Oil way structure of cylinder block engine

A technology of cylinder block and oil circuit, applied in the direction of cylinder, cylinder head, mechanical equipment, etc., can solve the problems of many engine through pipelines, high engine cost, large size of the whole machine, etc. High matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

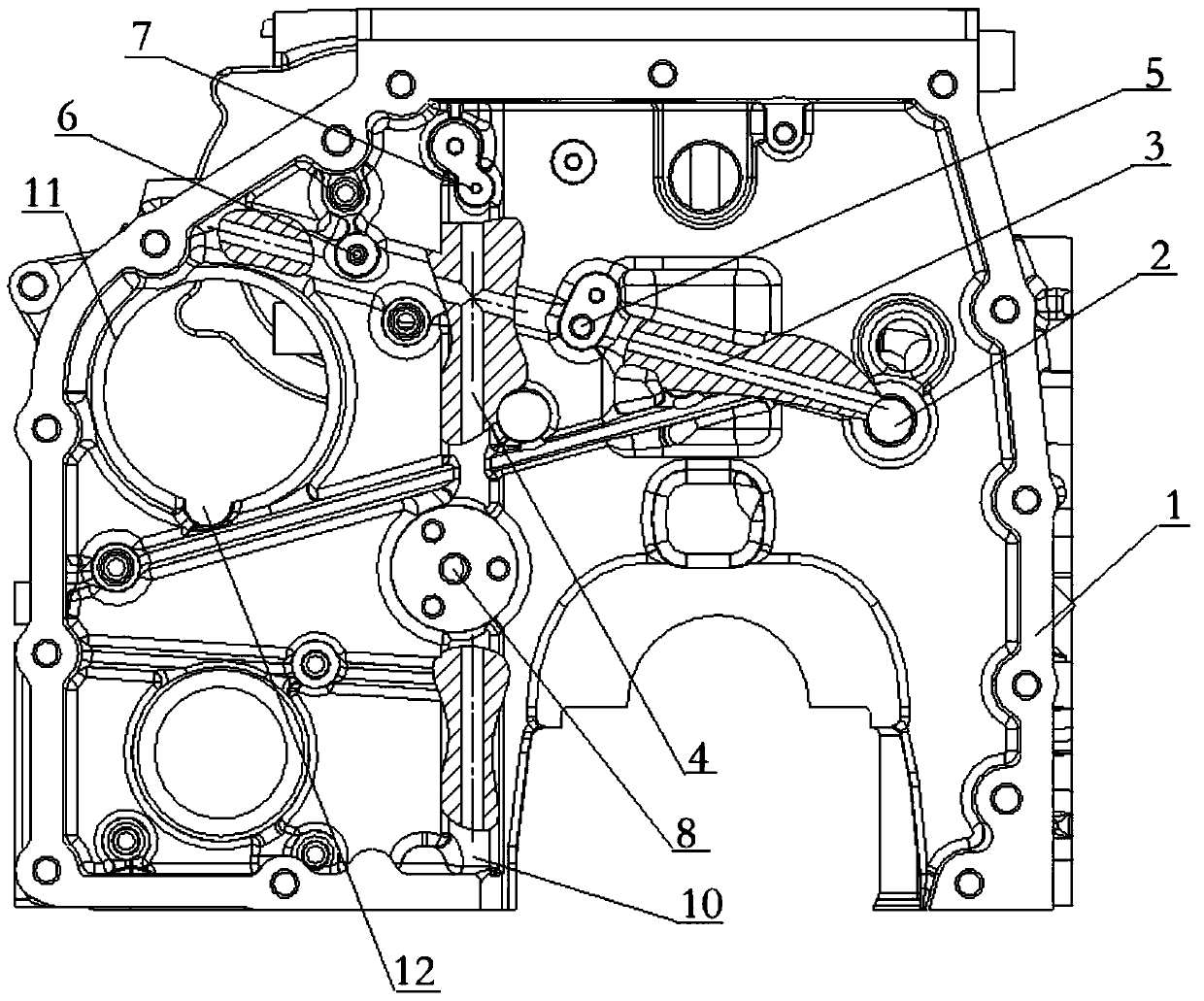

[0028] See also figure 1 and figure 2 , The embodiment of the present invention provides a cylinder block engine oil passage structure, including a main oil passage 2 arranged on the exhaust side of the engine and passing through the front and rear ends of the cylinder block 1 . The present invention also includes a transverse oil passage 3 and a longitudinal oil passage 4 arranged inside the gear chamber at the rear end of the cylinder block 1 . The right end of the horizontal oil passage 3 communicates with the main oil passage 2, and the left end spans the bottom of the gear chamber and communicates with the oil port 5 of the chain lubricating injection valve and the oil port 6 of the air pump respectively. The longitudinal oil passage 4 runs through the transverse oil passage 3, and the longitudinal oil passage 4 communicates with the oil port 7 of the chain tensioner and the lubricating oil port 8 of the idler shaft respectively.

