Sensorless compound control method for permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and compound control, which is applied in motor control, motor generator control, electronic commutation motor control, etc., to achieve strong anti-interference and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

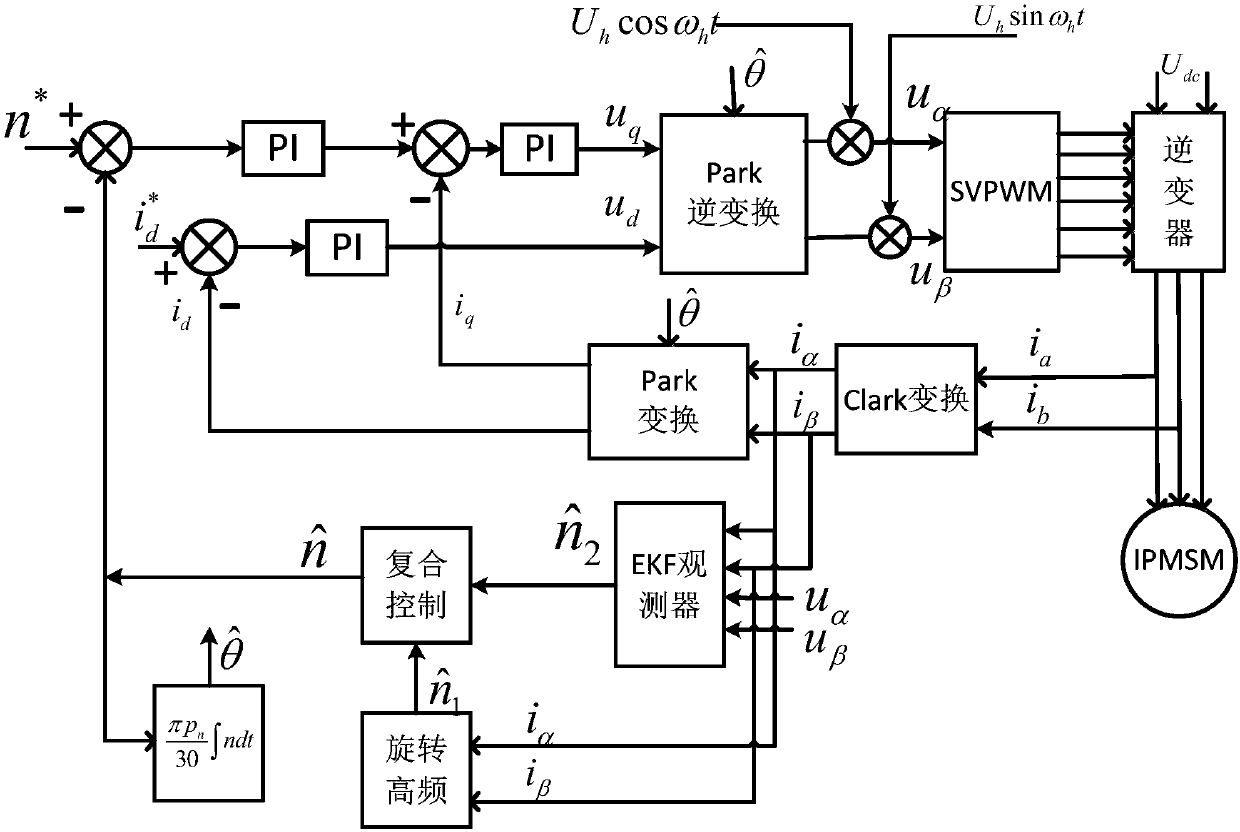

[0039] This embodiment is achieved through the following technical solutions. A sensorless composite control method for a permanent magnet synchronous motor is used to control a permanent magnet synchronous motor, comprising the following steps:

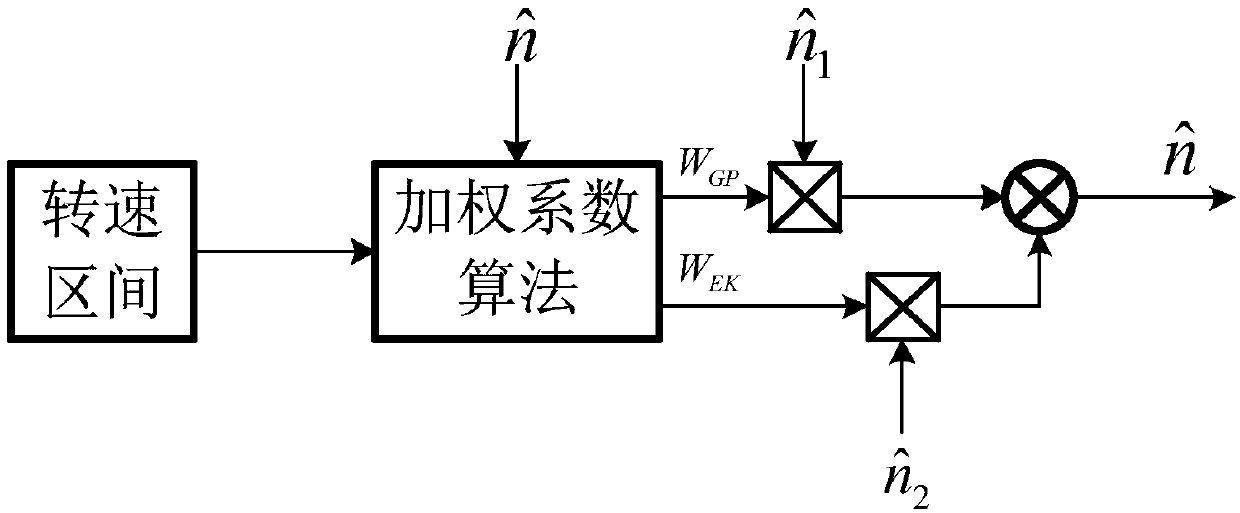

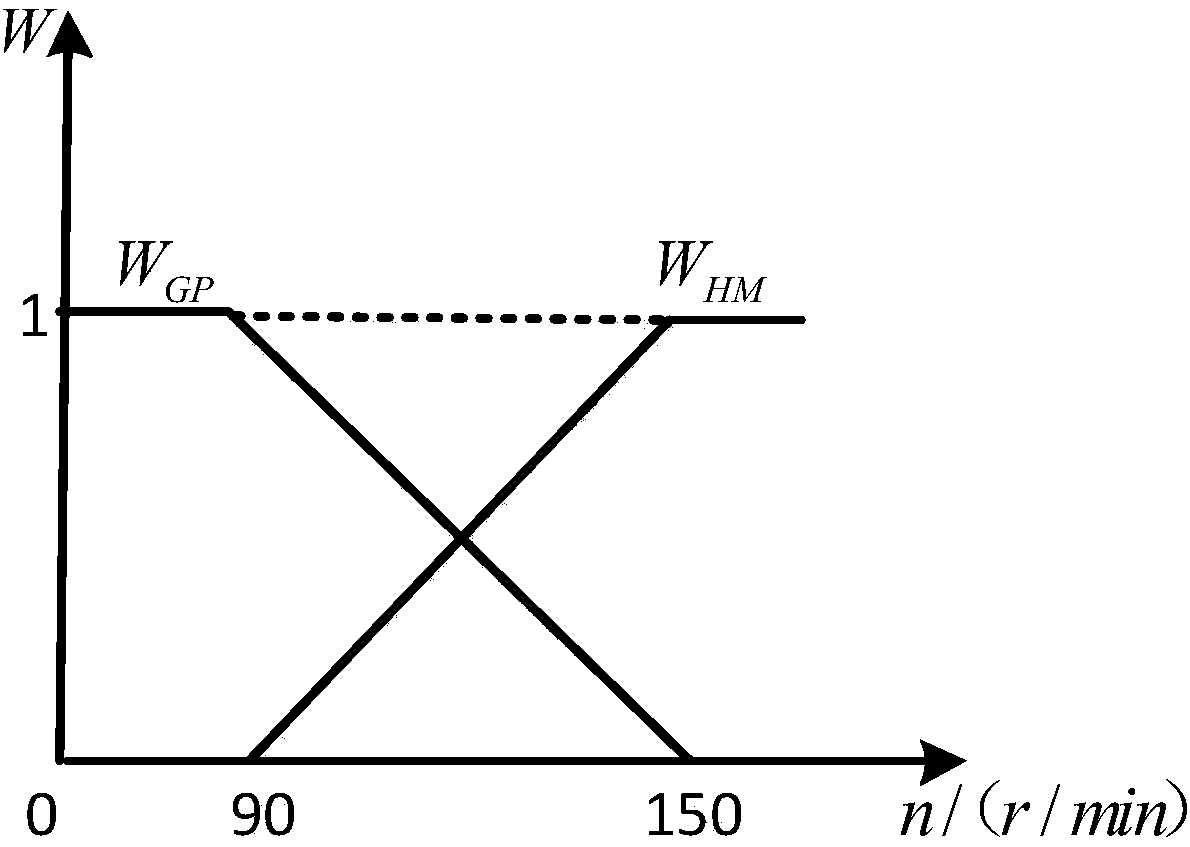

[0040] The sensorless control of the permanent magnet synchronous motor adopts the compound control method, and the control process is divided into three stages according to the output speed value calculated by the compound control: the first stage is zero, the low speed stage, and the upper limit of the speed is n min , this stage adopts the rotating high-frequency voltage injection method to detect the speed and rotor position; the second stage is the transition stage, and the upper and lower limits of the speed are respectively n max , n min , this stage adopts the composite control method to detect the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com