Natural gas well fluid separator

A technology of natural gas and separator, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems that the plunger cannot go down, reduce the lifting efficiency of bottom-hole fluid accumulation, and increase the plunger leakage, etc., and achieve Easy to descend and ensure the effect of lifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

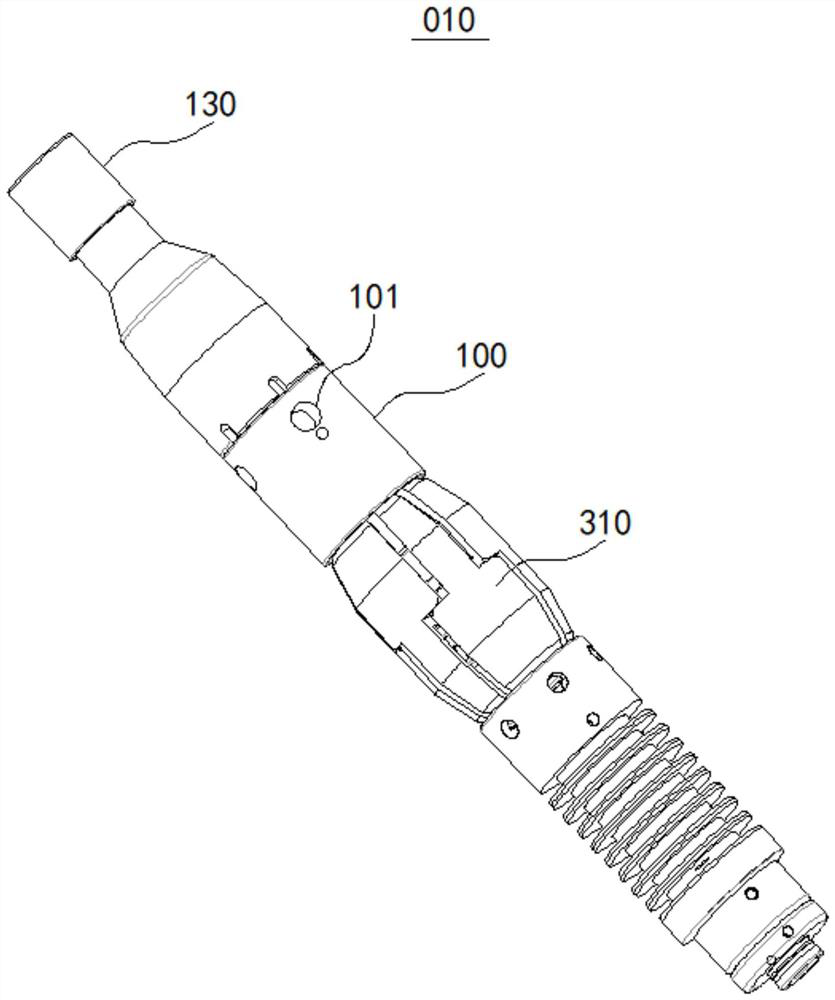

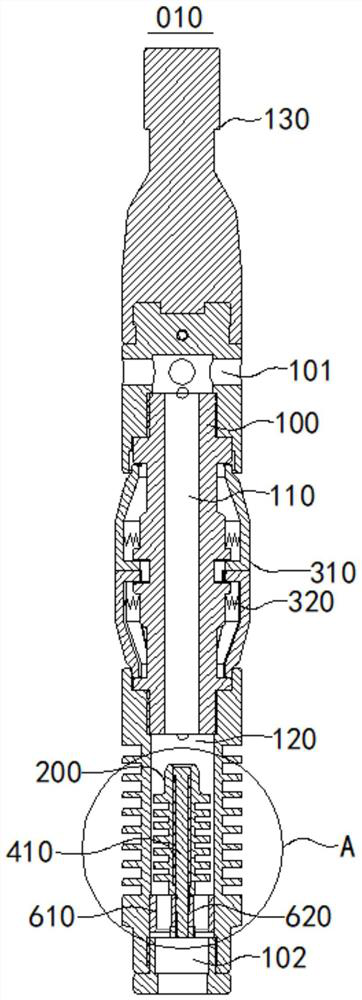

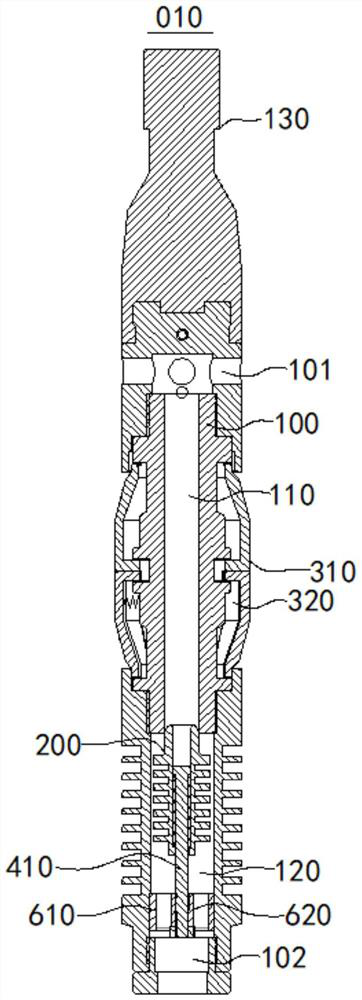

[0039] figure 1 A schematic diagram of the external structure of the natural gas well fluid separator 010 provided in this embodiment. figure 2 A schematic cross-sectional structure diagram of a natural gas well fluid separator 010 provided in this embodiment, in which the plugging column 200 is in an open position. image 3 A schematic cross-sectional structure diagram of a natural gas well fluid separator 010 provided in this embodiment, in which the plugging column 200 is located at the plugging position. Figure 4 yes figure 2 Enlarged view of A.

[0040] Please refer to Figure 1-Figure 4 , the natural gas well fluid separator 010 provided in this embodiment includes a mandrel 100, a plugging column 200 and a circumferential sealing mechanism.

[0041] The two axial ends of the mandrel 100 are respectively provided with an upper flow port 101 and a lower flow port 102 which communicate with the outside world, and along the direction from the upper flow port 101 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com