Black bean seasoning paste and technology for processing same

A processing technology and a technology for seasoning sauce, applied in the field of black bean seasoning sauce and its processing technology, can solve the problems of complex production, low toughness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

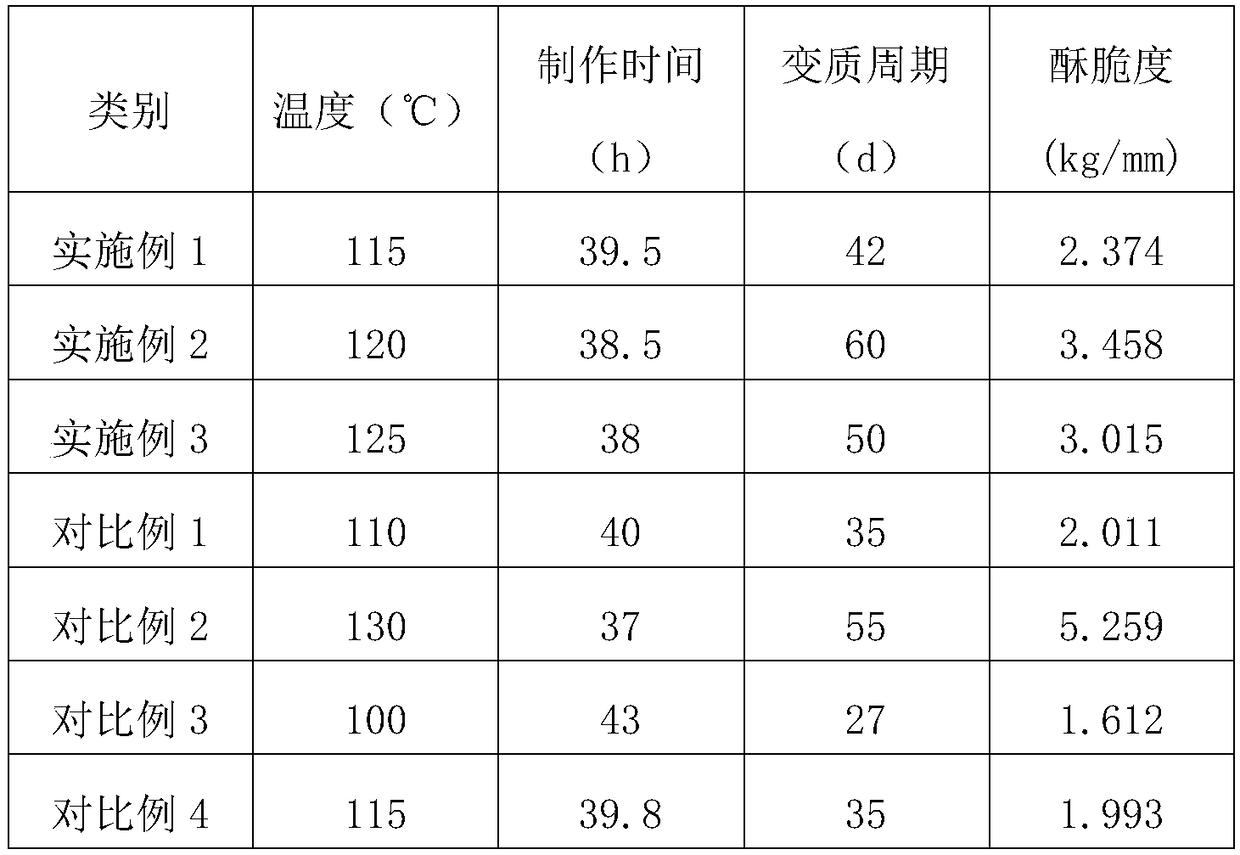

Examples

Embodiment 1

[0021] A processing technology of black bean sauce, comprising the following steps:

[0022] Step 1: Prepare raw materials, which include: black beans, peanut oil or palm oil, light soy sauce, and chili peppers. The parts by weight of each raw material are: 8 parts of black beans, 8 parts of vegetable oil, 8 parts of light soy sauce, and 1 part of pepper. Wash the black beans, and then Soak it in water at 12-15°C for 11-12 hours;

[0023] Step 2: Cook the soaked black beans at 0.169mpa and 115°C for 2 hours;

[0024] Step 3: Drain the steamed black beans and let them stand for 4 hours;

[0025] Step 4: Put peanut oil or palm oil into the pot and heat to 80°C, then add chili and stir-fry for 5 minutes to obtain chili oil;

[0026] Step 5: Put the standing black soybeans into the chili oil and stir-fry for 5 minutes, then add light soy sauce until the black soybeans are submerged, then heat it to 80°C and turn off the heat to prepare the black soybean sauce.

Embodiment 2

[0028] A processing technology of black bean sauce, comprising the following steps:

[0029] Step 1: Prepare raw materials, which include: black beans, peanut oil or palm oil, light soy sauce, and chili peppers. The parts by weight of each raw material are: 8 parts of black beans, 8 parts of vegetable oil, 8 parts of light soy sauce, and 1 part of pepper. Wash the black beans, and then Soak it in water at 12-15°C for 11-12 hours;

[0030] Step 2: Cook the soaked black beans for 1.75 hours at 0.2mpa and 120°C;

[0031] Step 3: drain the steamed black beans and let stand for 6 hours;

[0032] Step 4: Put peanut oil or palm oil into a pot and heat to 85°C, then add chili and stir-fry for 8 hours to obtain chili oil;

[0033] Step 5: Put the standing black beans into the oily chili and stir-fry for 8 minutes, then add light soy sauce until the black beans are submerged, then heat it to 90°C and turn off the heat to prepare the black bean sauce.

Embodiment 3

[0035] A processing technology of black bean sauce, comprising the following steps:

[0036] Step 1: Prepare raw materials, which include: black beans, peanut oil or palm oil, light soy sauce, and chili peppers. The parts by weight of each raw material are: 8 parts of black beans, 8 parts of vegetable oil, 8 parts of light soy sauce, and 1 part of pepper. Wash the black beans, and then Soak it in water at 12-15°C for 11-12 hours;

[0037] Step 2: steaming the soaked black beans for 2 hours at 0.232mpa and 125°C;

[0038] Step 3: Drain the steamed black beans and let stand for 8 hours;

[0039] Step 4: Put peanut oil or palm oil into a pot and heat to 90°C, then add chili and stir-fry for 10 hours to obtain chili oil;

[0040] Step 5: Put the standing black soybeans into the chili oil and stir-fry for 10 minutes, then add light soy sauce until the black soybeans are submerged, then heat it to 100°C and turn off the heat to prepare the black soybean sauce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com