3D printing head for material extrusion molding

A technology of extrusion molding and printing head, applied in the field of 3D printing, can solve the problems of unsatisfactory printing effect, clogged nozzle, affecting the precision and surface smoothness of parts, etc., to improve printing smooth performance, prevent material overflow, and optimize molding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

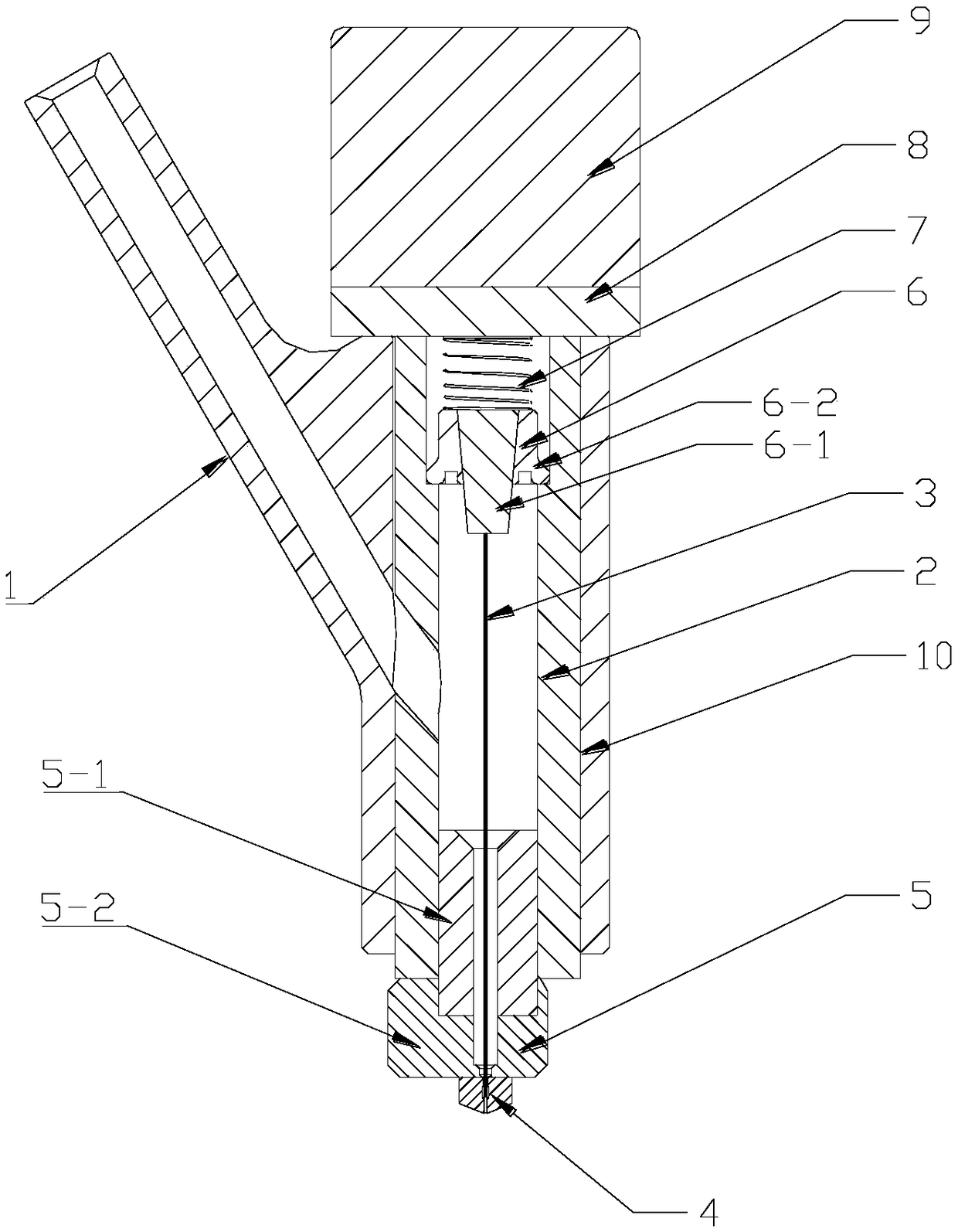

[0028] See attached figure 1 , a 3D printing head for material extrusion, including a wire feeding cavity 1, a thimble cavity 2, a sealing thimble 3, a printing nozzle 4, a heating module 5, a limit plug 6, a return spring 7, and an upper end cover 8 and electromagnet 9.

[0029] The thimble cavity 2 is vertically arranged, and the wire feeding cavity 1 is arranged on one side of the thimble cavity 2, and the wire feeding cavity 1 communicates with the thimble cavity 2 (the side wall of the thimble cavity is provided with a wire cavity outlet corresponding to the through hole), the heating module 5 is installed at the bottom of the thimble cavity 2, the heating module has a feeding inner channel, the bottom of the heating module is provided with the printing nozzle 4, the wire feeding cavity 1 , the thimble cavity 2, the inner channel of the heating module 5, and the printing nozzle 4 form a feeding channel.

