Integrated active and passive composite heave compensation device and working method thereof

A heave compensation and active compensation technology, which is applied in fluid pressure actuation devices, transportation and packaging, equipment for reducing ship motion, etc., can solve problems such as internal instrument failure and equipment instability, and achieve dynamic load suppression and smooth switching , strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

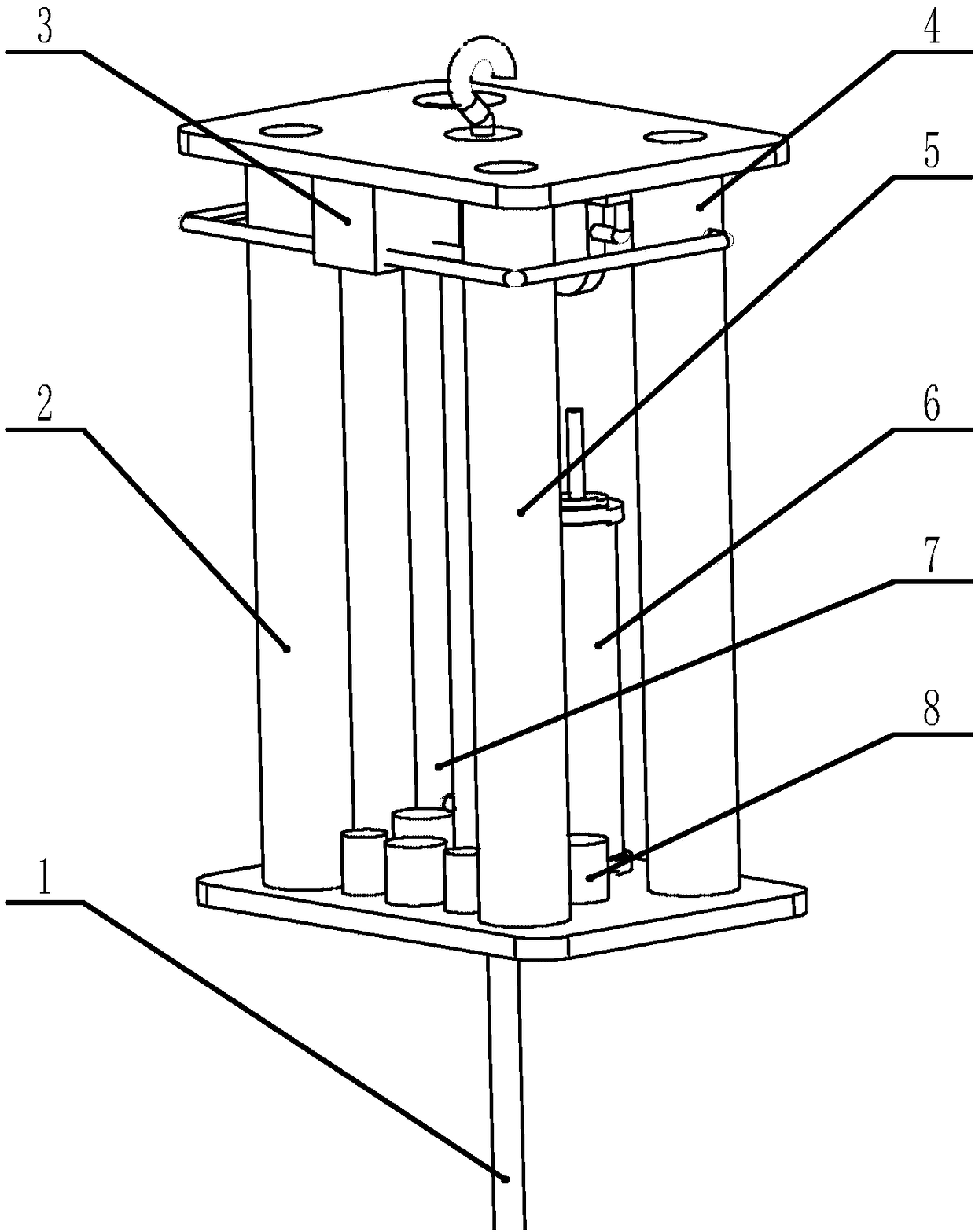

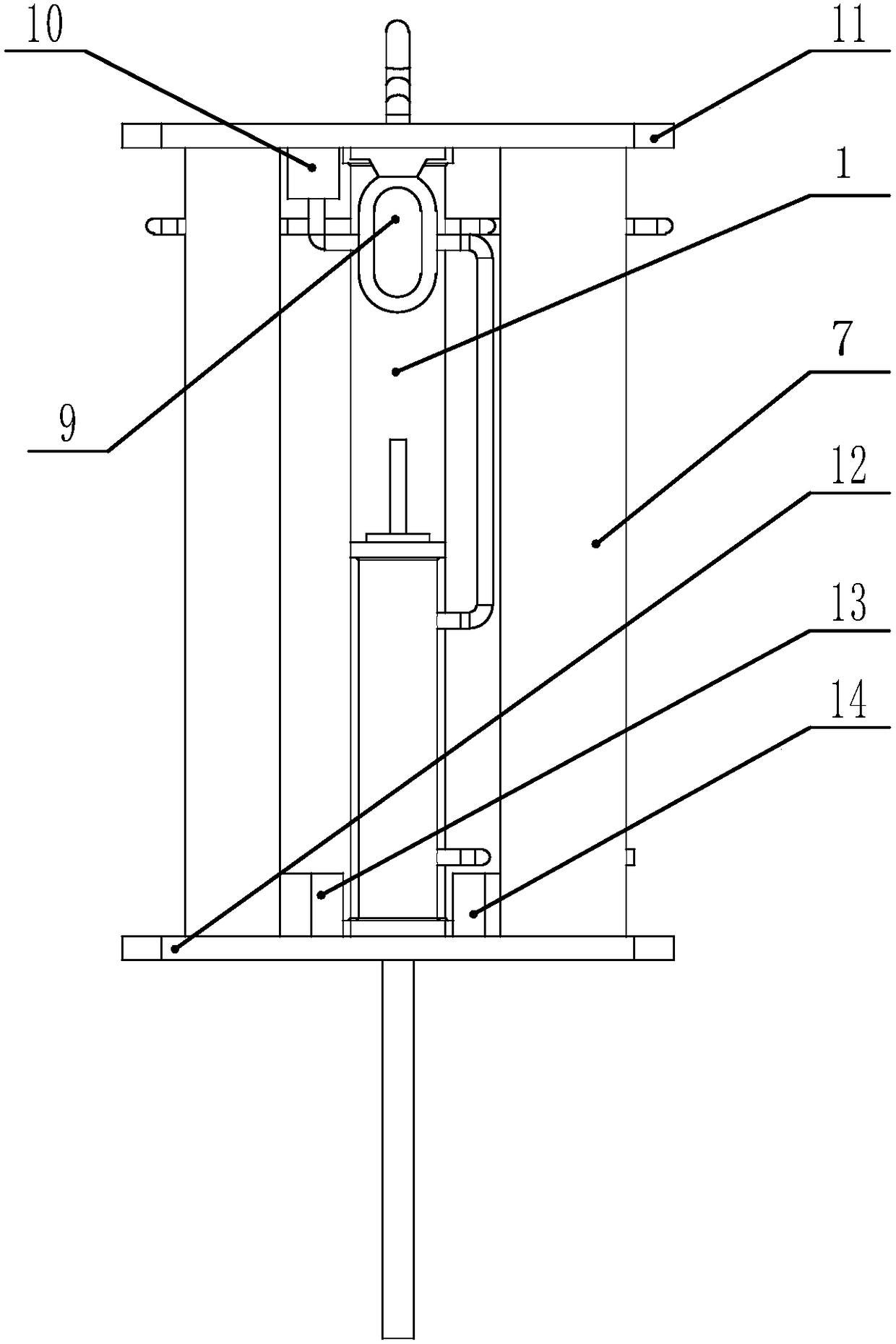

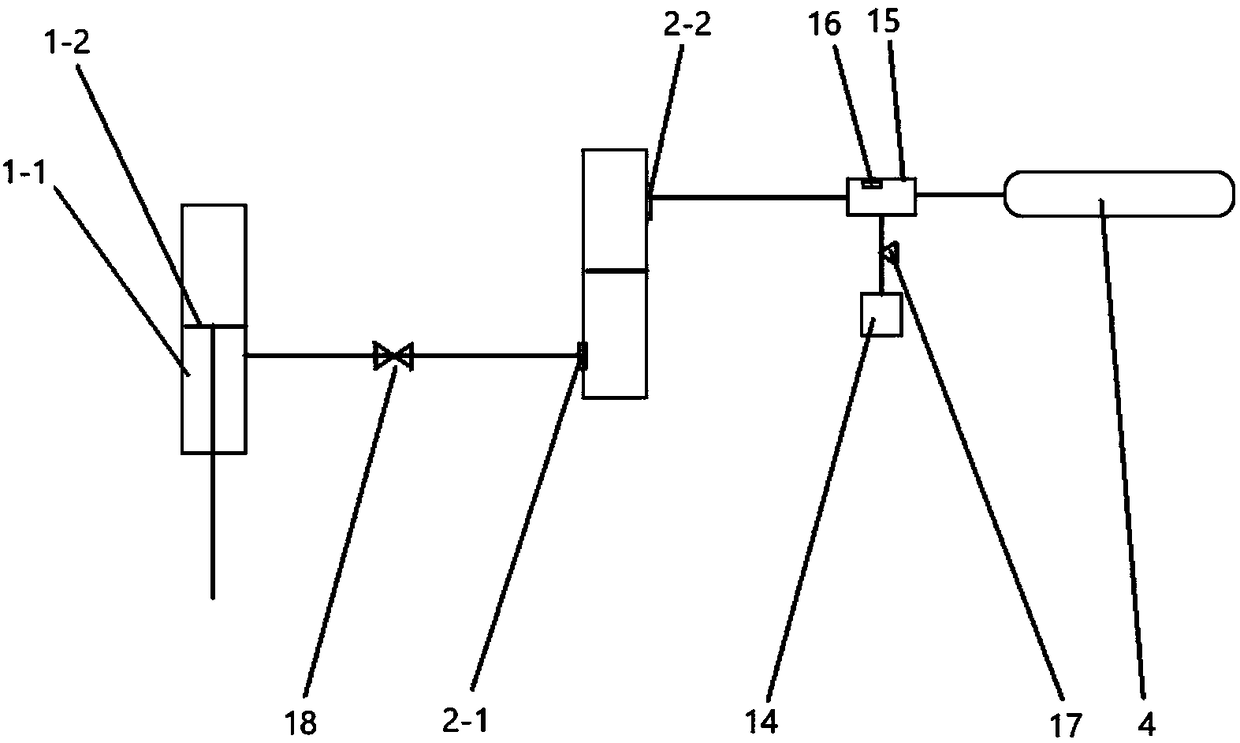

[0044] An integrated active-passive composite heave compensation device includes an active compensation system, a passive compensation system and a control drive module.

[0045] The active compensation system includes a main pump unit, a first hydraulic cylinder, and a second hydraulic cylinder. The control drive module is used to receive sea state signals and feedback signals and control the main pump unit. The main pump unit is connected to the first hydraulic cylinder. The main pump unit is used for Control the flow and