Double-layer flashy fabric with 20D black nylon yarns

A fabric and nylon technology, applied in textiles, fabrics, multi-strand fabrics, etc., can solve the problems of clothing wrinkling, slip dislocation, different shrinkage rates of fabrics, etc., and achieve easy care, good tissue density, and excellent softness. sense of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

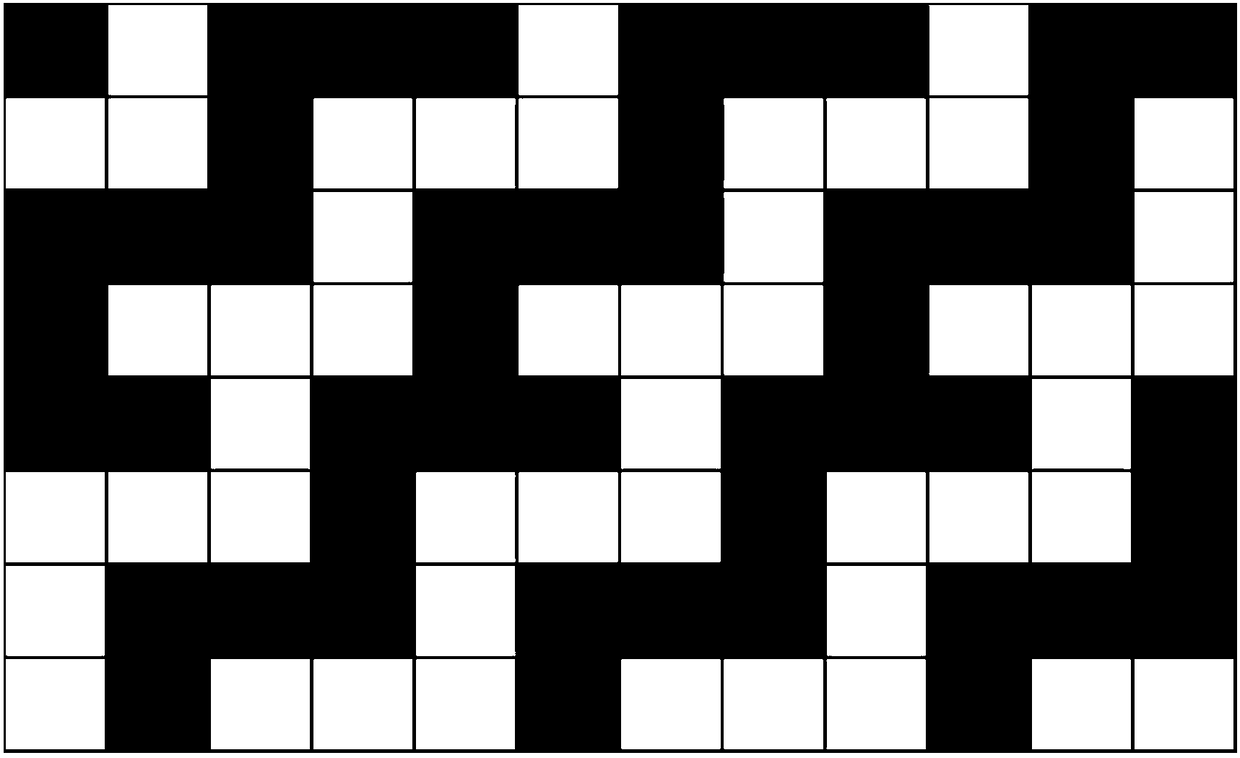

Image

Examples

Embodiment

[0021] combine figure 1 , the invention discloses a 20D nylon black silk double-layer flash fabric, including a fabric body; the fabric body is woven with a basic plain double-layer weave structure from warp threads and weft threads, and adopts infinitely variable stripe channel spacing; the weft threads Including the first weft and the second weft; the fabric body includes the first layer of fabric composed of the warp and the first weft, and the second layer of fabric composed of the warp and the second weft; The warp yarn is 20D / 24F nylon FDY BR processed yarn; the first weft yarn is 20D / 24F nylon black FDY BL processed yarn, and the second weft yarn is 20D / 24F nylon FDY BR processed yarn.

[0022] Specifically, the stripe channel is a regular channel, a gradual channel or a channel with a variable pitch; the distance between the stripe channels is 3cm-15cm. The warp and weft density of the fabric body is 180 threads / cm×157 threads / cm. The fabric body is 12 healds. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com