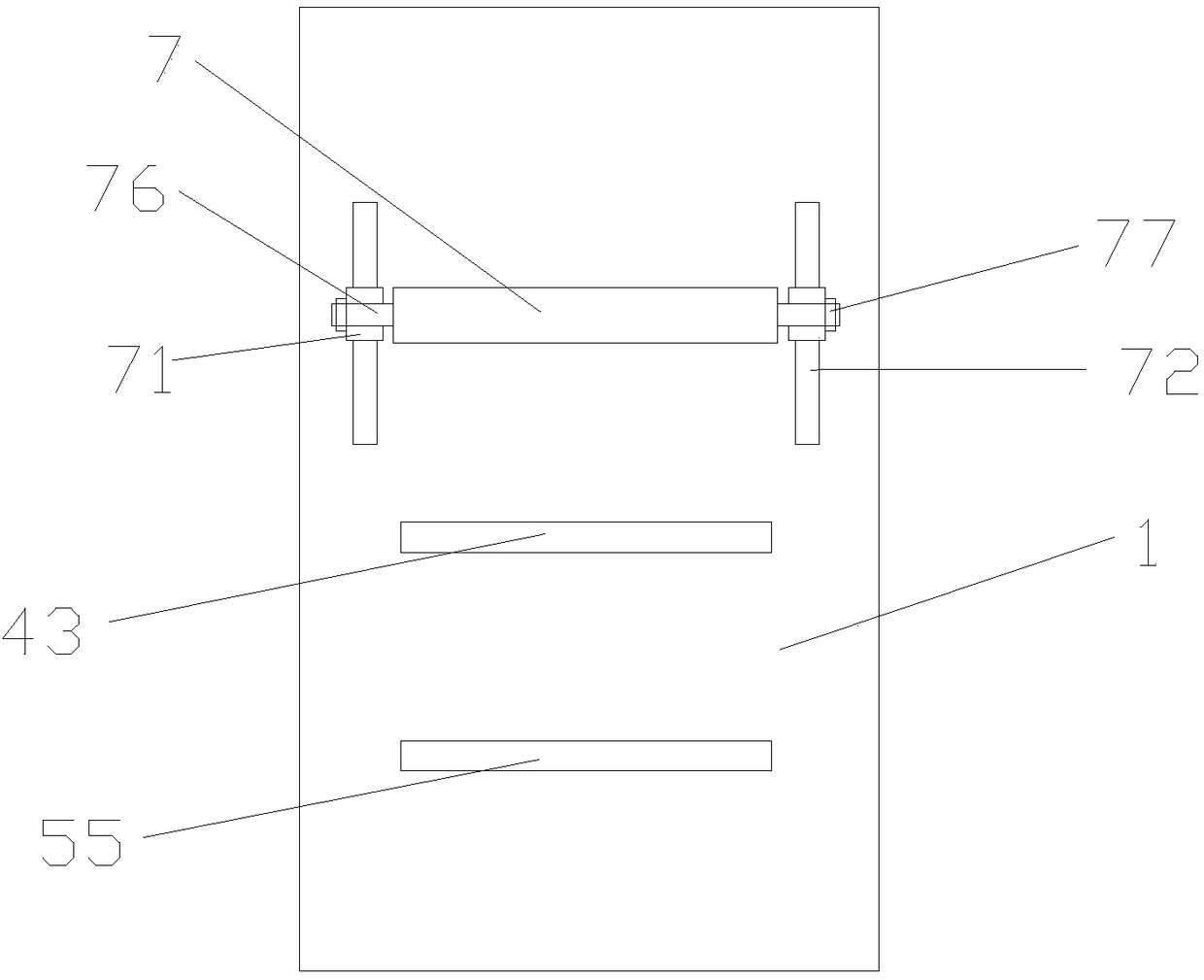

[0021] Such as figure 1 , figure 2 and image 3 As shown, a textile cloth cutting and edge banding machine includes a cloth passing platform 1, and the cloth passing platform 1 is sequentially provided with a feeding bracket 2, a gluing device 4, a cutting device 5, a cleaning device 3 and a cloth rolling roller 6 , the gluing device 4 includes a glue nozzle 41, the glue nozzle 41 is installed above the cloth passing platform 1, the glue nozzle 41 is connected with a glue material box 42 through a glue pipe, and the surface of the cloth passing platform 1 is located at the glue liquid There is a glue drop trough 43 directly below the nozzle 41, and a material receiving chamber 44 connected to the glue drop groove 43 is provided on one side of the cloth passing platform 1 below the glue drop groove 43, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap