Waste liquid treatment device for use in hospital laboratory

A waste liquid treatment and laboratory technology, applied in the direction of pathogenic microorganism wastewater treatment, filtration treatment, special treatment goals, etc., can solve the problems of inability to carry out anti-virus treatment, reduce work efficiency, and incompleteness, and achieve high sterilization and disinfection efficiency. Improve efficiency and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

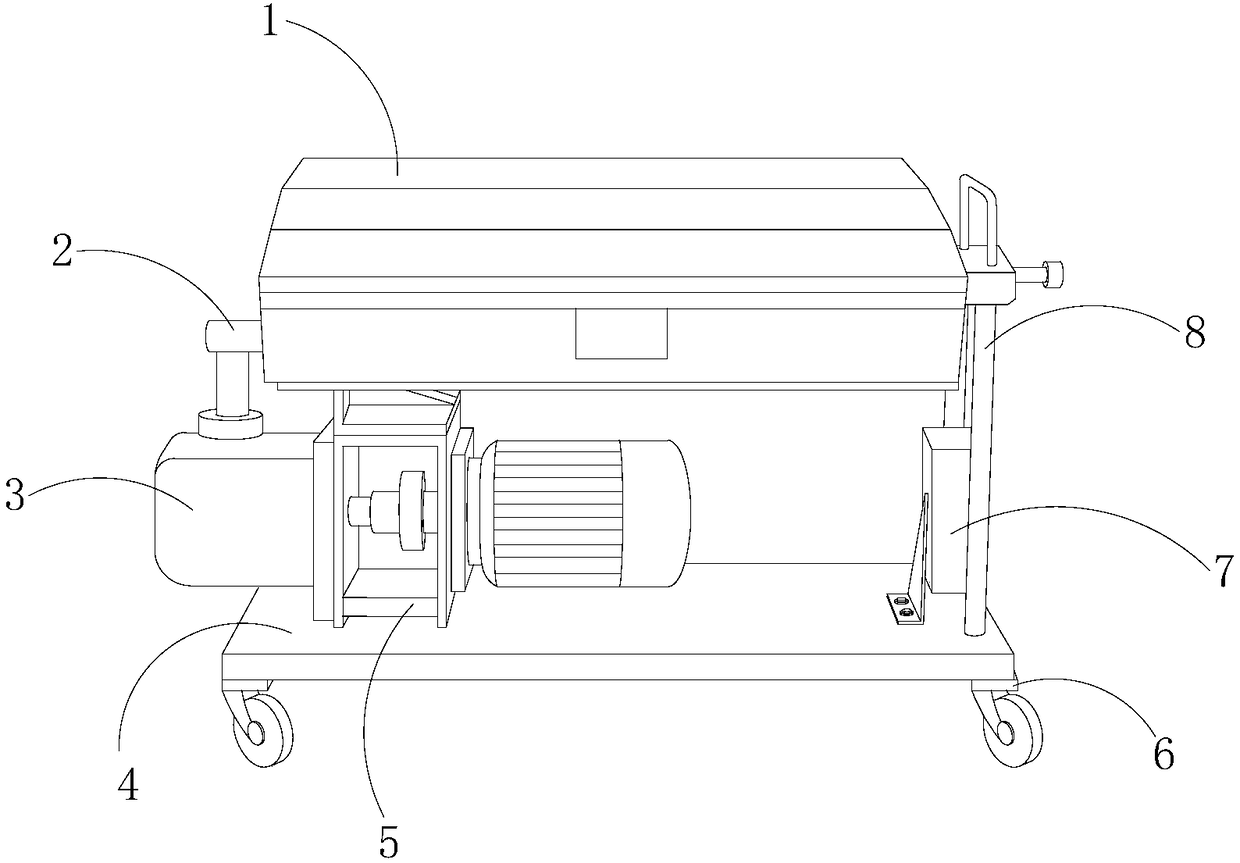