[0029] When the oil passage structure...

Embodiment 2

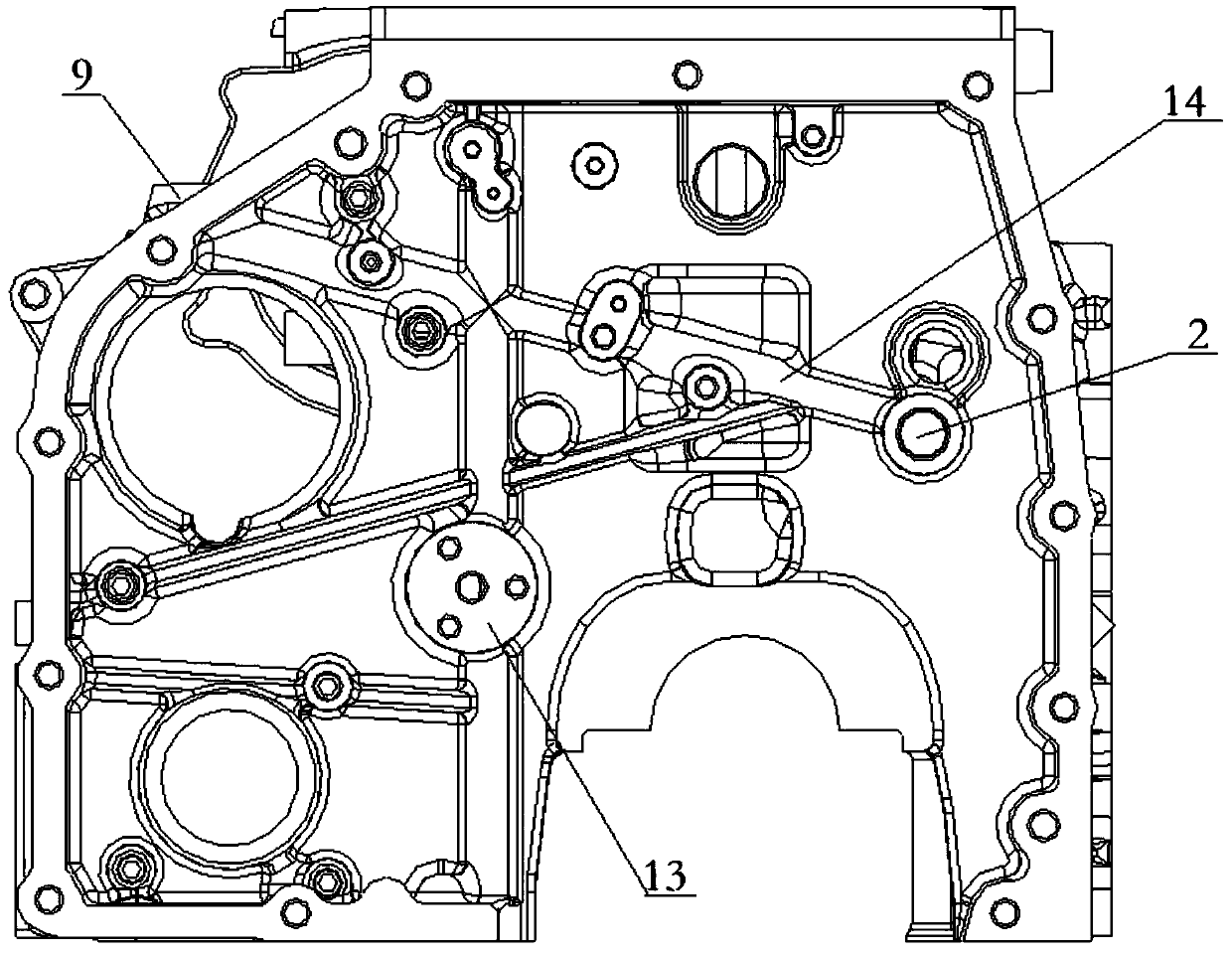

[0036] In this embodiment, except that the installation positions of the lubricating oil port of the air pump and the oil port of the chain tensioner are different, everything else is the same as that of Embodiment 1.

[0037] In this embodiment, the installation positions of the lubricating oil port of the air pump and the oil port of the chain tensioner are reversed. Specifically, one end of the horizontal oil passage is connected to the main oil passage, and the other end spans the bottom of the gear chamber and is respectively connected to the oil port of the chain lubricating injection valve and the oil port of the chain tensioner. The longitudinal oil passage runs through the transverse oil passage, and the longitudinal oil passage is respectively connected to the lubricating oil port of the air pump and the lubricating oil port of the idler shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com