Method for removing copper ions in vanillin production wastewater

A technology for producing wastewater and vanillin, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as being unsuitable for heavy metals, not well suited for copper ion removal, and unsatisfactory heavy metal adsorption effects. , to achieve the effect of fast removal, less secondary pollution and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

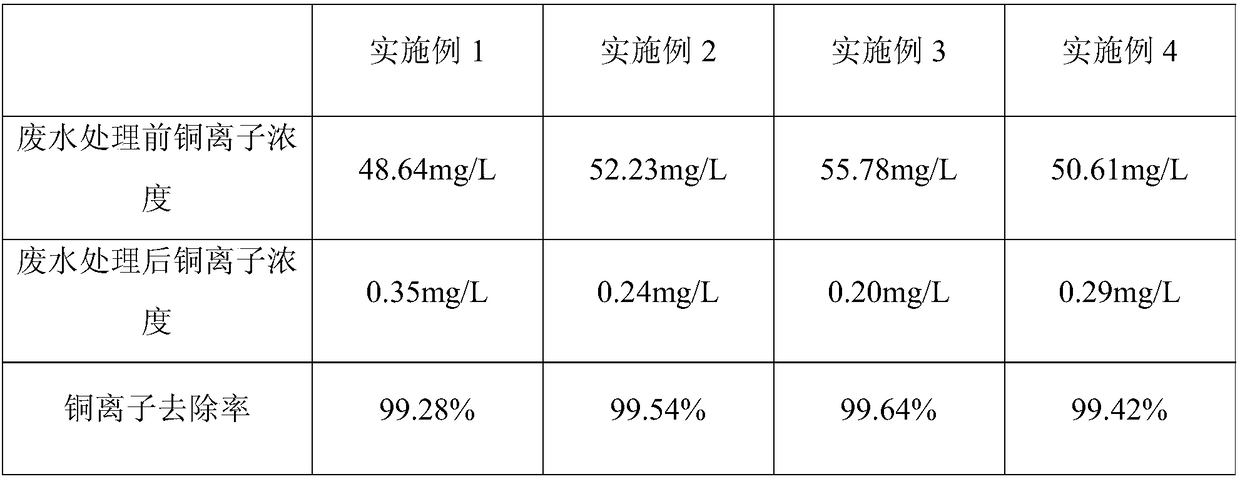

Embodiment 1

[0018] A method for removing copper ions in vanillin production wastewater, specifically comprising the following steps:

[0019] (1) Add sodium hydroxide to 1L of acidic vanillin wastewater after the main organic substances have been removed, and adjust the pH value to 7.5; the copper ion concentration in the vanillin wastewater is measured to be 48.64mg / L, and the sodium ion concentration is 92g / L, COD Cr It is 62mg / L.

[0020] (2) Preparation of thiacalixarene modified adsorption resin: Weigh 46.5 g of D-101 non-polar resin, wash it with deionized water three times, and dry it at 50°C for later use; weigh p-tert-butylthia Dissolve 3.5 g of calix[6]arene in 300 mL of chloroform, and oscillate ultrasonically for 1 hour to obtain a chloroform solution of p-tert-butylthiacalix[6]arene; p-tert-butylthiacalix[6]arene chloroform solution, stirred at 0°C for 24 hours, then separated by filtration, and dried at 50°C to obtain thiacalixarene-modified adsorption resin (the content ...

Embodiment 2

[0026] A method for removing copper ions in vanillin production wastewater, specifically comprising the following steps:

[0027] (1) Add sodium hydroxide to 1L of acidic vanillin wastewater after the main organic matter has been removed, and adjust the pH value to 8; the measured copper ion concentration in the vanillin wastewater is 52.23mg / L, and the sodium ion concentration is 95g / L, COD Cr It is 75mg / L.

[0028] (2) Preparation of thiacalixarene modified adsorption resin: Weigh 45.5 g of D-101 non-polar resin, wash it with deionized water three times, and dry it at 50°C for later use; weigh p-tert-butylthia Dissolve 4.5 g of calix[6]arene in 300 mL of chloroform, and oscillate ultrasonically for 1 hour to obtain a chloroform solution of p-tert-butylthiacalix[6]arene; add the dried D-101 non-polar resin to the above p-tert-butylthiacalix[6]arene chloroform solution, stirred at 0°C for 24 hours, then separated by filtration, and dried at 50°C to obtain thiacalixarene-mod...

Embodiment 3

[0034] A method for removing copper ions in vanillin production wastewater, specifically comprising the following steps:

[0035] (1) Add sodium hydroxide to 1L of acidic vanillin wastewater after the main organic substances have been removed, and adjust the pH value to 7.7; the copper ion concentration in the vanillin wastewater is measured to be 55.78mg / L, and the sodium ion concentration is 89g / L, COD Cr It is 82mg / L.

[0036] (2) Preparation of thiacalixarene modified adsorption resin: Weigh 45 g of D-101 non-polar resin, rinse with deionized water three times, and dry at 50°C for later use; weigh p-tert-butylthiacalixarene [6] Dissolve 5 g of arene in 300 mL of chloroform, and vibrate ultrasonically for 1 hour to obtain a chloroform solution of p-tert-butylthiacalix[6]arene; Butylthiacalix[6]arene chloroform solution, stirred at 0°C for 24 hours, then filtered and separated, and dried at 50°C to obtain thiacalixarene modified adsorption resin (the content of which is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com