Generator hydrogen cooler leakage detection method

A technology of coolers and generators, which is applied to the testing of machines/structural components. By detecting the appearance of fluid at the leak point, the direction of the instrument, etc., it can solve the problems of low leak detection efficiency, fast leakage, and many bolts. The leakage method is accurate and intuitive, saving maintenance costs and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

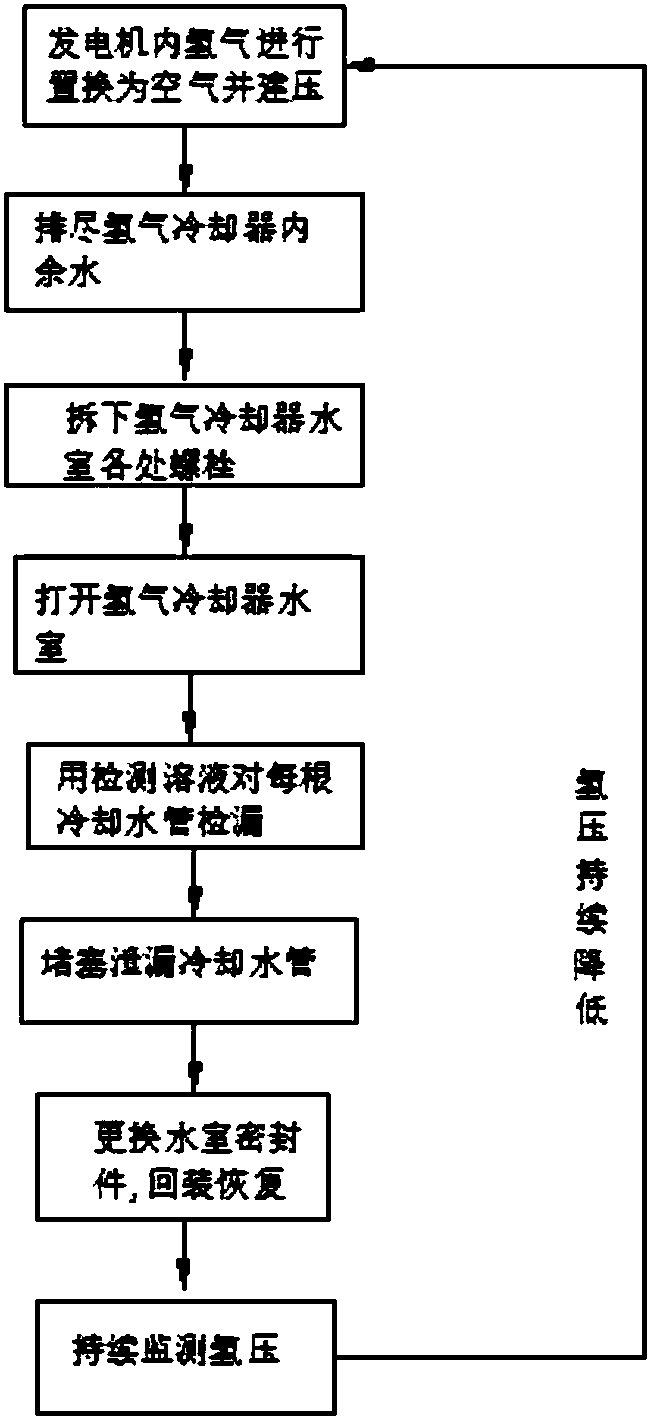

[0030] refer to figure 1 The method for leak detection of the generator hydrogen cooler shown includes the following steps,

[0031] S1: Measure the hydrogen pressure of the hydrogen in the hydrogen cooler several times, and replace the hydrogen in the hydrogen cooler with air after the hydrogen cooling generator is shut down;

[0032] S2: Close the water inlet door of the hydrogen cooler, open the water return door of the hydrogen cooler, and drain the remaining water inside the hydrogen cooler;

[0033] S3: Open the cover plate of the water chamber of the hydrogen cooler, and the cleaning device cleans the dirt inside the water chamber of the hydrogen cooler. The cleaning device includes a steel wire with a curved structure at the front end. The length of the curved part of the steel wire is 1-2cm, and the curved arc of the steel wire 30°-60°, the bending part of the steel wire is bound with non-woven fabric;

[0034] S4: Inject air into the generator stator chamber to inc...

Embodiment 2

[0039] A method for leak detection of a generator hydrogen cooler, comprising the following steps,

[0040] S1: Measure the hydrogen pressure of the hydrogen in the hydrogen cooler several times, and replace the hydrogen in the hydrogen cooler with air after the hydrogen cooling generator is shut down;

[0041] S2: Close the water inlet door of the hydrogen cooler, open the water return door of the hydrogen cooler, and drain the remaining water inside the hydrogen cooler;

[0042] S3: Open the cover plate of the water chamber of the hydrogen cooler, and the cleaning device cleans the dirt inside the water chamber of the hydrogen cooler. The cleaning device includes a steel wire with a curved structure at the front end. The length of the curved part of the steel wire is 1-2cm, and the curved arc of the steel wire 30°-60°, the bending part of the steel wire is bound with non-woven fabric;

[0043] S4: Inject air into the generator stator chamber to increase the air pressure in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com