Contact element for electrically interconnecting electrical conductor and connection part of electrical system, and method for producing same

A technology for electrical equipment and contact elements, which is applied in the direction of electrical components, conductive connections, electrical component connections, etc., and can solve problems such as reliable sealing is not optimal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

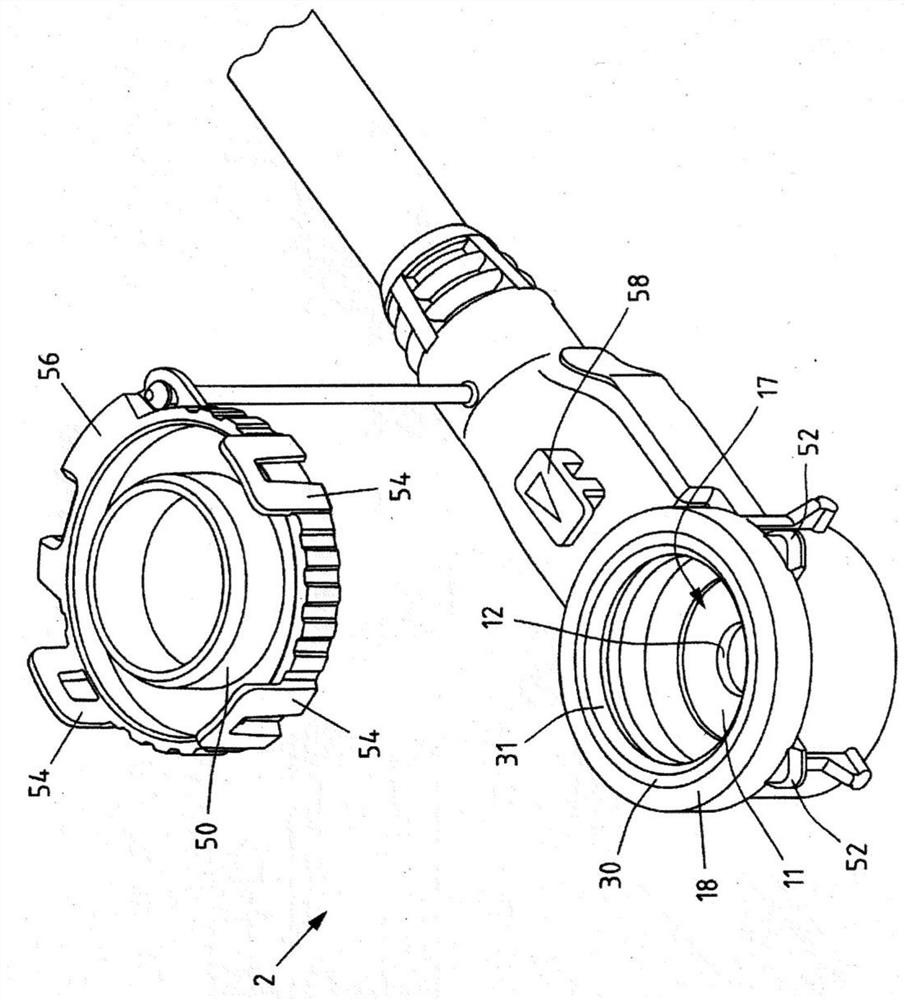

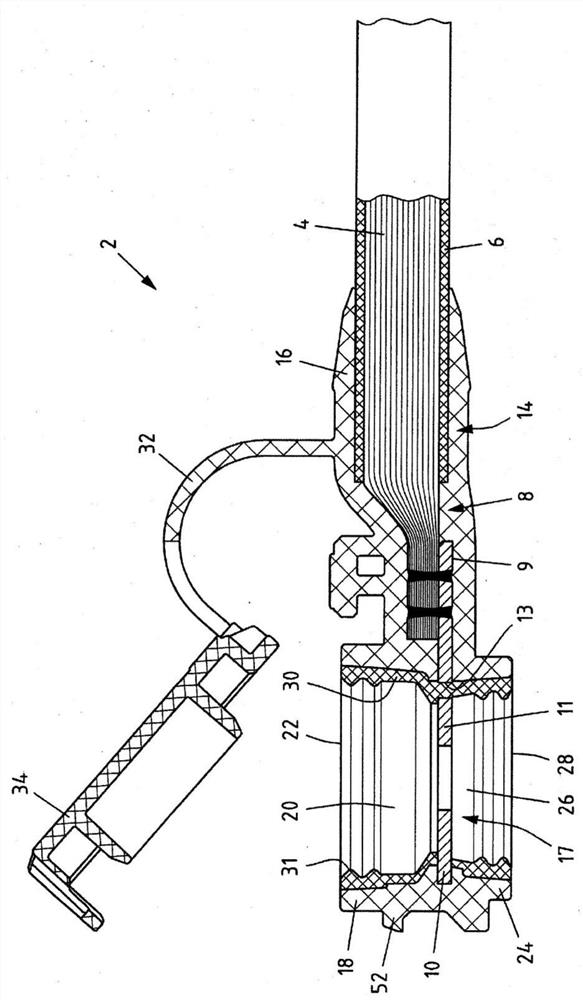

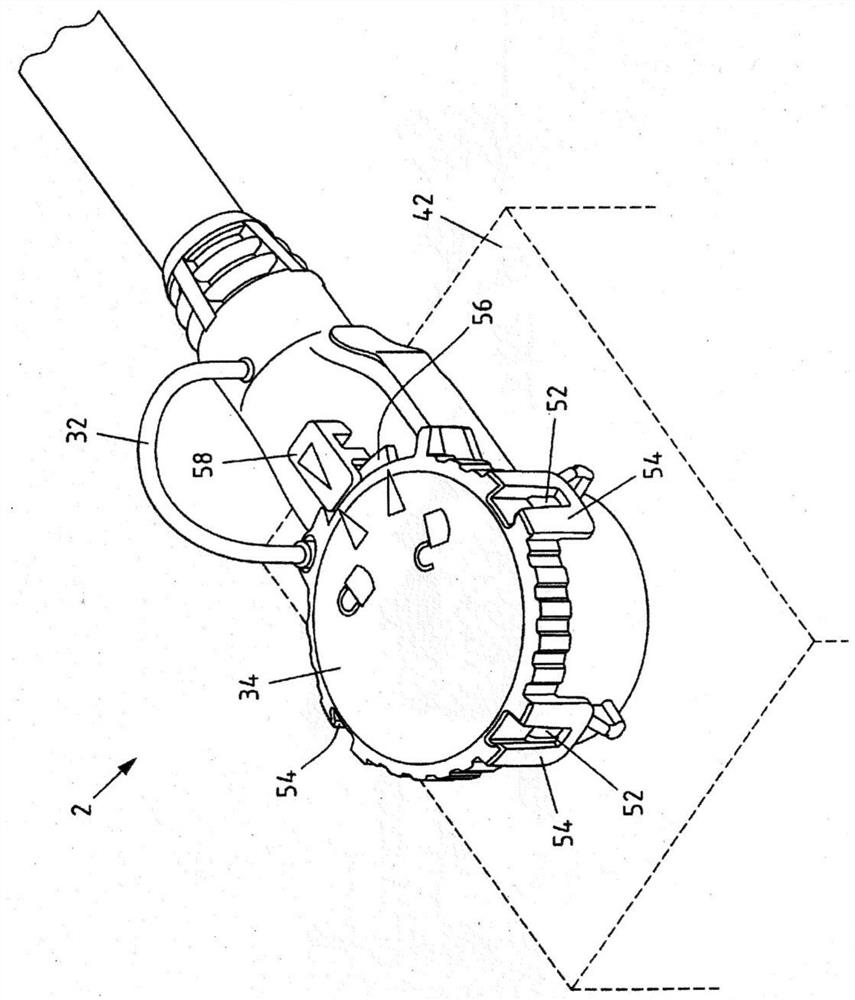

[0045] Figure 1a-Figure 1b In isometric diagram ( Figure 1a ) and cross-sectional view (Figure lb) shows an embodiment of the contact element.

[0046] The contact element 2 comprises an electrical conductor 4 which is sheathed with a conductor insulation 6 of relatively soft polyurethane having a Shore A hardness of 80. The end 8 of the conductor 4 is stripped of the insulation and welded by means of ultrasonic waves (in Figure 1b ) is connected in an electrically conductive manner to the connection region 9 of the cable gland 10 . The cable gland 10 has a flat ring-shaped contact piece 11 with a central hole 12 and a plurality of smaller openings 13 arranged around it.

[0047] The cable connection 10 and the section 14 of the electrical conductor 4 connected thereto are injection-moulded with an electrically insulating jacket 16 made of polyurethane, the part 17 of the contact piece 11 having the hole 12 being exposed.

[0048] The housing 16 forms a first socket 18 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com