A device for improving the conversion rate of biodiesel

A technology of biodiesel and conversion rate, applied in chemical/physical/physicochemical nozzle reactors, fatty acid esterification, etc., can solve the problems of multiple processing procedures, serious pollution, low efficiency, etc., and achieve good social benefits and responsive The effect of long time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

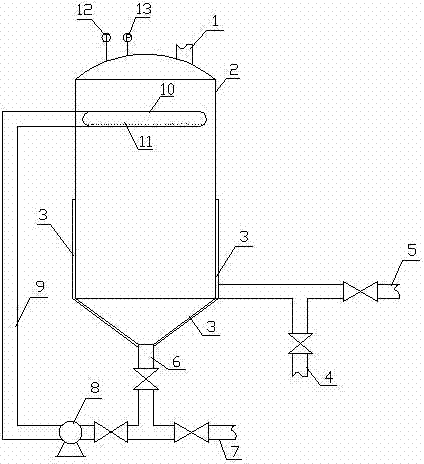

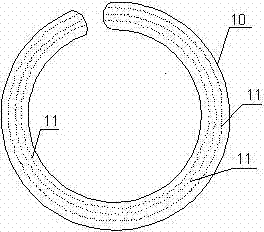

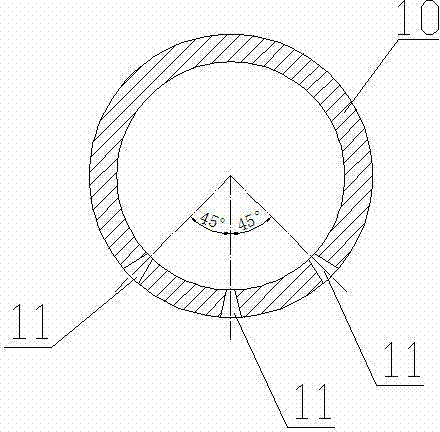

[0022] like figure 1 As shown, a device for improving the conversion rate of biodiesel, which includes a mixed liquid inlet pipe 1, a reaction kettle 2, a heating device 3, a product sampling port 4, a product outlet pipe 5, a mixed liquid outlet pipe 6, a liquid catalyst and a reaction By-product outlet pipe 7, temperature instrument 12, pressure instrument 13. The reaction kettle 2 is divided into upper and lower parts, the top of the upper part has a mixed liquid inlet pipe 1 near the edge, and a temperature gauge 12 and a pressure gauge 13 are arranged on the other side of the top. There is a mixed liquid outlet pipe 6 at the lower end of the reaction kettle 2, and the lower end of the mixed liquid outlet pipe 6 is connected with a liquid catalyst and a reaction by-product outlet pipe 7 at the same time. There is a product outlet pipe 5 at the conical surface of the reaction kettle 2, and the upper product outlet pipe 5 Connected with the product sampling port pipe 4. Fr...

Embodiment 2

[0027] like Figure 4As shown, a device for improving the conversion rate of biodiesel, which includes a mixed liquid inlet pipe 1, a reaction kettle 2, a heating device 3, a product sampling port 4, a product outlet pipe 5, a mixed liquid outlet pipe 6, a liquid catalyst and a reaction The basic structure of the by-product outlet pipe 7, the temperature instrument 12, and the pressure instrument 13 is the same as that of Embodiment 1. It also includes a mixed liquid circulation device and a mixed liquid spraying device. The mixed liquid circulation device is composed of a peristaltic pump 8 and a mixed liquid circulation delivery pipe 9. The lower end of the mixed liquid circulation delivery pipe 9 is equipped with a peristaltic pump 8. The mixed liquid outlet pipe 6 at the lower end of the reaction kettle 2 is connected to each other, and the upper end of the mixed liquid circulation delivery pipe 9 is located at the middle and upper part of the reaction kettle 2 and communi...

Embodiment 3

[0030] like Image 6 As shown, a device for improving the conversion rate of biodiesel, which includes a mixed liquid inlet pipe 1, a reaction kettle 2, a heating device 3, a product sampling port 4, a product outlet pipe 5, a mixed liquid outlet pipe 6, a liquid catalyst and a reaction The basic structure of the by-product outlet pipe 7, the temperature instrument 12, and the pressure instrument 13 is the same as that of Embodiment 1. It also includes a mixed liquid circulation device and a mixed liquid spraying device. The mixed liquid circulation device is composed of a peristaltic pump 8 and a mixed liquid circulation delivery pipe 9. The lower end of the mixed liquid circulation delivery pipe 9 is equipped with a peristaltic pump 8. The mixed liquid outlet pipe 6 at the lower end of the reaction kettle 2 is connected to each other, and the upper end of the mixed liquid circulation delivery pipe 9 is located at the middle and upper part of the reaction kettle 2 and communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com