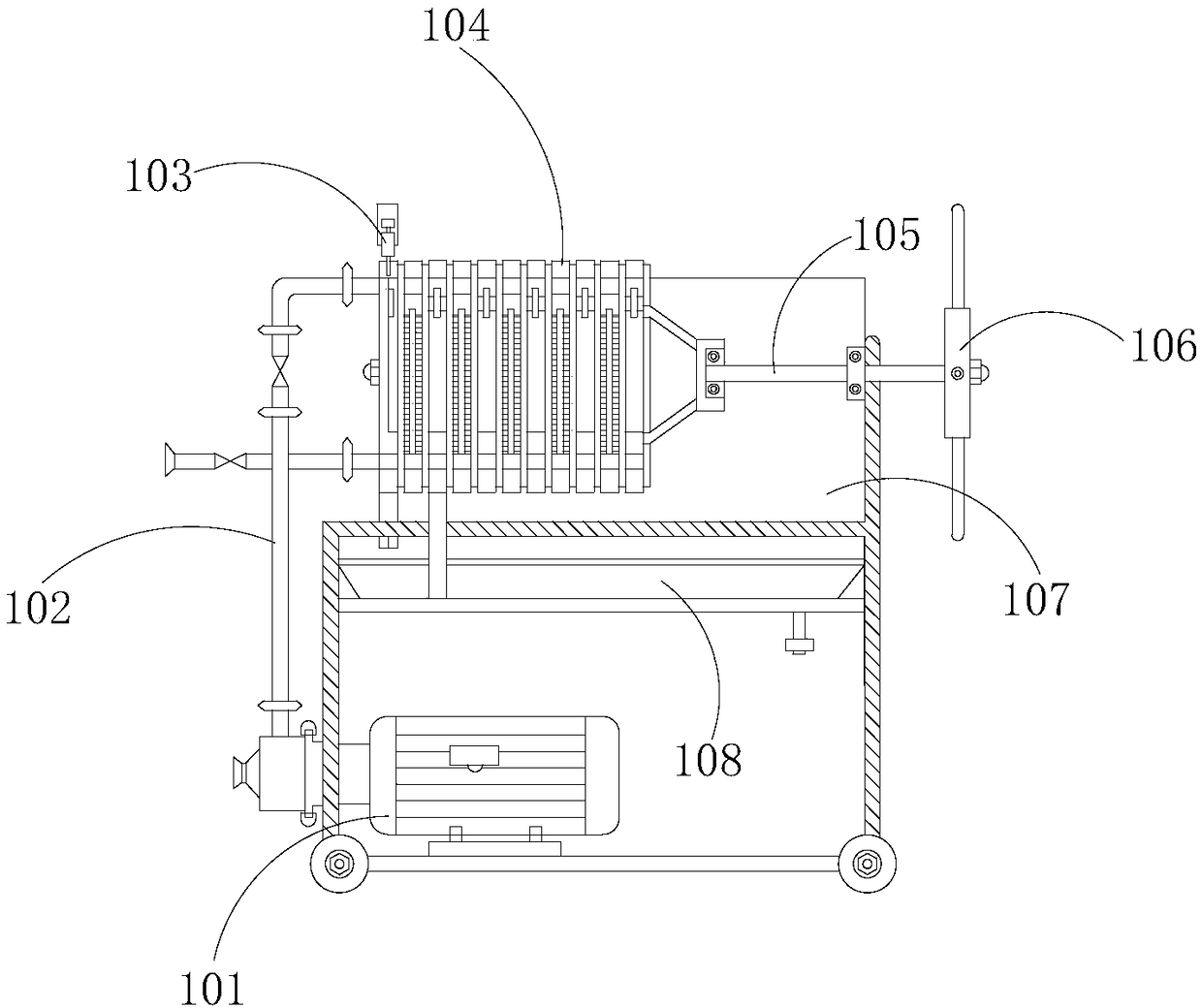

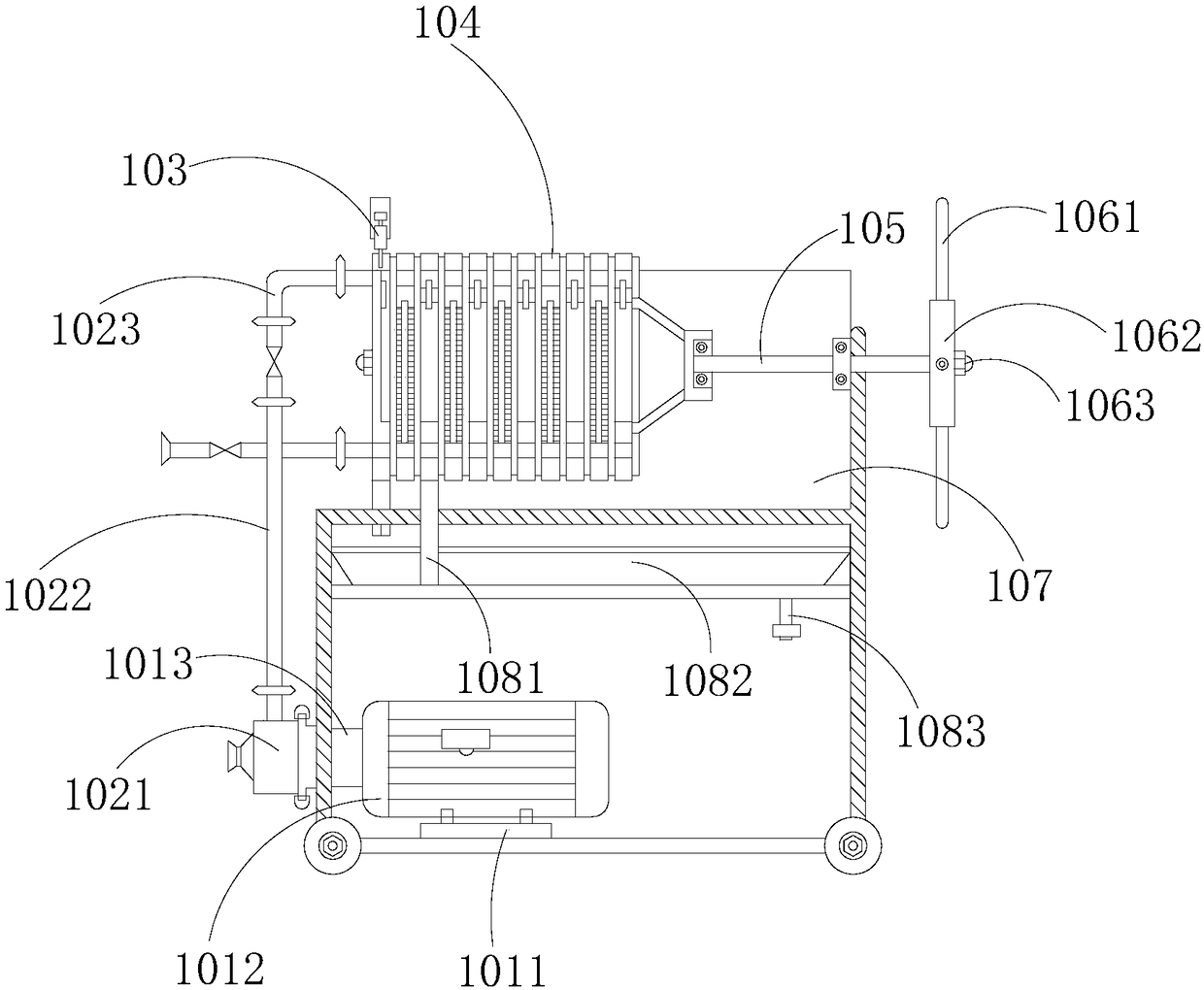

[0021] Such as Figure 1-Figure 5As shown, the present invention provides a waste liquid treatment device for hospital laboratory, its structure includes: waste liquid treatment mechanism 1, hydraulic power device 2, frequency conversion motor 3, fixed base plate 4, fixed frame 5, wheels 6, frequency conversion box 7 , a support rod 8, the waste liquid treatment mechanism 1 is vertically installed on the upper end of the fixed bottom plate 4 and has clearance fit with the fixed frame 5, the hydraulic power unit 2 is horizontally embedded in the left end of the waste liquid treatment mechanism 1 and is connected with the frequency conversion motor 3 Interference fit, the variable frequency motor 3 runs through the inside of the fixed frame 5 horizontally and is electrically connected to the hydraulic power unit 2, the fixed bottom plate 4 has a rectangular cross-section and is vertically installed on the lower end of the waste liquid treatment mechanism 1 and is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com