Internal mixer capable of cleaning rotor

An internal mixer and rotor technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. Good extrusion effect, high cleaning efficiency and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

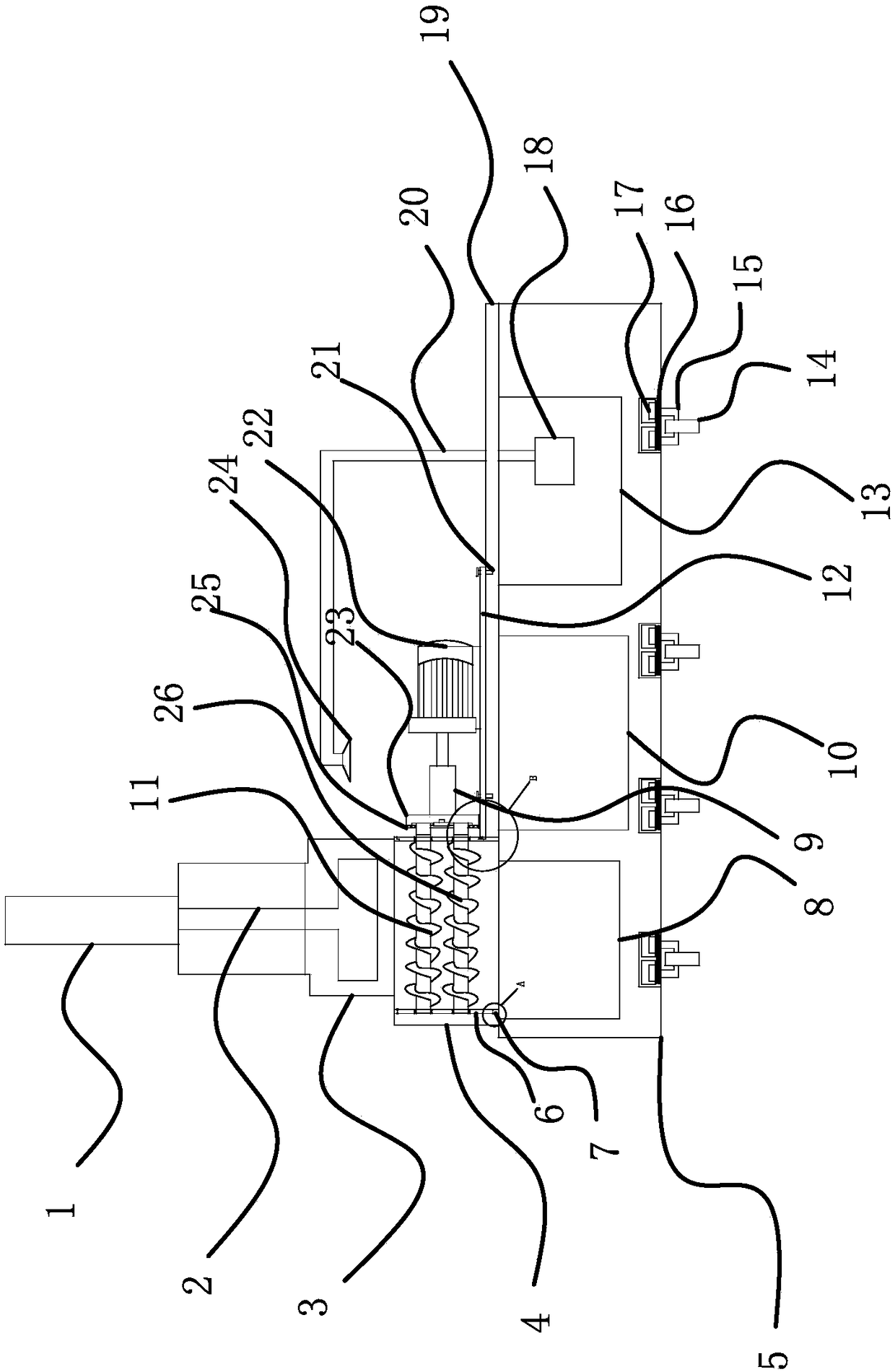

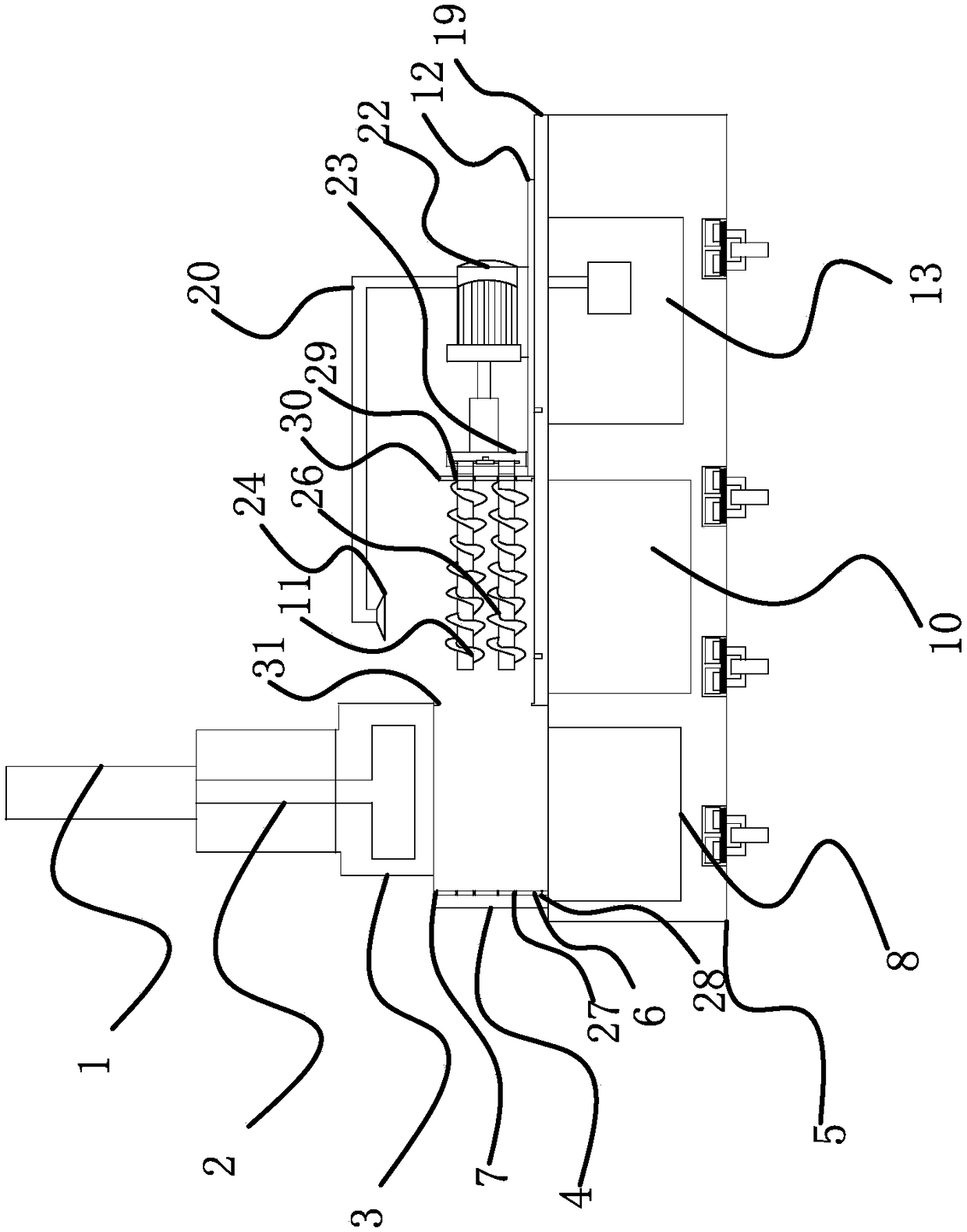

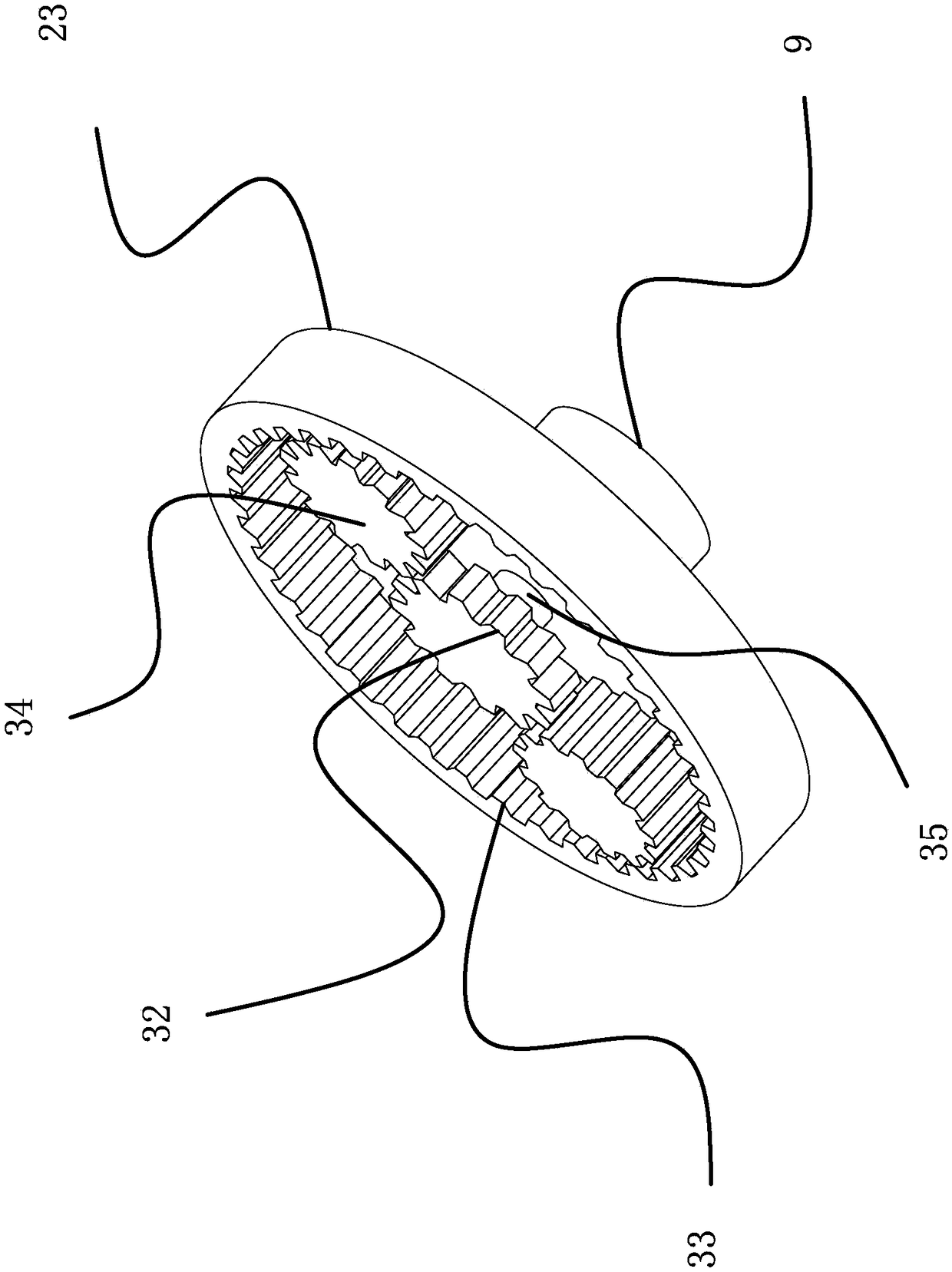

[0025] Such as Figure 1-6 As shown, the technical solution of the present invention is a internal mixer capable of cleaning the rotor, which includes a base 5, a first rotor 11, a second rotor 26, a motor 22, a planetary gear disc 23, a mixing chamber 4, and a dust collection chamber 3 and the cylinder 1, characterized in that the base 5 is provided with a slide rail 19, the slide rail 19 is slidably connected with a slide plate 12, the motor 22 is fixed on the slide plate 12, and the mixing chamber 4 is fixed on On the base 5, below the mixing chamber 4 is a receiving box 8 located in the base 5, the dust collecting chamber 3 is arranged on the upper end of the mixing chamber 4, the air cylinder 1 is arranged on the upper end of the dust collecting chamber 3, and the telescopic end of the air cylinder 1 is A pressing device 2 is provided. The pressing device 2 runs through the inner wall of the dust collecting chamber 3 and the mixing chamber 4. The output shaft of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com