[0030] The upper end cover 8 is installed on the top of the thimb...

Embodiment 2

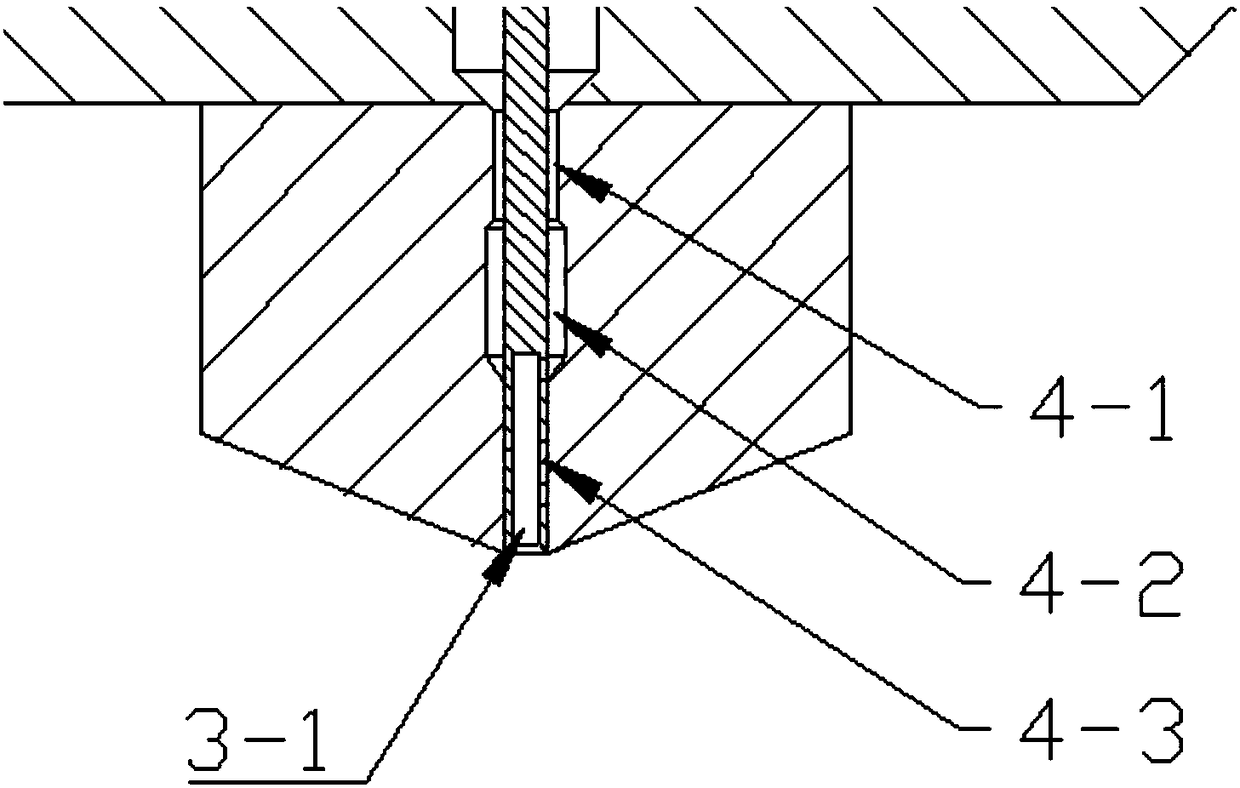

[0035] See attached figure 2Further, the discharge channel of the print nozzle 4 includes a first aperture section 4-1, a second aperture section 4-2 and a third aperture section 4-3 from top to bottom, and the diameter of the first aperture section is larger than The diameter of the sealing thimble, the diameter of the second aperture section is greater than the diameter of the first aperture section, and the diameter of the third aperture section is equal to the diameter of the sealing thimble; when the sealing thimble is pressed down, the molten material in the nozzle will Squeeze and squeeze to fill the second aperture section, and a part of the material will flow upward along the first aperture section (the diameter of the first aperture section is larger than the diameter of the sealing thimble), thereby reducing the amount of material extruded by the sealing thimble and preventing the formation of overflow drawing ; Finally, the third aperture section forms a seal with...

Embodiment 3

[0037] Further, the bottom of the sealing thimble 3 is provided with a section of hollow inner cavity 3-1, through which the hollow inner cavity further prevents material overflow: when the sealing thimble 3 is pressed down, the molten material in the nozzle will enter the sealing thimble 3 in the hollow cavity at the bottom, thereby effectively preventing the material from being extruded by the sealing thimble 3. After the sealing thimble 3 is lifted, the material in the hollow cavity of the sealing thimble 3 is heated to a molten state again, and drops from the hollow cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com