Reinforcing device for angle steel power transmission tower main material

A reinforcement device and a technology for transmission towers, applied in towers, building maintenance, building types, etc., can solve problems such as inability to guarantee the safety of transmission towers, lack of mature and generally recognized technical measures, etc., and reduce the occurrence of tower collapse accidents , low cost, and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

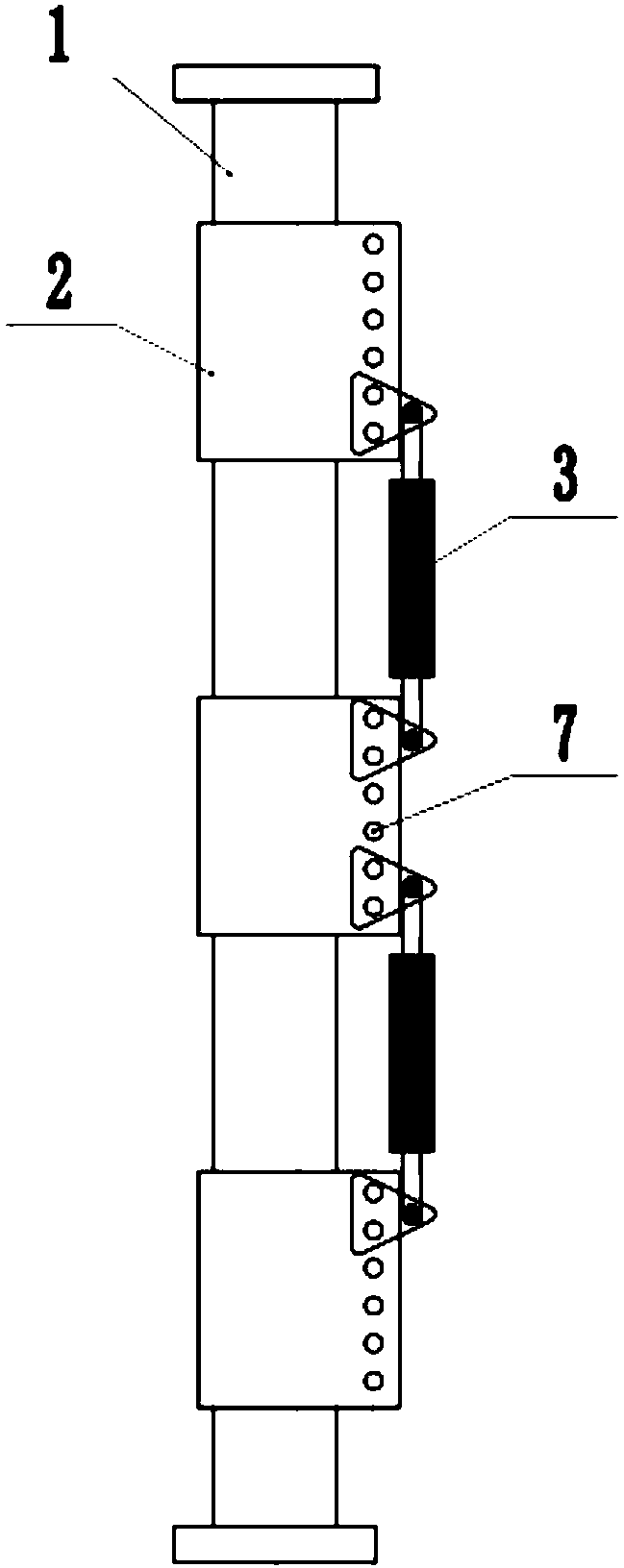

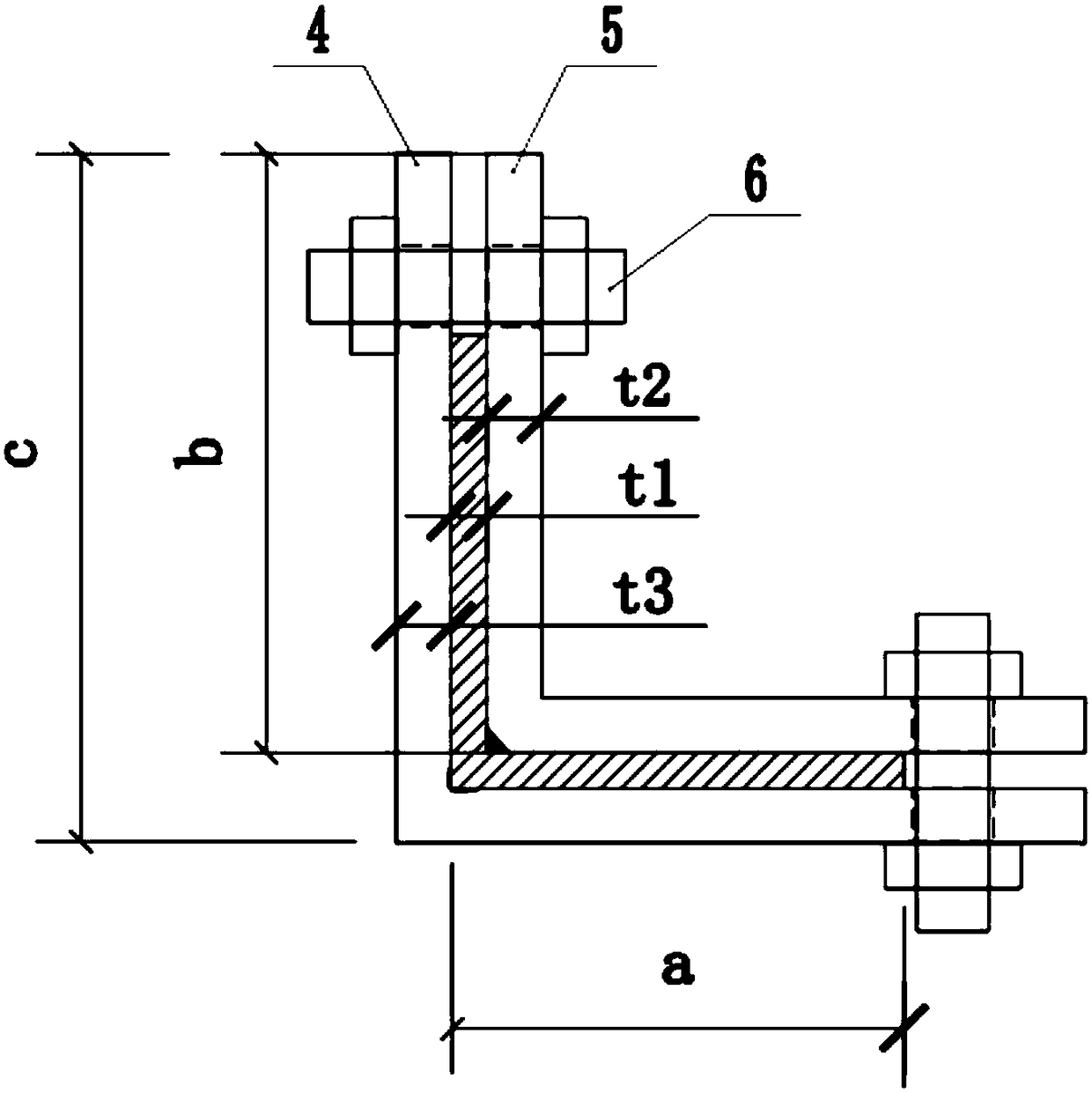

[0030] Such as Figure 1-3 As shown, a reinforcement device for the main material of an angle steel transmission tower includes a fixed auxiliary material 2, and the fixed auxiliary material 2 includes an outer auxiliary material 4 and an inner auxiliary material 5, and the outer auxiliary material 4 and the inner auxiliary material 5 are both Angle steel structure, the thickness of a single limb of the same angle steel is the same, the inner auxiliary material 5 is shoveled back, and the outer auxiliary material 4 is root-cleaned. Material 5 and outer auxiliary material 4 are arranged in the same direction as the main material of the transmission tower, the inner auxiliary material 5 is connected to the inner side of the main material of the transmission tower, and the outer auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com