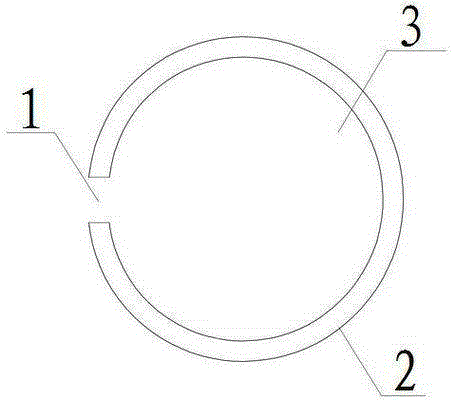

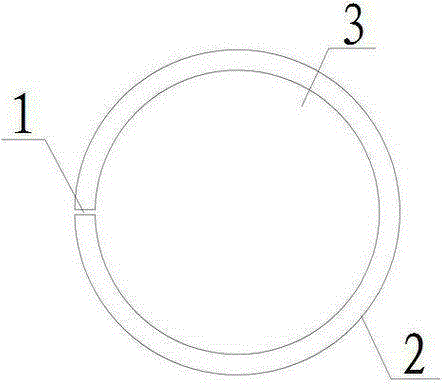

A novel high heat-resistant turbocharger sealing ring and its preparation method

A turbocharger and sealing ring technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of turbocharger oil leakage, low heat resistance temperature, and air leakage, so as to improve the competitiveness of enterprises, Good thermal stability and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A novel high heat-resistant turbocharger seal ring of the present invention, its chemical composition includes C, Mn, Si, Cr, Co, Al, Ti, Mo, P, S, Cu, Ni, B, Nb+Ta , Fe; the mass of the chemical components is C: 0.8kg, Mn: 0.35kg, Si: 0.35kg, Cr: 17.0kg, Co: 1.0kg, Al: 0.2kg, Ti: 0.65kg, Mo: 2.8kg, P: 0.015kg, S: 0.015kg, Cu: 0.3kg, Ni: 50.0kg, B: 0.002kg, Nb+Ta: 4.75kg, Fe: 21.768kg.

[0025] The preparation method of the above-mentioned novel high heat-resistant turbocharger sealing ring of the present embodiment comprises the following steps:

[0026] (1) According to the above chemical composition C, Mn, Si, Cr, Co, Al, Ti, Mo, P, S, Cu, Ni, B, Nb+Ta, Fe, purchase cast steel pig iron, ferrosilicon, ferrochrome , ferromolybdenum, ferromanganese, ferronickel, and ferro-titanium are cast into billets, and then the billets are sent into the combustion furnace to gradually raise the temperature (50°C per hour) to 715°C, and then uniformly cool down after 9.8 hours o...

Embodiment 2

[0032] A novel high heat-resistant turbocharger seal ring of the present invention, its chemical composition includes C, Mn, Si, Cr, Co, Al, Ti, Mo, P, S, Cu, Ni, B, Nb+Ta , Fe; the mass of the chemical components is C: 0.6kg, Mn: 0.3kg, Si: 0.3kg, Cr: 20.0kg, Co: 0.8kg, Al: 0.4kg, Ti: 1.0kg, Mo: 3.0kg, P: 0.01kg, S: 0.01kg, Cu: 0.2kg, Ni: 53.0kg, B: 0.004kg, Nb+Ta: 5.0kg, Fe: 15.376kg.

[0033] The preparation method of the above-mentioned novel high heat-resistant turbocharger sealing ring of the present embodiment comprises the following steps:

[0034] (1) According to the above chemical composition C, Mn, Si, Cr, Co, Al, Ti, Mo, P, S, Cu, Ni, B, Nb+Ta, Fe, purchase cast steel pig iron, ferrosilicon, ferrochrome , ferromolybdenum, ferromanganese, ferronickel, and ferro-titanium are cast into blanks, and then the blanks are sent into the combustion furnace to gradually increase the temperature (50°C per hour) to 720°C, and evenly cool down after 10 hours of heat preserv...

Embodiment 3

[0040] A novel high heat-resistant turbocharger seal ring of the present invention, its chemical composition includes C, Mn, Si, Cr, Co, Al, Ti, Mo, P, S, Cu, Ni, B, Nb+Ta , Fe; the mass of the chemical components is C: 0.4kg, Mn: 0.2kg, Si: 0.2kg, Cr: 21.0kg, Co: 0.6kg, Al: 0.8kg, Ti: 1.15kg, Mo: 3.3kg, P: 0.015kg, S: 0.015kg, Cu: 0.3kg, Ni: 55.0kg, B: 0.006kg, Nb+Ta: 5.5kg, Fe: 11.514kg.

[0041] The preparation method of the above-mentioned novel high heat-resistant turbocharger sealing ring of the present embodiment comprises the following steps:

[0042] (1) According to the above chemical composition C, Mn, Si, Cr, Co, Al, Ti, Mo, P, S, Cu, Ni, B, Nb+Ta, Fe, purchase cast steel pig iron, ferrosilicon, ferrochrome , ferromolybdenum, ferromanganese, ferronickel, and ferro-titanium are cast into billets, and then the billets are sent into the combustion furnace to gradually increase the temperature (50°C per hour) to 725°C, and then uniformly cool down after 10.2 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com