A kind of modified polyester material and preparation method thereof

A technology of modified polyester and impact modifier, which is applied in the field of polyester materials, can solve problems such as environmental hazards, oil stains on the surface of tableware are not easy to clean, and health effects, and achieve reliable hardness, good toughness, and impact resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

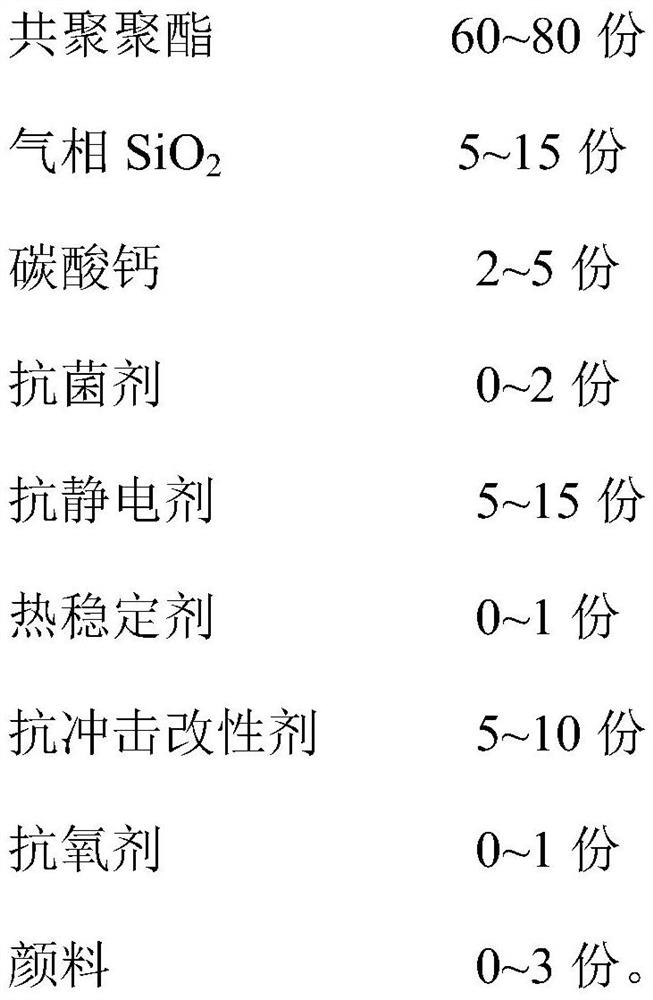

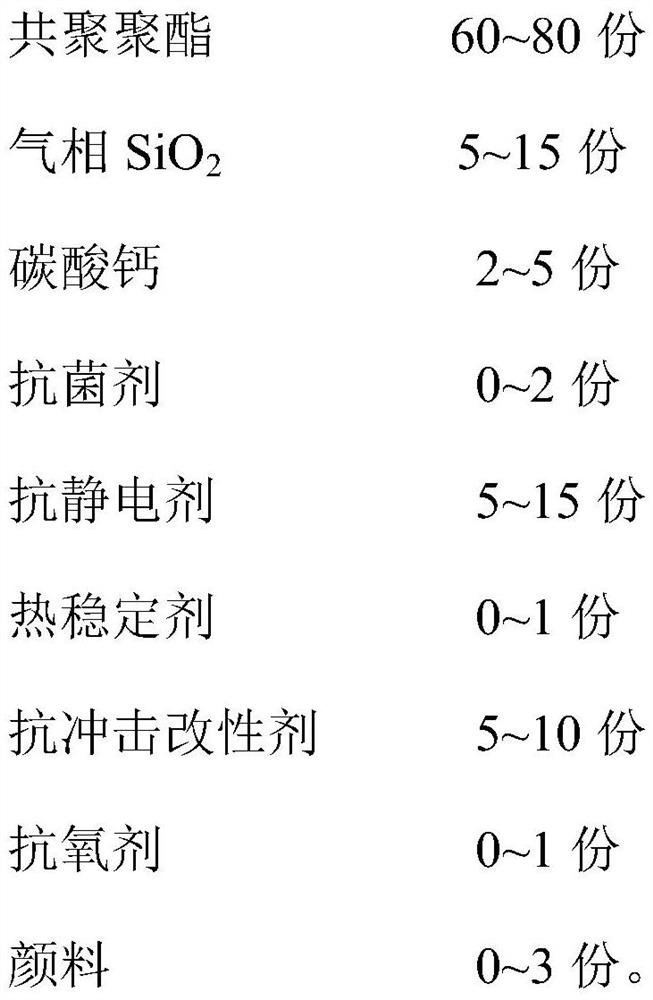

Method used

Image

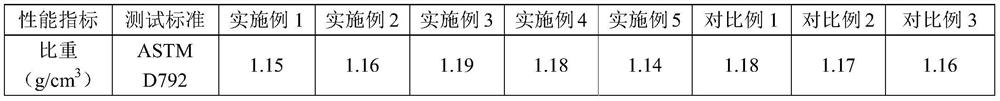

Examples

Embodiment 1

[0041] In parts by weight, weigh 65 parts of copolyester and 15 parts of gas-phase SiO 2 , 5 parts of calcium carbonate, 2 parts of silver ion activated carbon, 14 parts of ethoxylated lauric acid amine, 0.7 parts of vitamin C, 7 parts of thermoplastic elastomer, 1 part of 2,2'-methylene bis( 4-methyl-6-tert-butylphenol) and 2 parts of pigments are dried and placed in a mixer to stir and mix, and the mixed materials are added to a twin-screw extruder to melt and extrude, wherein, the dry The temperature is 100°C, and the drying time is 3 hours. The extrusion temperatures of the twin-screw extruder from the feed port to the extrusion die are: 240-280°C for the first stage, 240-280°C for the second stage, and 240-280°C for the third stage. ℃, the nozzle is 240-280 ℃, the mold is 40-65 ℃, the rotation speed of the screw is 40r / min, the extruded filaments are cooled and granulated to prepare the modified polyester material.

Embodiment 2

