Novel high-precision shape-controlled plane grinding drive device

A technology of plane grinding and driving device, which is applied in the direction of grinding driving device, grinding device, grinding machine tool, etc., to achieve the effect of simple and compact structure, accurate and stable transmission, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

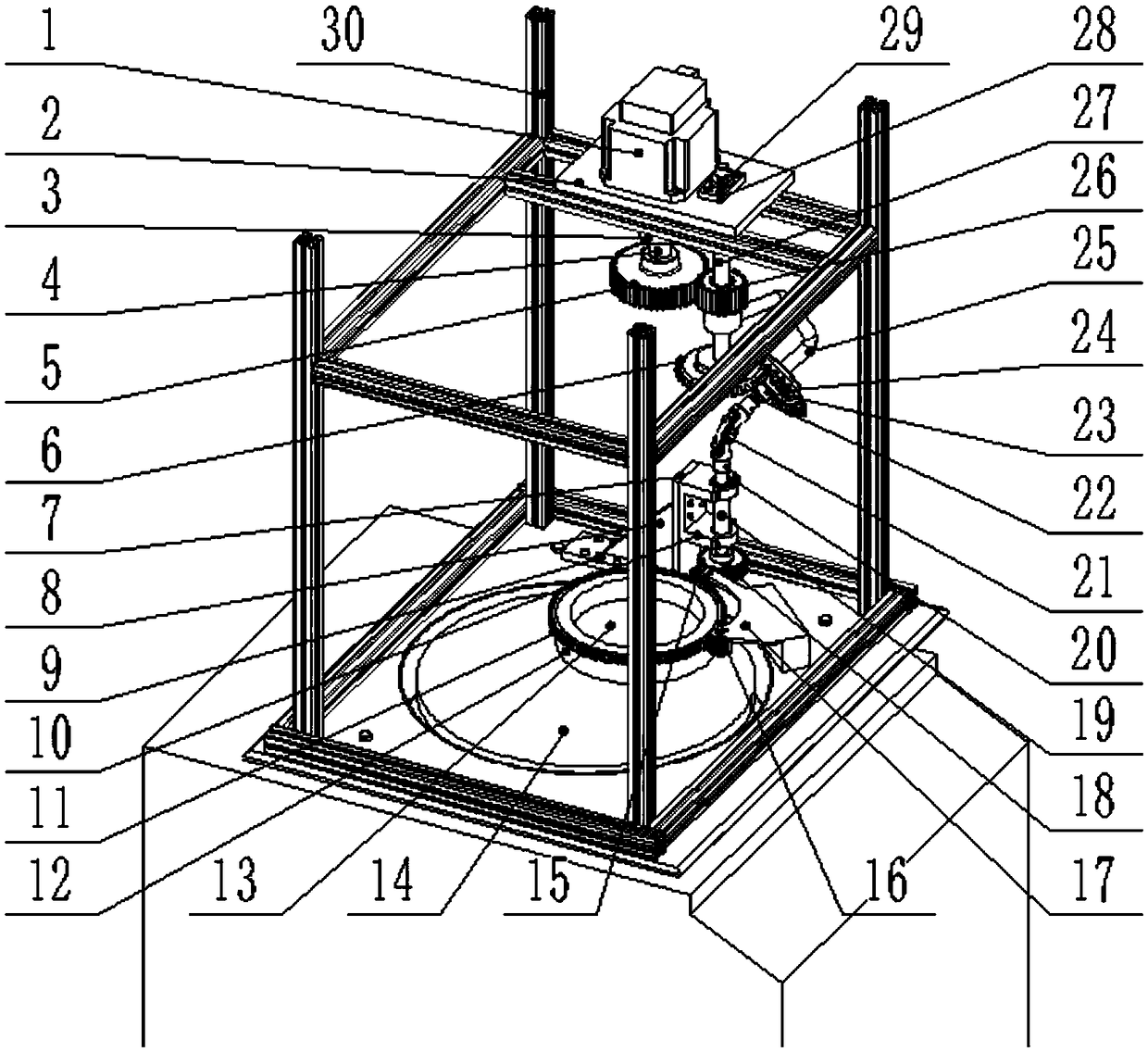

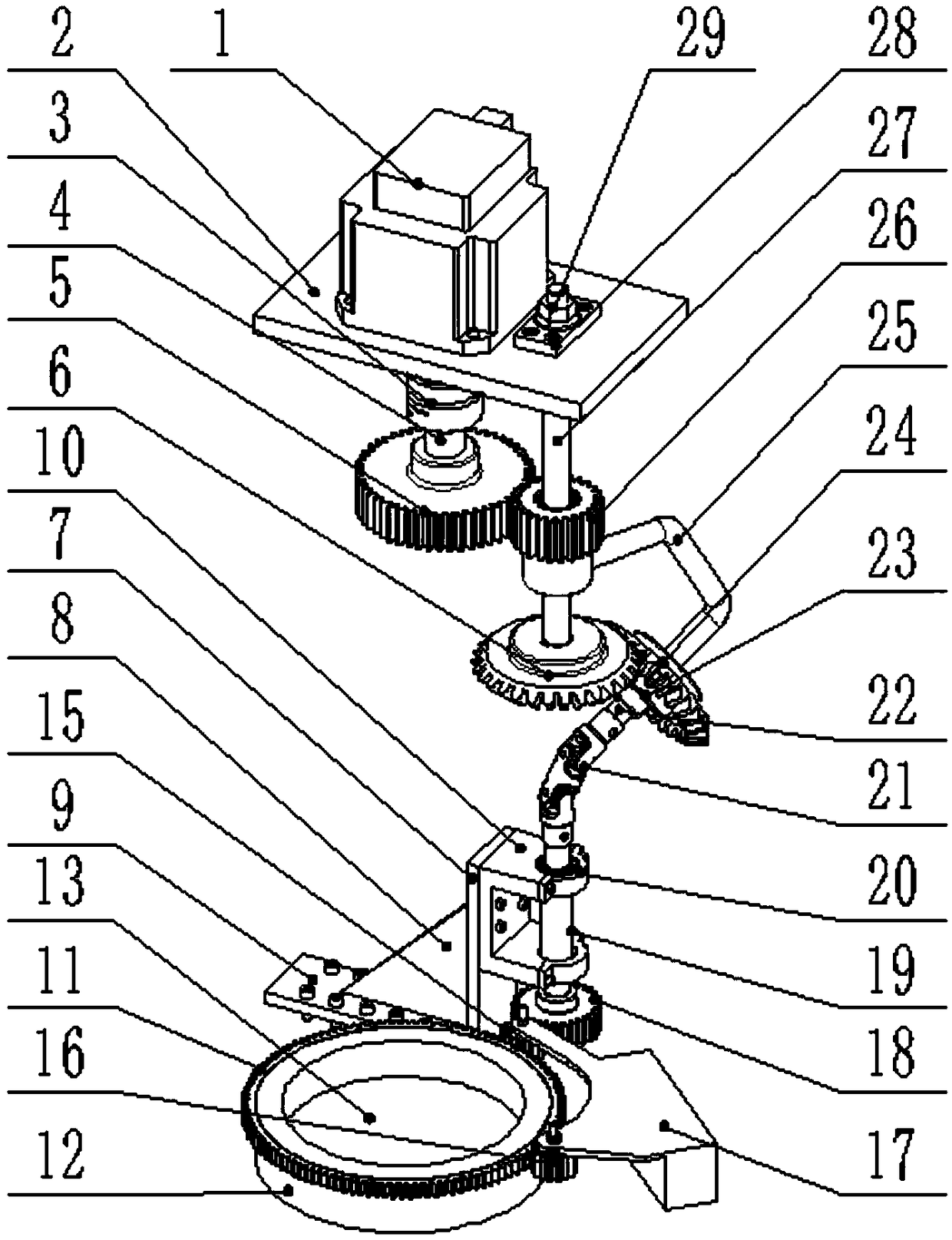

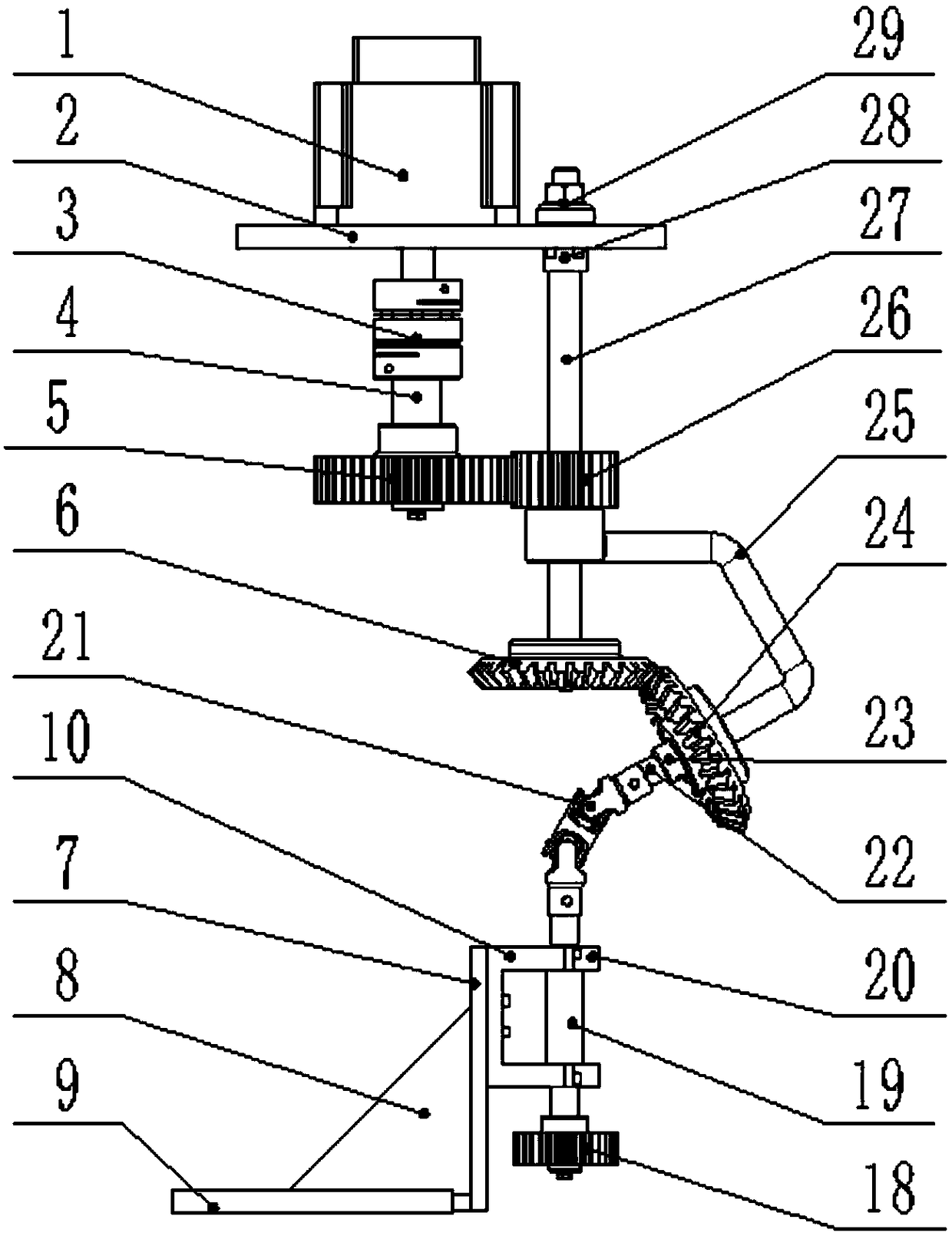

[0026] The invention will be further described below in conjunction with the accompanying drawings.

[0027] refer to Figure 1~6 , a new type of high-precision shape-controlled plane grinding drive device, including servo motor 1, motor seat plate 2, double-diaphragm coupling 3, shaft I4, gear I5, bevel gear I6, vertical plate 7, and rib plate 8 , horizontal plate 9, bearing seat 10, gear ring 11, trimming ring 12, workpiece disc 13, grinding disc 14, guide gear Ⅰ15, guide gear Ⅱ 16, cage 17, gear Ⅲ 18, shaft Ⅳ 19, bearing cover 20, double cross Shaft type universal coupling 21, shaft III 22, flange cover 23, bevel gear II 24, planet carrier 25, gear II 26, shaft II 27, fixed block 28, flange nut 29 and frame 30, the servo motor 1 is fixed Installed on the motor base plate 2, the motor base plate 2 is fixed on the frame 30 built with aluminum profiles, the upper end of the shaft I4 is connected with the servo motor 1 through the double-diaphragm coupling 3, and the gear I5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com