Punching mechanism used for manufacturing water tank of solar water heater

A technology for solar water heaters and water tanks, which is applied in metal processing and other directions, can solve the problems of poor drilling quality of water tanks, low manufacturing efficiency, and inability to realize automatic production, etc., and achieve the effects of improving work efficiency, improving accuracy, and improving drilling quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

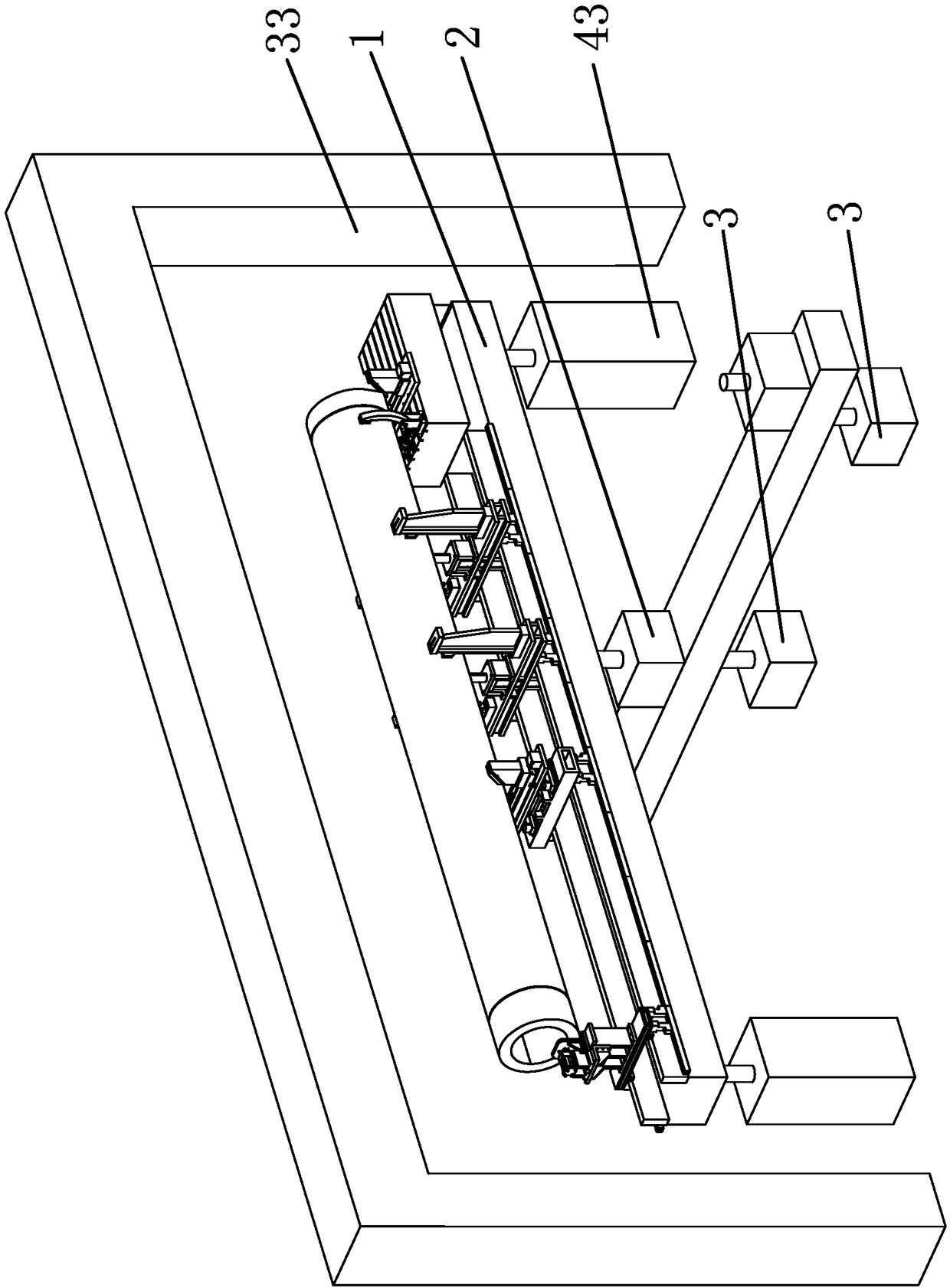

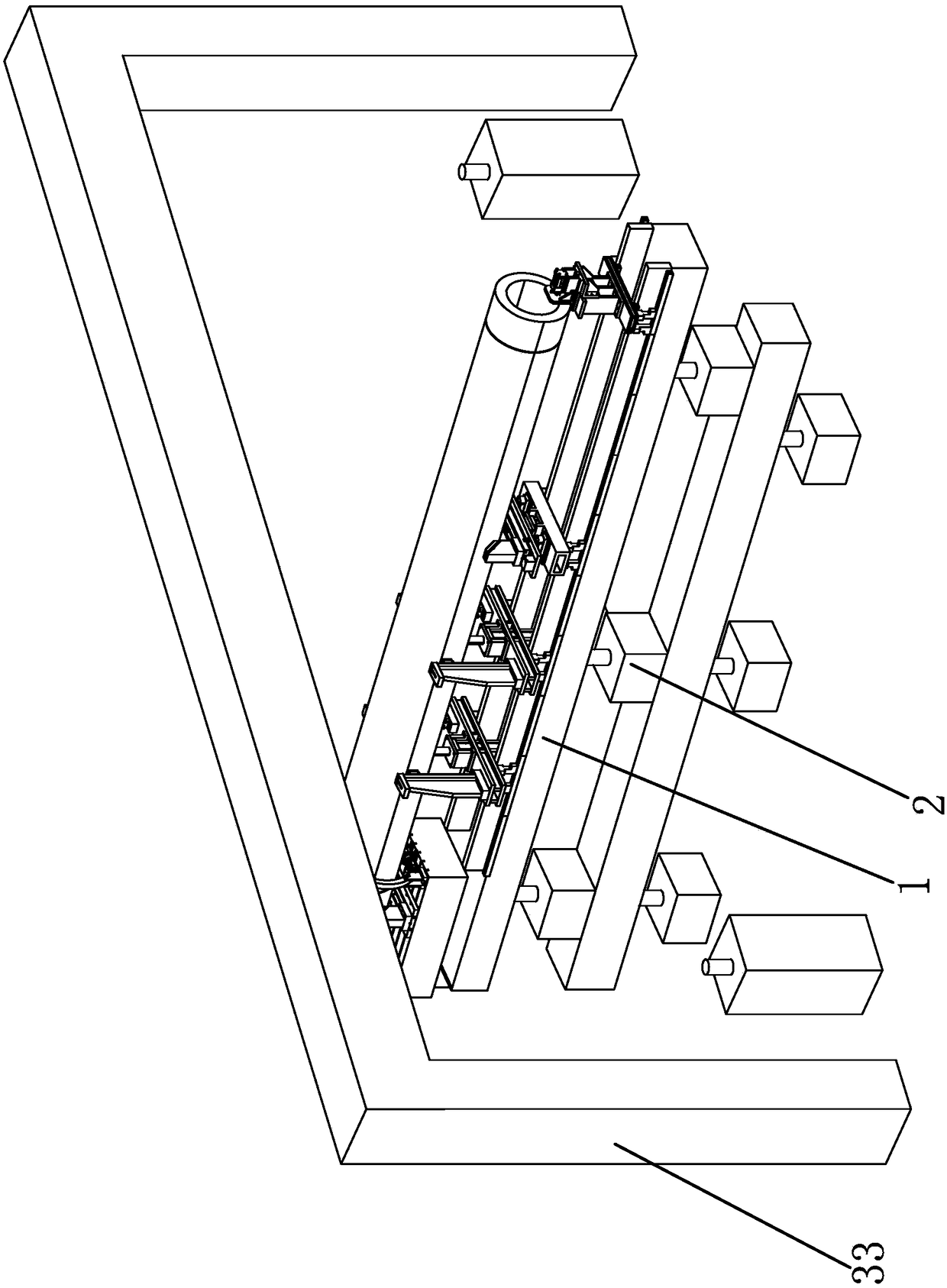

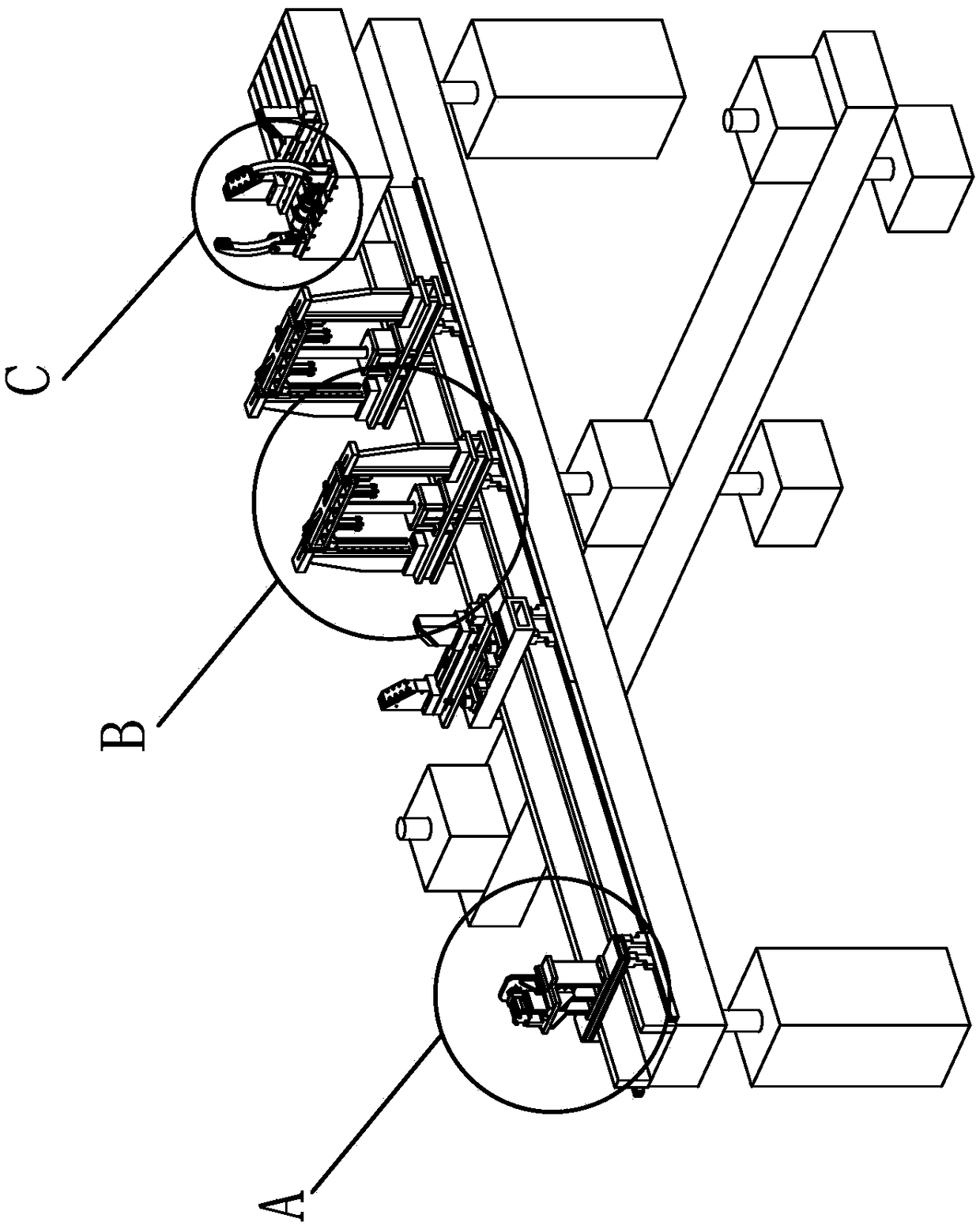

[0040] Such as Figure 1-9 As shown, a punching mechanism for manufacturing a solar water heater tank includes a workbench 1 on which a long strip-shaped working groove is provided. It is characterized in that the punching mechanism is arranged on the workbench 1 Above, comprise frame 33, and frame 33 is arranged on the top, and frame 33 is " 冂 " font, and frame 33 is provided with electric drill one 34 and electric drill two 35, and frame 33 is provided with can drive electric drill one 34 and The mobile structure that electric drill two 35 moves left and right, is provided with the lifting structure that can drive electric drill one 34 and electric drill two 35 to move up and down on the frame 33.

[0041] Lifting struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com