A flexible connection rock splitting rod

A flexible connection and splitting rod technology, used in earth-moving drilling, servo meter circuits, mechanical equipment, etc., can solve the problems of splitting rod deformation and damage, splitting rod bending damage, increased construction costs, etc., to solve the problem of splitting The effect of stress concentration of crack rod, reduction of rock opening size, and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

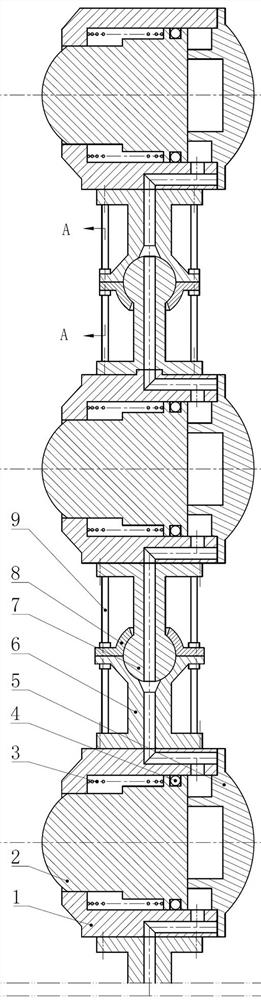

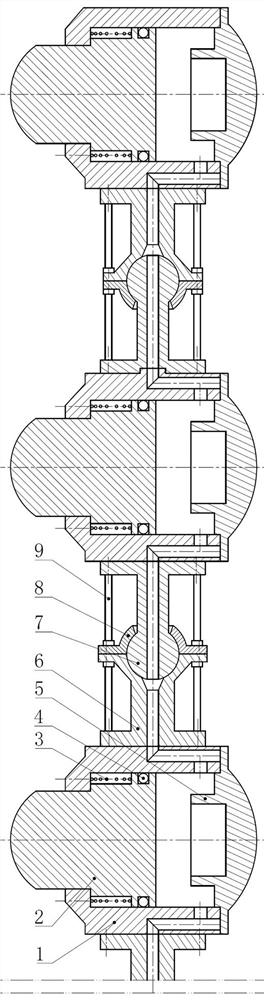

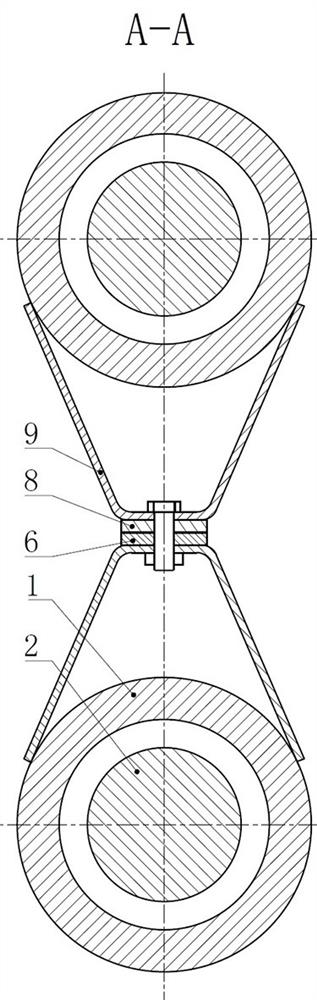

[0021] The present invention is not limited by the following examples, and specific embodiments can be determined according to the technical solutions and actual conditions of the present invention. The present invention will be described below with reference to the accompanying drawings. The positional relationship of up, down, left, right, etc. is based on the instructions attached. figure 1 The layout direction is determined.

[0022] The oil cylinder includes a cylinder block 1 , a piston 2 and a cylinder cover 5 . The cylinder block 1 is cylindrical as a whole. A piston 2 is installed in the cylinder block 1 , and a cylinder cover 5 is installed at the end of the cylinder block 1 . The piston 2 is a stepped shaft as a whole, the large end of the piston 2 is arranged in the cylinder 1 and a sealing ring 4 is arranged between the piston 2 and the cylinder 1 , and the small end of the piston 2 extends out of the cylinder 1 . The cylinder block 1 is provided with a cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com