Decomposition method of gold ore sample

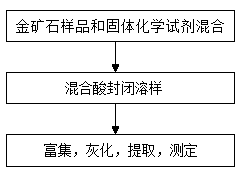

A gold ore and sample technology, applied in the field of precious metal analysis, can solve the problems of incomplete decomposition of samples with aqua regia and low results, and achieve the effects of simplified procedures, less volatilization of acid vapor, and avoiding the process of silicon removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

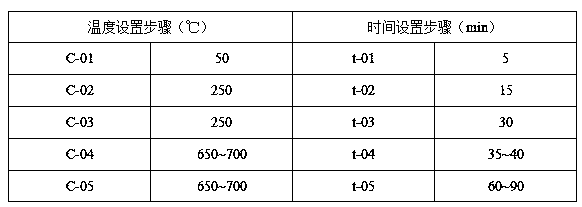

[0035] 1. Weigh 10g of quartz vein gold ore sample (GA1-Au-02) and 30g of ammonium bifluoride in a 50mL nickel crucible, mix well and place in a muffle furnace (furnace door slightly open), and heat up according to the set temperature program To 650 ℃, keep warm for 1h, take out and cool.

[0036] 2. Crush the agglomerated sample in the nickel crucible carefully with a glass rod, transfer it to a 250mL sample dissolving bottle, add a little water to moisten it; add 40mL 50% aqua regia (V / V), 4mL phosphoric acid (15mol / L) , Tighten the lid of the dissolving bottle and shake well. Put it in a closed water bath, dissolve for 1.5 hours, take it out and cool it, at this time the gold in the sample is completely decomposed.

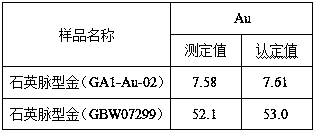

[0037] 3. Add water to 200mL, enrich the gold with activated carbon pulp, ash, extract with 5% aqua regia (V / V), set the volume to 25mL, and measure it with a flame atomic absorption spectrophotometer. The measurement results are shown in Table 2.

Embodiment 2

[0039] Example 2 is based on the basis of Example 1, in that the gold ore sample selected in this example is quartz vein gold ore (GBW07299). The measurement results are shown in Table 2.

Embodiment 3

[0041] 1. Weigh 10g of skarn sample (WB-1a#) and 30g of ammonium bifluoride in a 50mL nickel crucible, mix well and place in a muffle furnace (furnace door slightly open), and heat up to 700°C according to the set temperature program , keep warm for 1.5h, take out and cool.

[0042] 2. Crush the agglomerated sample in the nickel crucible carefully with a glass rod, transfer it to a 250mL sample dissolving bottle, add a little water to moisten it; add 50mL 50% aqua regia (V / V), 6mL phosphoric acid (15mol / L) , Tighten the lid of the dissolving bottle and shake well. Put it in a closed water bath, dissolve for 1.5 hours, take it out and cool it, at this time the gold in the sample is completely decomposed.

[0043] 3. Add water to 200mL, enrich the gold with activated carbon pulp, ash, extract with 5% aqua regia (V / V), set the volume to 25mL, and measure it with a flame atomic absorption spectrophotometer. The measurement results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com