Hydraulic load test system for crawler type walking device

A walking device and hydraulic loading technology, which is applied in vehicle trackless testing, fluid pressure actuating devices, machine gear/transmission mechanism testing, etc., can solve the problems of high energy consumption, large space occupation, and long test period, and achieve control accuracy The effect of high height, small footprint and short test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

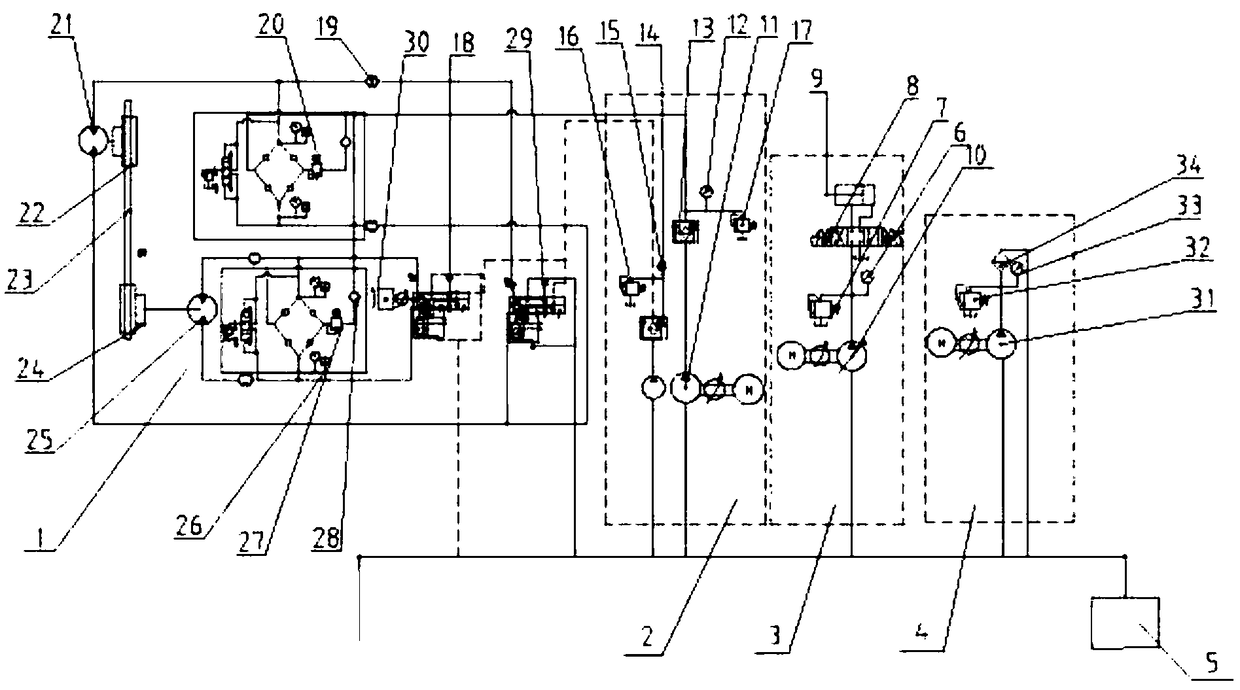

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0025] The invention provides a hydraulic loading test system for a crawler-type walking device. Its working principle is to control the pressure difference of the driving loading motor through the proportional overflow valve in the two selection circuits, and adjust the tension of the crawler belt through the tensioning unit. Displacement and pressure, in order to achieve the purpose of reducing equipment installation period, reducing manufacturing costs, improving experimental control accuracy and system versatility.

[0026] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

[0027] Such as figure 1 As shown, a hydraulic loading test system for a crawler-type traveling device, the system inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com