Flow mixing apparatus of viscous ammonium nitrate fuel oil explosives

A technology of ammonium explosives and air-flow mixing, which is applied to explosives, mixers, explosives processing equipment and other directions, can solve the problems affecting the quality of viscous ammonium explosives, uneven mixing, etc., and achieves simple structure, high production efficiency, high production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

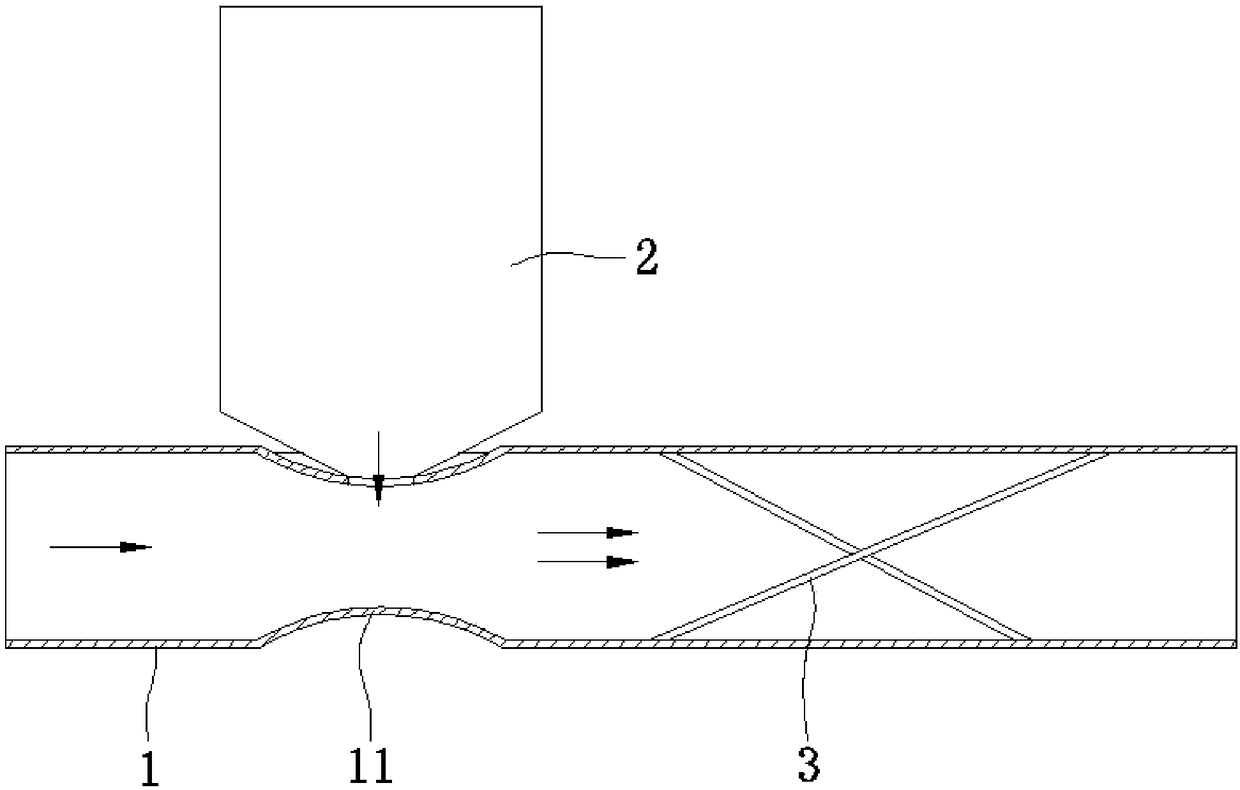

[0015] Such as figure 1 As shown, the mixing pipe 1 is preferably a straight-through circular pipe structure, and is preferably made of stainless steel. A diameter-reducing section 11 is formed by deformation at the front part of the mixing pipe 1. The diameter-reducing section 11 is of a rotary structure and symmetrical front and rear. The diameter of the diameter-reducing section 11 gradually decreases from front to back and then gradually increases. There is a blanking opening on the top of the smallest part of the shrinking section 11, and a rubber storage container 2 is arranged above the blanking opening. The bottom of the rubber storage container 2 is funnel-shaped. connected, and a valve is installed at the discharge port at the bottom of the glue storage container 2. The deflector 3 that makes the viscous ammonium oil explosives spirally conveyed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com