Nitriding sintering method for silicon nitride and silicon carbide combined refractory product

A technology of nitriding firing and refractory products, which is applied in the field of nitriding firing of silicon nitride combined with silicon carbide refractory products, which can solve the problems of incomplete nitriding, low conversion rate, slow nitriding reaction speed, and inability of nitriding reaction Continue to wait for the problem to achieve the effect of solving the incomplete response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

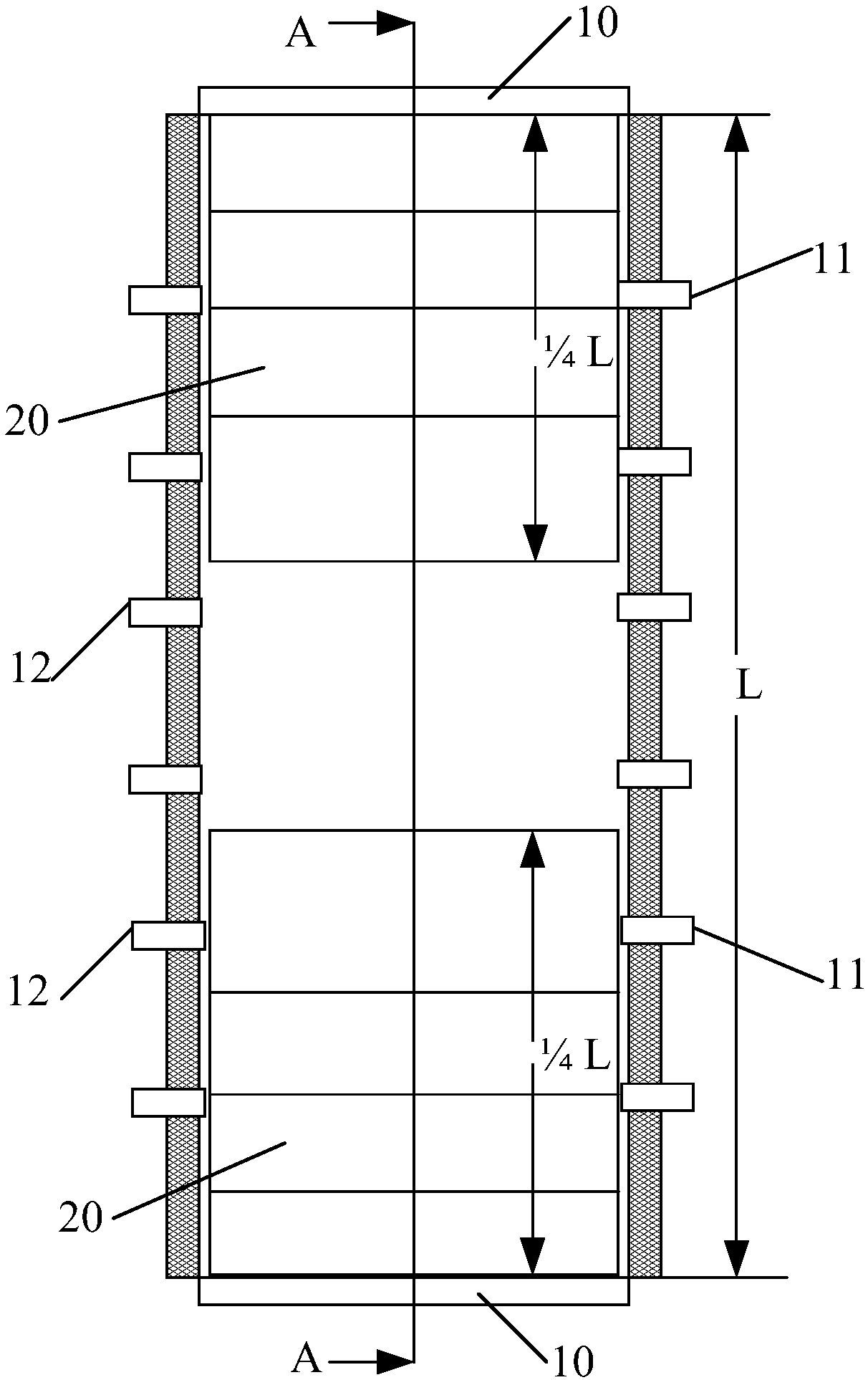

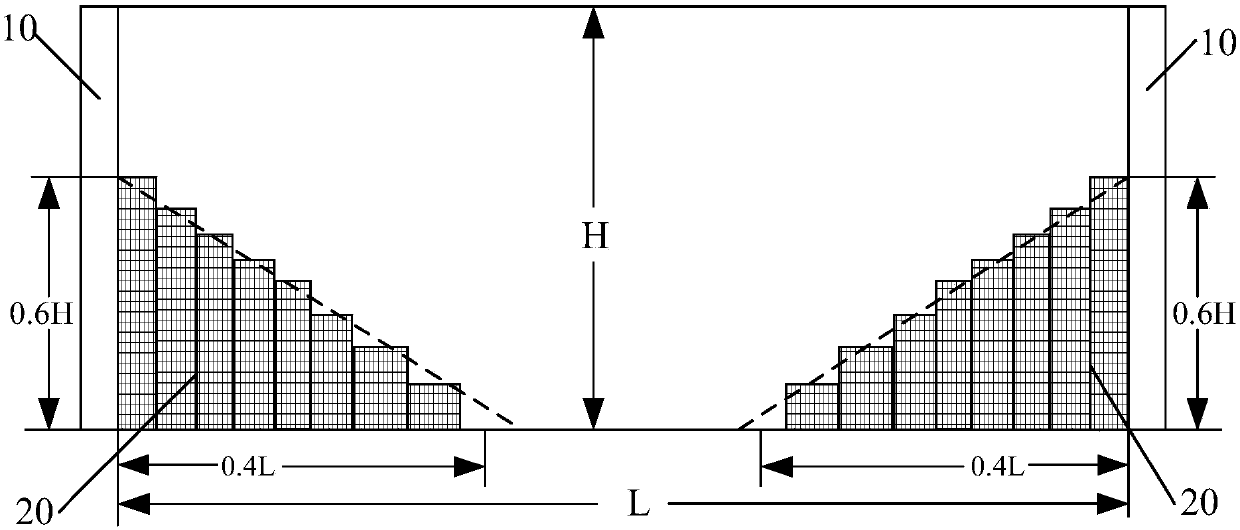

[0035] Industrial black silicon carbide, fine silicon powder and coarse silicon powder with a purity of more than 98% are selected as raw materials, and the particle size of fine silicon powder is D 50 15-20μm, fine silicon powder and industrial black silicon carbide are mixed, formed, and dried to obtain a 70mm thick low-temperature zone brick, and the particle size of coarse silicon powder is D 50 It is 65-76μm, and then coarse silicon powder and industrial black silicon carbide are mixed, formed, and dried to obtain 70mm thick bricks in the normal temperature zone to be fired with the bricks in the low temperature zone, and the bricks in the low temperature zone and normal temperature zone The volume ratio is 1:5, the highest nitriding firing temperature is monitored at 1400°C, the gas outlet is closed after the normal program keeps warm for 4 hours, and the N 2 Flow rate, until the nitriding furnace is at normal pressure, continue to keep warm for 6h, and then stop passing...

Embodiment 2

[0037] Industrial black silicon carbide, fine silicon powder and coarse silicon powder with a purity of more than 98% are selected as raw materials, and the particle size of fine silicon powder is D 50 10-15μm, fine silicon powder and industrial black silicon carbide are mixed, formed, and dried to obtain a 50mm thick low-temperature zone brick, and the particle size of coarse silicon powder is D 50 It is 48-65μm, and then coarse silicon powder and industrial black silicon carbide are mixed, formed, and dried to obtain 50mm thick bricks in the normal temperature zone to be fired with the bricks in the low temperature zone, and the bricks in the low temperature zone and normal temperature zone The volume ratio is 1:7, the maximum nitriding firing temperature is monitored at 1380°C, the gas outlet is closed after the normal program keeps warm for 6 hours, and the N 2 Flow rate, until the nitriding furnace is at normal pressure, continue to keep warm for 5h, and then stop passing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com