Foundation-pit-free pilot-tunnel-free self-balancing pipeline excavation method and device

A self-balancing, pipeline technology, applied in pipeline laying and maintenance, tunnels, earthwork drilling and mining, etc., can solve problems such as environmental pollution, traffic jams, and damage to infrastructure, and achieve the effect of convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

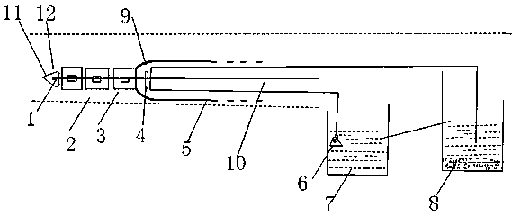

[0021] Embodiment 1. This embodiment provides a self-balancing pipe excavation method without foundation pit and pilot hole, including the following steps: (1) The front cutter head 1 and the back cutter head 2 arranged in pairs and rotating in opposite directions are cut by the driving module Provide thrust; (2) balance the sensor 4 in the process of advancing the state of the sensing device, and the controller will control the start and stop of the front and rear cutter head 2 switches to maintain the self-balanced state of the device; (3) turn on The excavated soil is impacted by the water flow and the muddy water is output through the pipe of the hose 5; (4) The drill bit and drive module pull the hose to the target position; (5) Remove the drill bit and drive module, and then clean the pipe to complete the entire construction process. Among them, the rear of the front cutter head 1 and the rear cutter head 2 are also matched with a spiral friction drive block 3, there are ...

Embodiment 2

[0022] Embodiment 2. This embodiment provides a device for a self-balancing pipe excavation method without foundation pits and pilot holes. The device includes a device body. The device body includes a bracket, a cutting part and a driving part. The cutting part includes a pair of front cutter heads 1, For the rear cutter head 2, the driving part includes a spiral friction driving block 3. The device body also includes a balance sensor 4 arranged on the support and sensing the balance state of the device, and a controller that controls the switching of the cutting part and the driving part. In addition, a guide device 11 is arranged at the front of the front cutter head 1, and the position and direction signal of the drill bit is transmitted to the video detector on the ground through the guide device 11 to realize manual adjustment control. There is a hose 5 at the rear of the support. The outermost part of the hose 5 is provided with a sedimentation tank 8 and a clear water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com