A fully variable valve train driven by hydraulic pressure

A valve train, variable technology, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., can solve the problem of small adjustment range, the valve cannot meet the needs of intake, and the valve lift cannot be changed independently and other problems, to achieve the effect of wide adjustment range, improved inflation efficiency, and simple oil circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

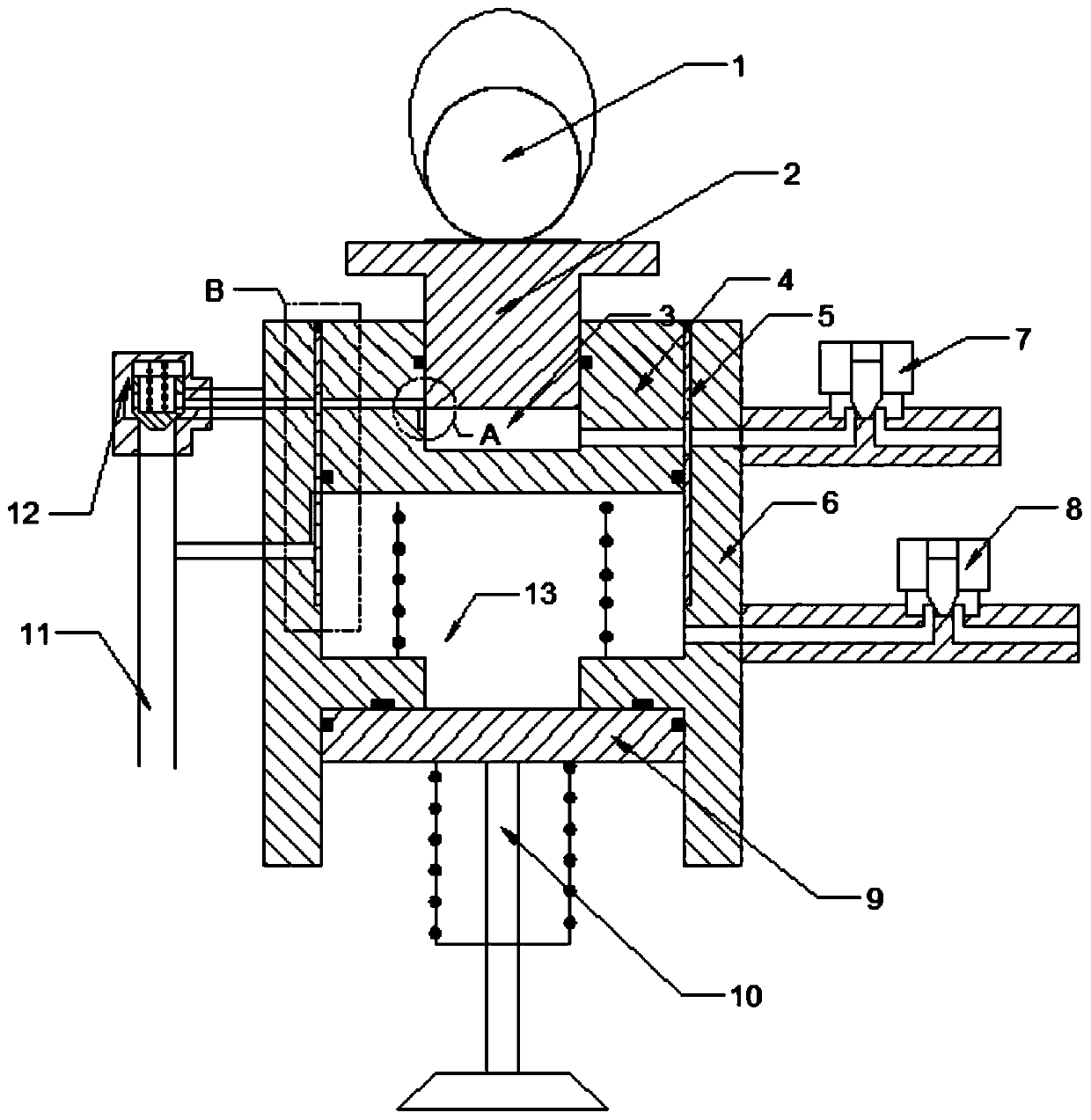

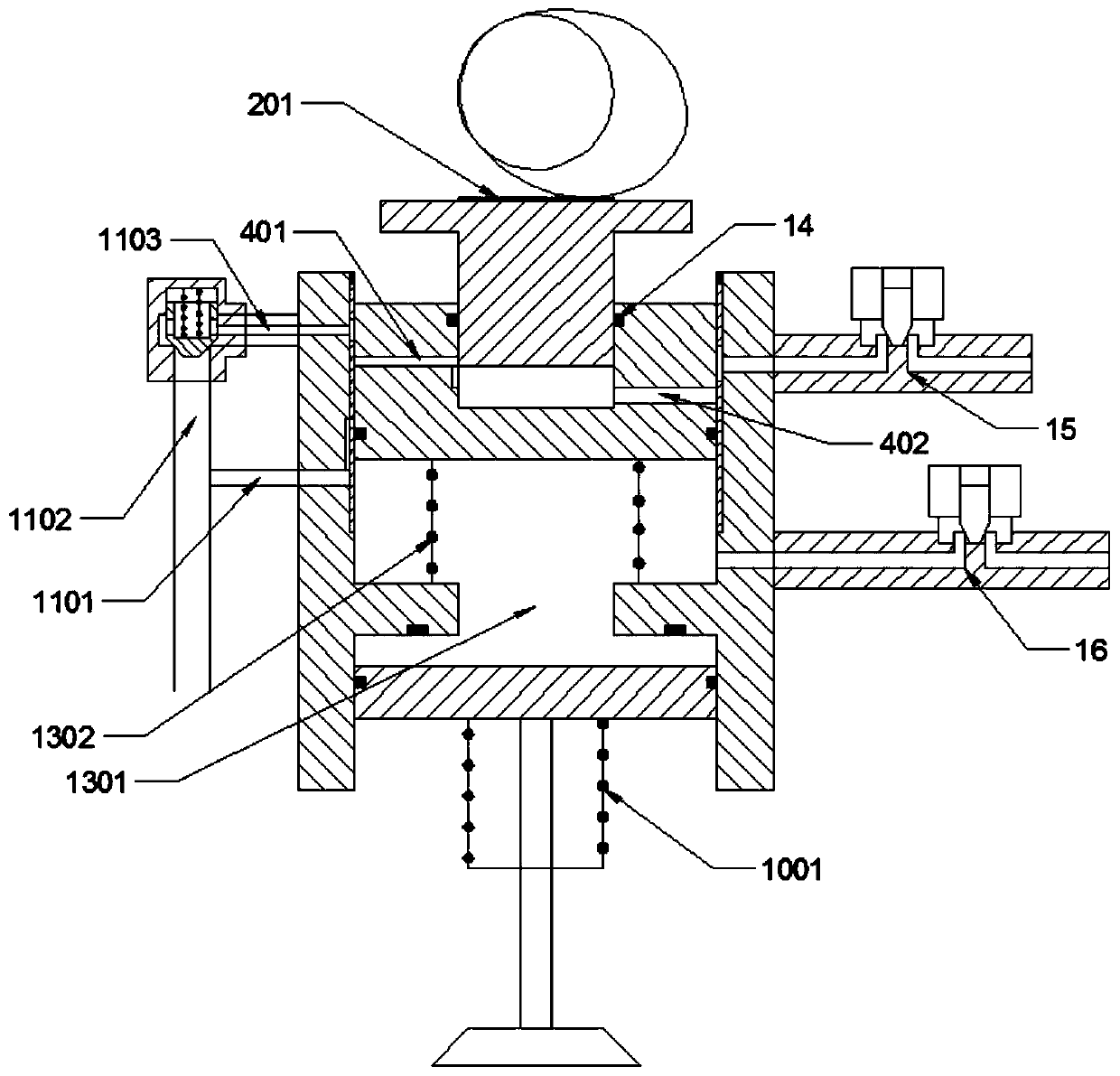

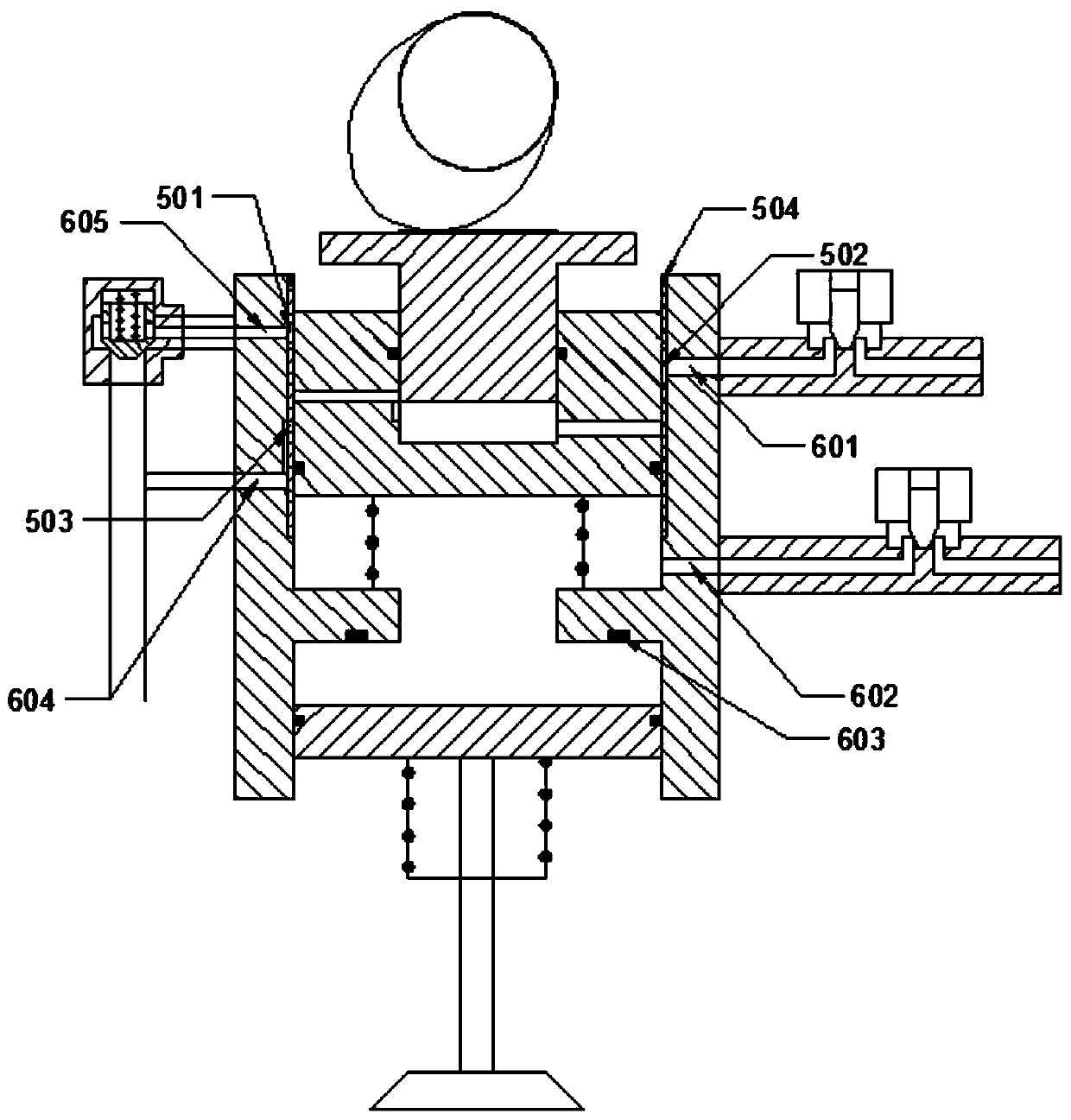

[0036] Such as figure 1 As shown, the hydraulically driven fully variable valve mechanism of the present invention includes a cam 1, a moving boss 2, a hydraulic piston 4, a bushing 5, a housing 6, a second solenoid valve oil unloading assembly 8, a hydraulic Plunger 9, valve 10, high pressure oil source 11 and one-way valve 12.

[0037] Specifically, the shell 6 is provided with a first hole, a second hole, and a third hole that are connected in sequence. The second hole 1301 in the middle has a smaller diameter than the other two through holes. The hydraulic piston 4 and the hydraulic column The plugs 9 are all cylindrical, the inner wall of the first hole is provided with a bushing 5, the hydraulic piston 4 and the bushing 5 are sliding and sealingly fitted, and the hydraulic plunger 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com