Clamping device for testing equipment

A technology for testing equipment and clamping devices, which is applied in the direction of measuring devices, measuring device casings, electronic circuit testing, etc., can solve the problems of complex structure, high manufacturing cost, and small clamping force of manipulators, and achieve flexible rotation process and simplified structure , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

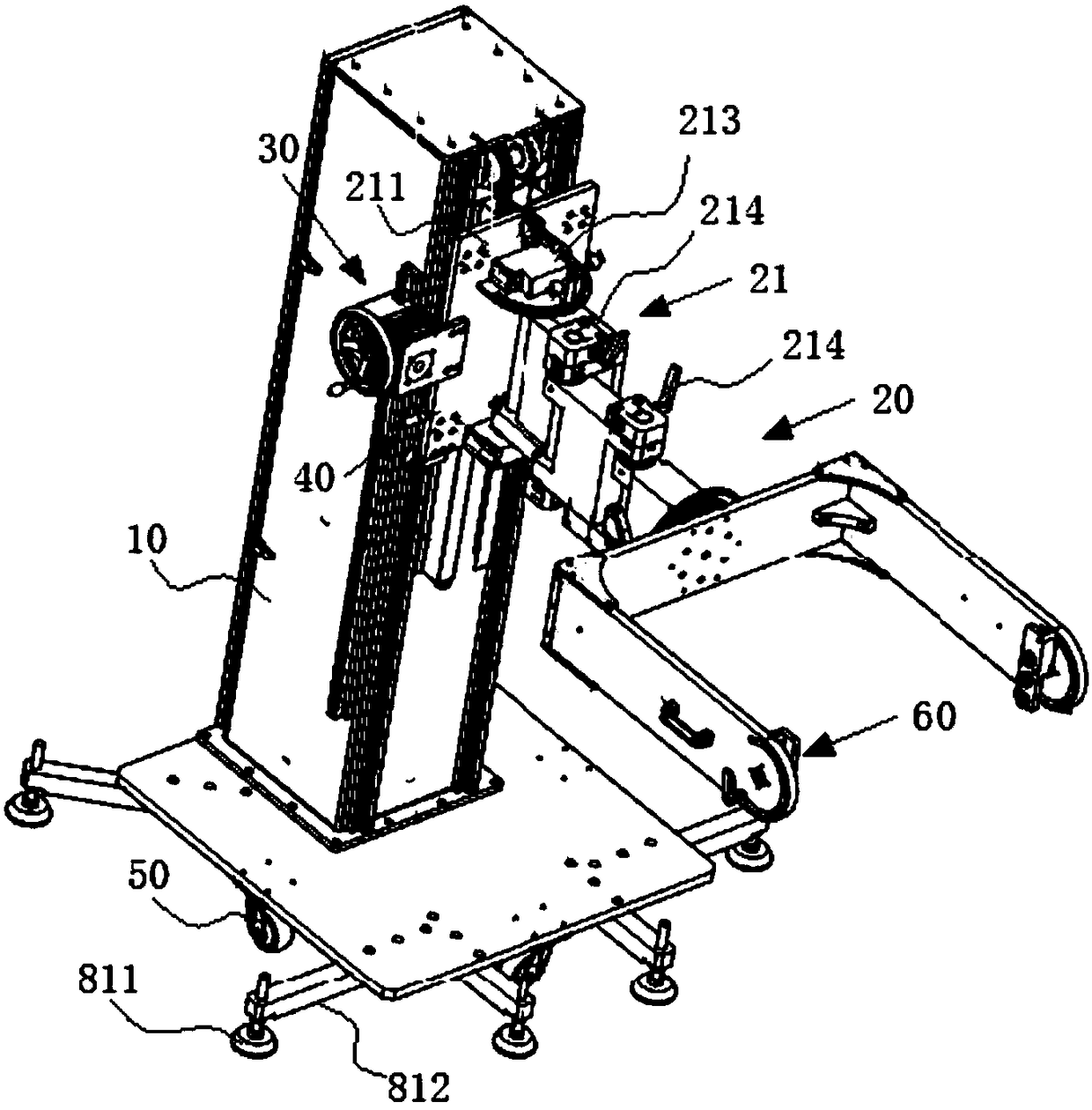

[0037] Embodiment: a kind of clamping device for testing equipment, such as Figure 1 to Figure 8 As shown, it includes a frame 10, a manipulator 20 installed on the frame, and a hand wheel deceleration structure 30 and a sliding structure 40 that drive the manipulator up and down; the hand wheel deceleration structure and the sliding structure are all installed on the machine. frame, and the manipulator is driven to translate up and down along the frame through the sliding structure through the hand wheel deceleration structure;

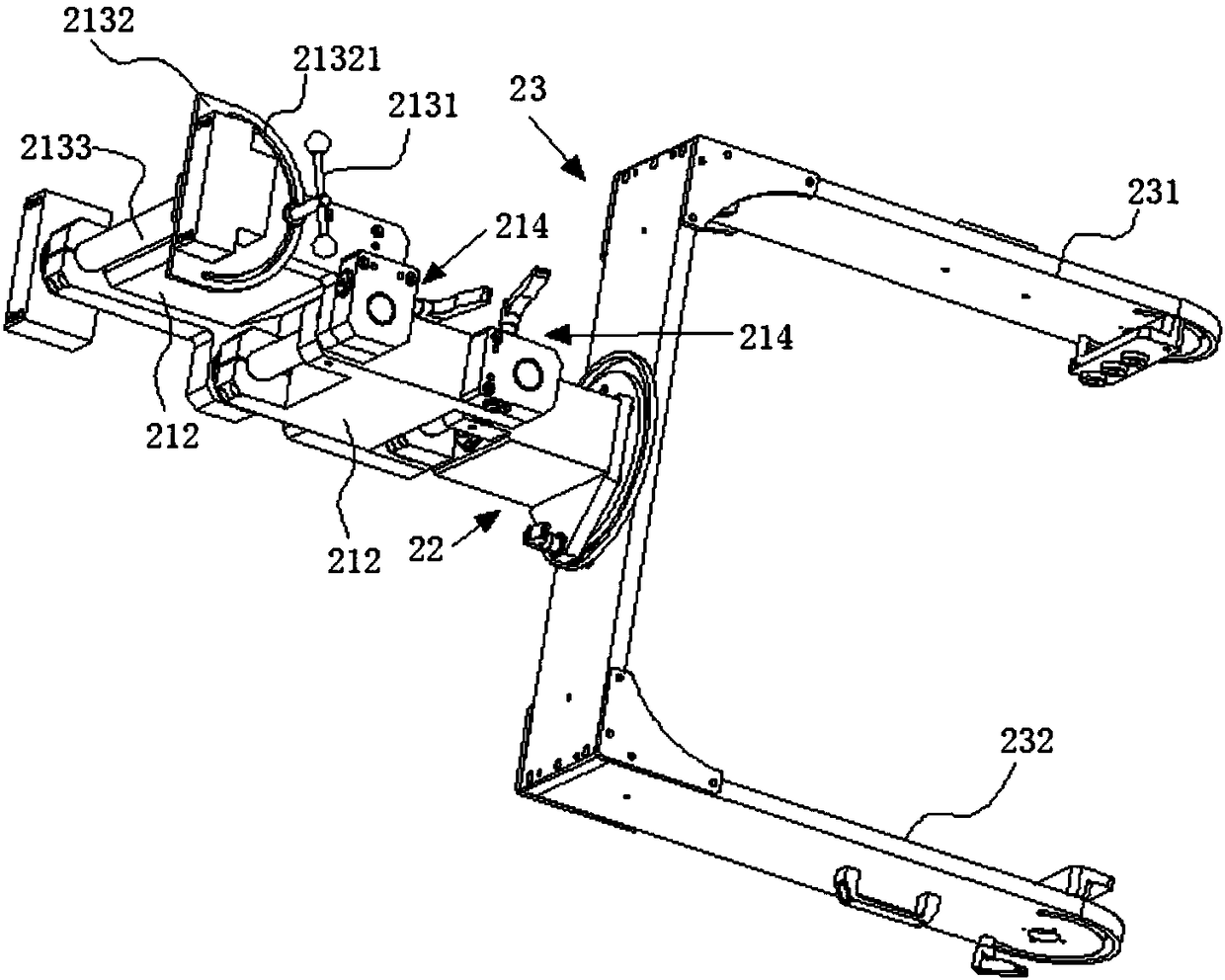

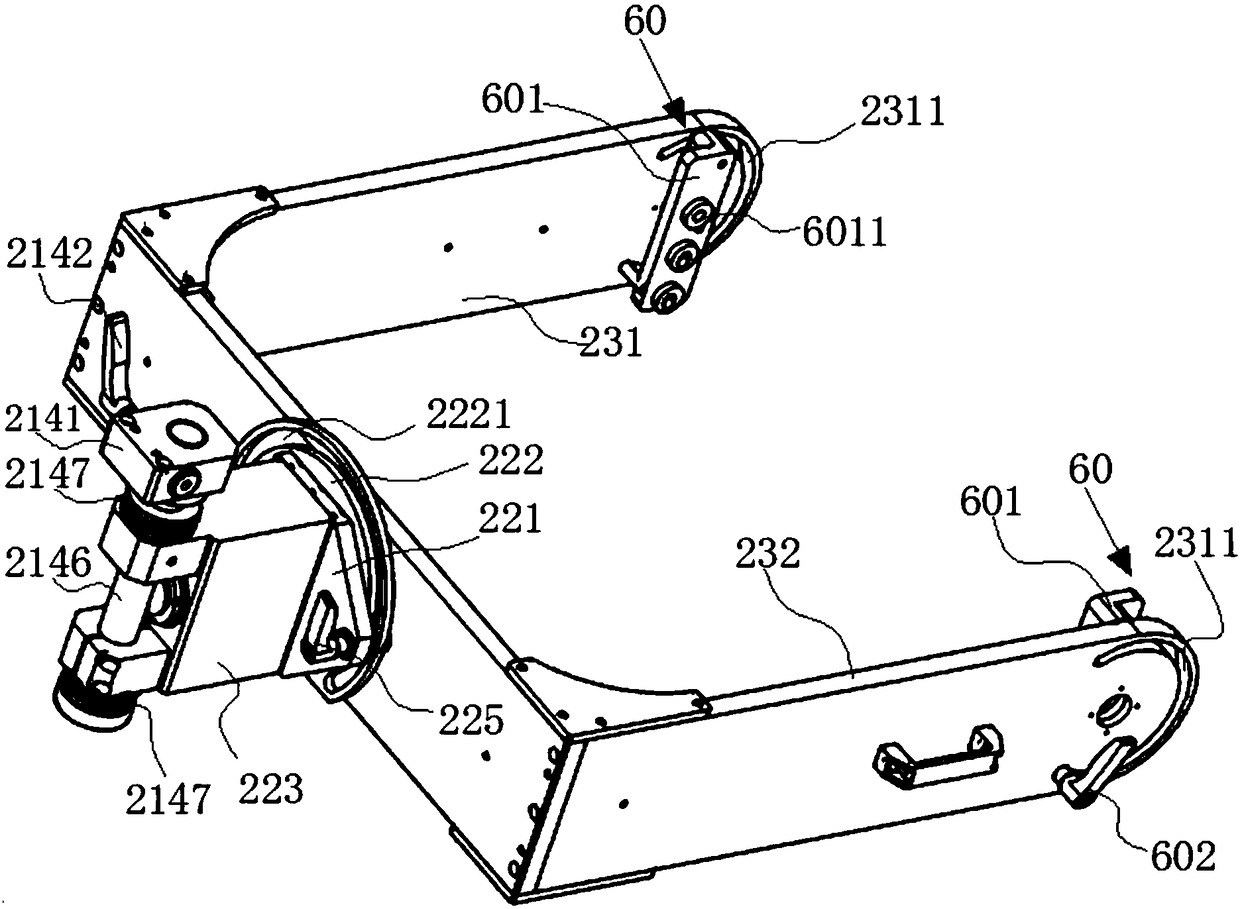

[0038] Such as figure 2 As shown, the manipulator 20 includes a reversing structure 21, an adjustable locking structure 22 and a clamping arm 23, one end of the locking structure is connected to the reversing structure, and the other end is connected to the clamping arm The arm of the clamping arm includes a left arm 231 and a right arm 232 capable of clamping the test equipment, the left arm and the right arm are parallel to each other, defining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com