Non-contact electromagnetic ultrasonic energy transducer capable of generating torsion guide wave and detection method thereof

A non-contact, electromagnetic ultrasonic technology, applied in the generation of ultrasonic/sonic/infrasonic waves, instruments, analysis materials, etc., can solve the problem that the magnetic conductivity of the measured material cannot be changed, and achieve simple structure, high signal-to-noise ratio, The effect of increasing the stimulus signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

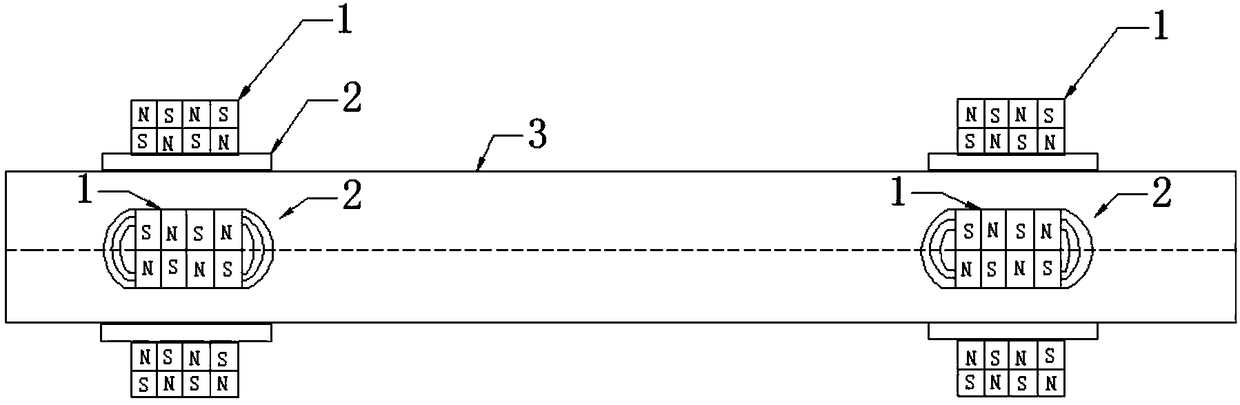

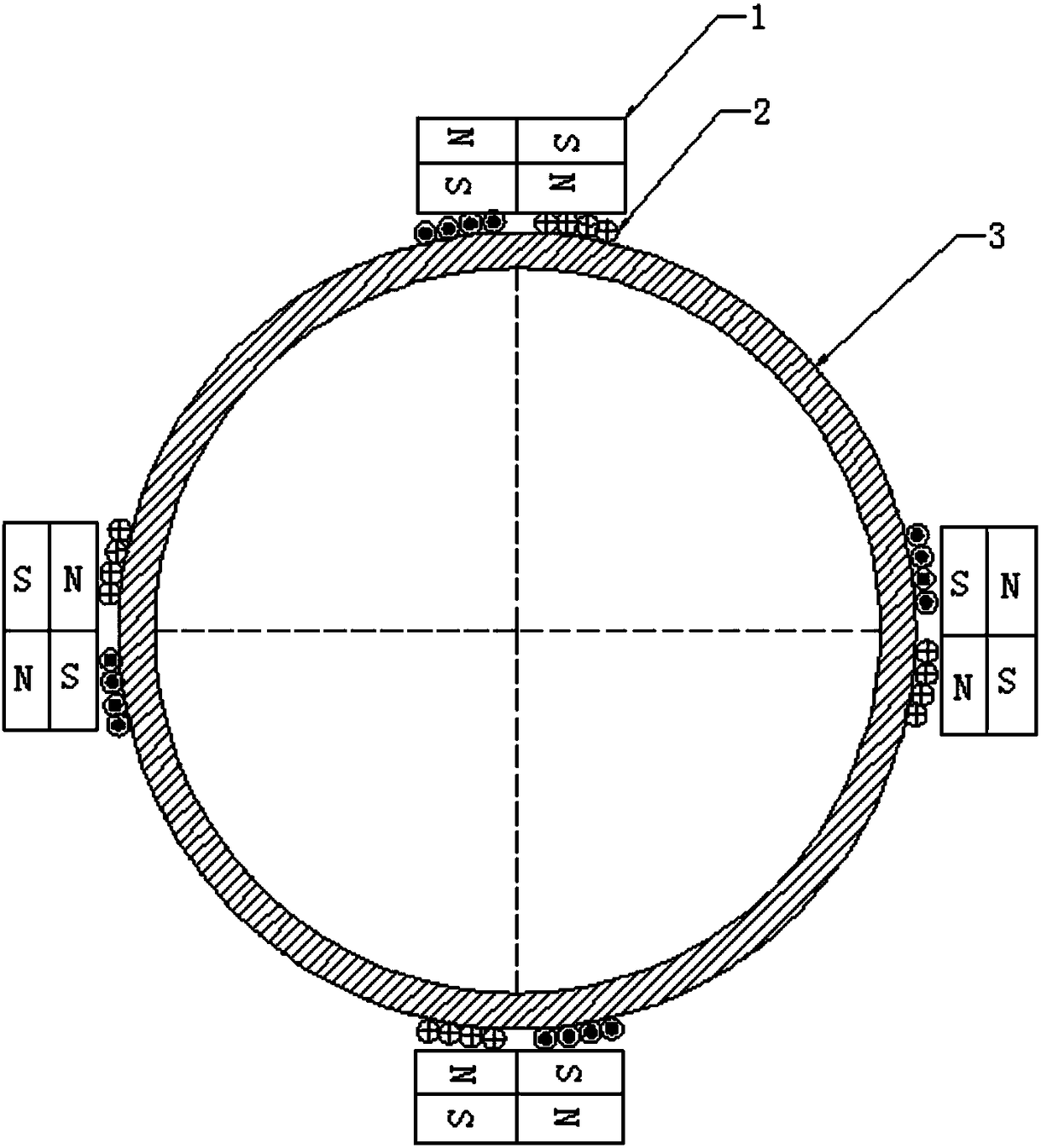

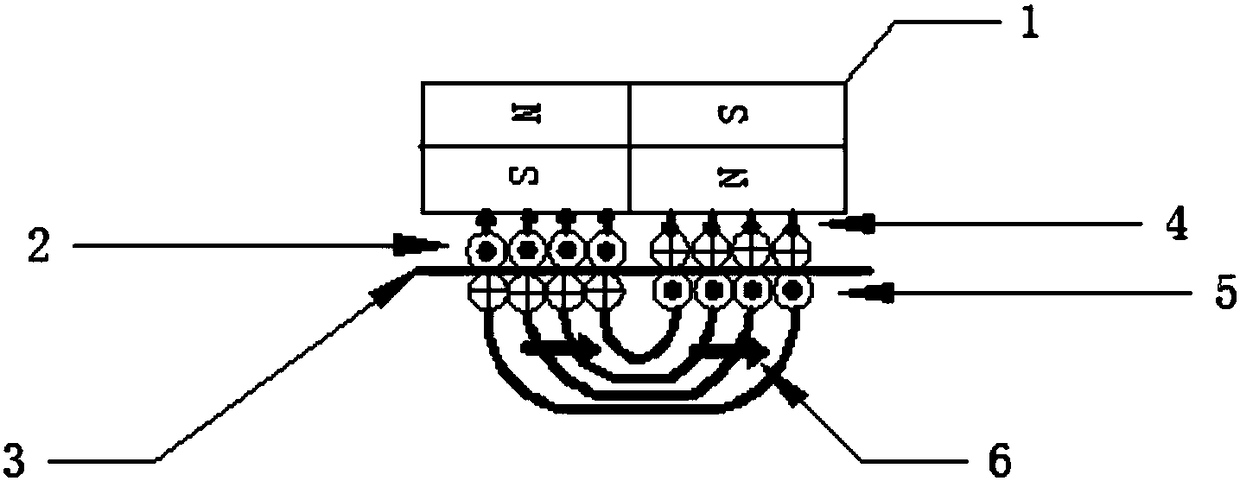

[0032] Figure 1-Figure 4 Shown is an embodiment of the non-contact electromagnetic ultrasonic transducer capable of generating torsional guided waves according to the present invention. The torsional guided wave electromagnetic ultrasonic transducer includes a permanent magnet 1 , a coil 2 and a steel pipe 3 to be tested.

[0033] The core component of the transducer is a racetrack-shaped coil 2. The coil 2 is in the shape of a racetrack, with 50 turns, 22mm inside and 69mm outside. The linear part of the coil is 40mm long and 23.5mm wide. Such a structure It can not only ensure the length of the linearly arranged part in the coil, but also reduce the length of the bending invalid part, which is beneficial to increase the eddy current density, thereby enhancing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com