pressure of the first hydraulic cylinder and feed back the information of the first hydraulic cylinder to the control drive module; the oil outlet of the first hydraulic cylinder is connected with the oil inlet of the second hydraulic cylinder through the oil circuit; the oil of the two hydraulic cylinders The opposite direction of motion enables active heave compensation.

[0046] The passive compensation system includes a gas-liquid accumulator and a gas ...

Embodiment 2

[0048] An integrated active and passive composite heave compensation device, the structure of which is as described in Embodiment 1, the difference is that the number of gas storage cylinders is 3, namely the first gas storage cylinder, the second gas storage cylinder, the second gas storage cylinder Three gas storage bottles, the first gas storage bottle is provided with a first air inlet and a first gas outlet, and the gas-liquid gas outlet of the gas-liquid accumulator is connected with the first air inlet through a pneumatic pipeline.

[0049] The second gas storage bottle is provided with a second gas port, the third gas storage bottle is provided with a third gas port, and the second gas port and the third gas port are respectively connected to the first gas outlet through a pneumatic pipeline. Set up three relatively independent gas storage cylinders, which can be selected according to the actual situation, and the second gas storage cylinder and the third gas storage cy...

Embodiment 3

[0051] An integrated active and passive composite heave compensation device, its structure is as described in Embodiment 2, the difference is that a switching valve is provided on the pneumatic pipeline between the second air port and the first air outlet, and the third air port is connected to the first air outlet. An on-off valve is arranged on the pneumatic pipeline between the air outlets. When the second gas storage cylinder or the third gas storage cylinder is needed, open the switch valve on the corresponding pipeline; when the second gas storage cylinder or the third gas storage cylinder is not needed, close the switch valve on the corresponding pipeline, at this time only The first gas cylinder works.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com