[0043] In parts by weight, weigh respectively 75 parts of copolyester, 6 parts of gas phase SiO 2 , 4 parts of calcium carbonate, 1.5 parts of a mixture of silver ion silicate and silver ion titanate, 11 parts of a mixture of ethoxylated ammonium laurate and dilauryl phosphate, and 0.8 parts of a mixture of bio-based epoxy oxide Soybean oil, a mixture of vitamin E, 6 parts of chlorinated polyethylene, ethylene-vinyl acetate copolymer, a mixture of styrene-butadiene-styrene copolymer, 0.2 parts of tris(2,4-di-tert-butylbenzene Base) phosphite and 1.5 parts of pigments, after drying, place them in a mixer to stir and mix, put the mixed materials into a twin-screw extruder to melt and extrude them, the drying temperature is 110 °C, and the drying time The extrusion temperature of the twin-screw extruder from the feed port to the extrusion die is: 240-280°C for the first stage, 240-280°C for the second stage, 240-280°C for the third stage, and 240-280°C for the nozzle , the mold ...

Embodiment 3

[0045] In parts by weight, weigh respectively 65 parts of copolyester, 12 parts of gas phase SiO 2 , 2 parts of calcium carbonate, 1 part of silver ion ceramic, 8 parts of a mixture of ethoxylated ammonium laurate, dilauryl phosphate and glycerol monostearate, 1 part of vitamin C, a mixture of vitamin E, 8 parts Parts of acrylonitrile-butadiene-styrene copolymer, a mixture of methyl methacrylate-butadiene-styrene copolymer, 1 part of 2,2'-methylenebis(4-methyl-6 - tert-butylphenol) and 1 part of pigment, after drying, place them in a mixer to stir and mix them, and put the mixed materials into a twin-screw extruder to melt and extrude them, wherein the drying temperature is 125°C, and the drying The extrusion time of the twin-screw extruder from the feed port to the extrusion die head is 4 hours, the extrusion temperature of the first stage is 240-280°C, the second stage is 240-280°C, the third stage is 240-280°C, and the nozzle is 240-280°C. ℃, the mold is 40-65 ℃, the rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com