Impact-resistant water tank template

A technology of impact resistance and water tank, which is applied to the configuration of water supply devices, water supply pools, buildings, etc., can solve problems such as hidden dangers, small spacing between tension bars, and safety issues, and achieve enhanced impact resistance to external forces, strong impact resistance, The effect of increasing the ability to resist load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

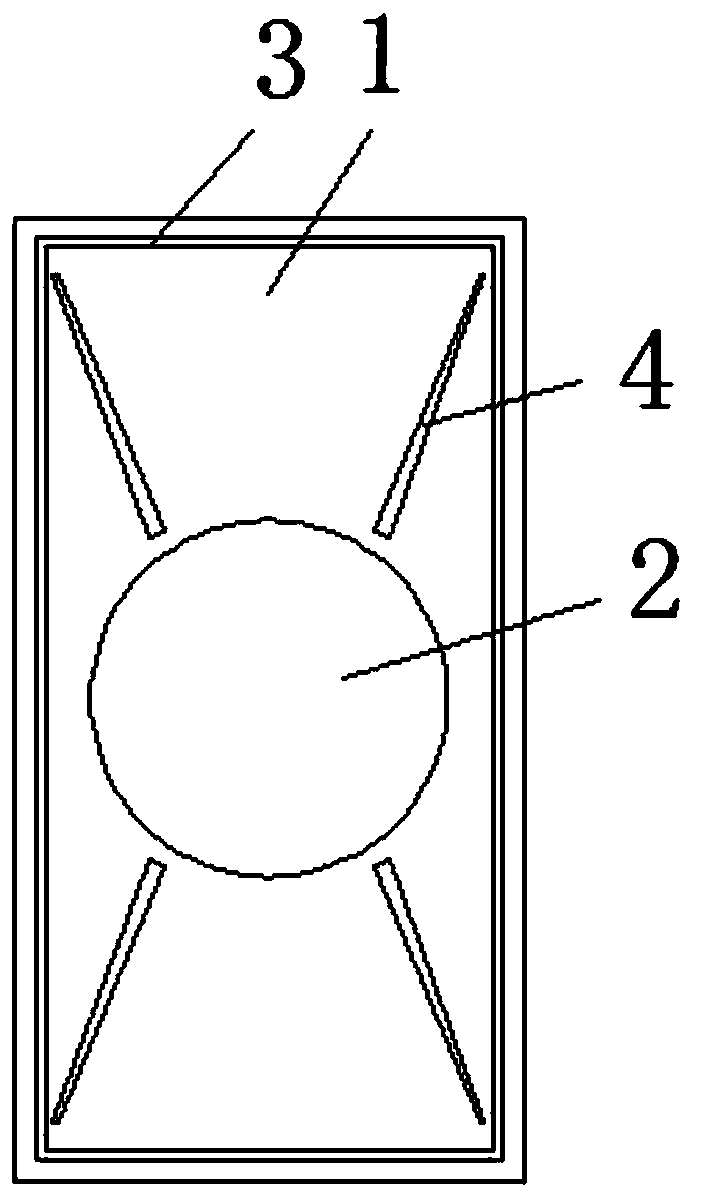

[0011] like figure 1 As shown, an impact-resistant water tank formwork includes a water tank formwork body 1, the water tank formwork body 1 is a rectangular structure, and an arc arch 2 is provided at the center of the pressure-bearing surface of the water tank formwork body 1. A mouth-shaped reinforcing groove 3 is arranged on the periphery of the arch surface 2, and a strip-shaped reinforcing groove 4 is provided at each four corners of the circular arc arch surface 2 near the mouth-shaped reinforcing groove 3, and the strip-shaped reinforcing groove 4 is formed by the circular arc arch surface 2 The opening of the mouth-shaped reinforcing groove 3 gradually becomes smaller.

[0012] In this embodiment, the mouth-shaped reinforci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com