Zero-pressure connector

A zero-pressure, zero-compression technology, applied to needles, devices introduced into the body, etc., can solve the problems of poor patient recovery and high infection risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

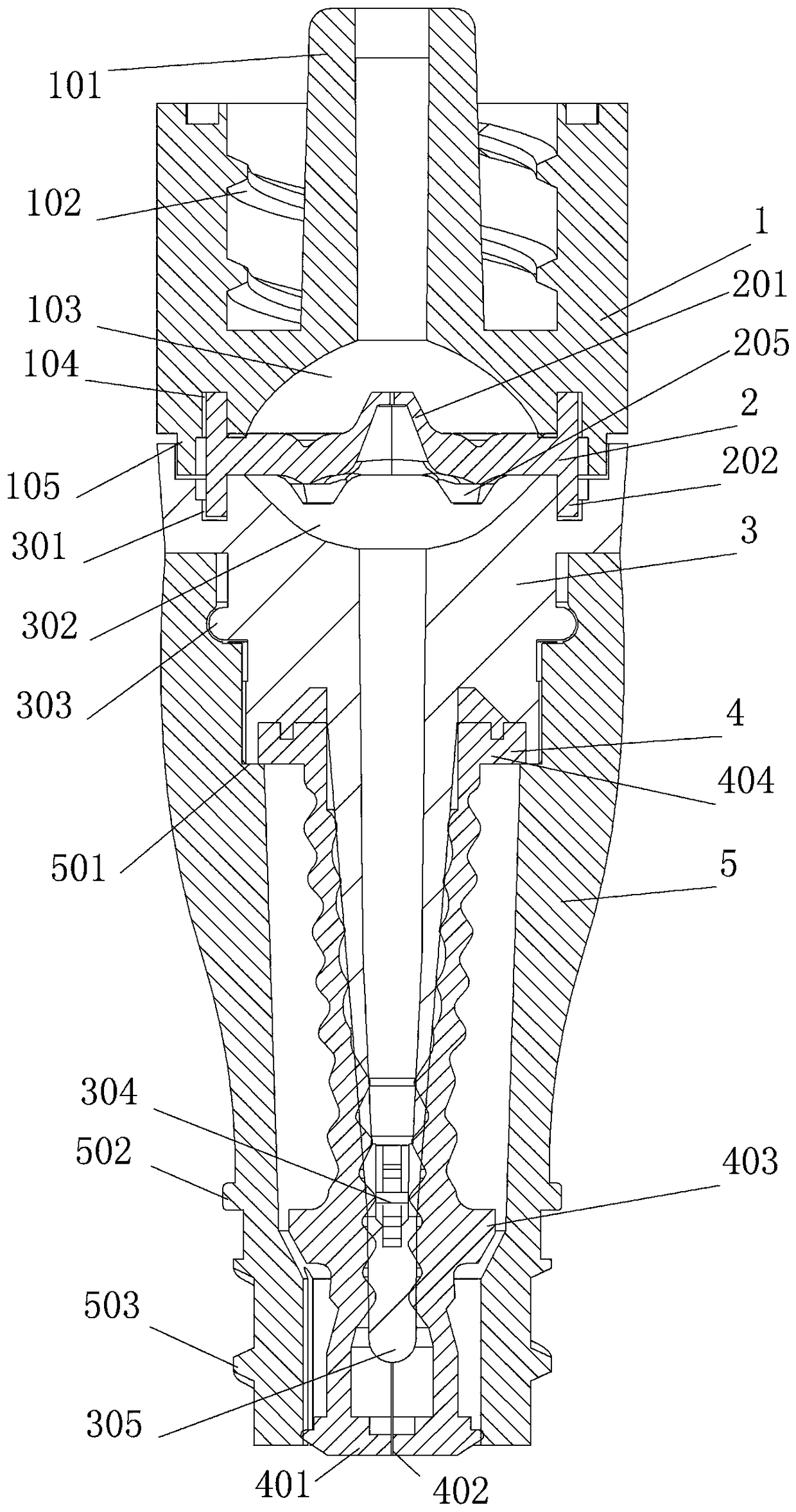

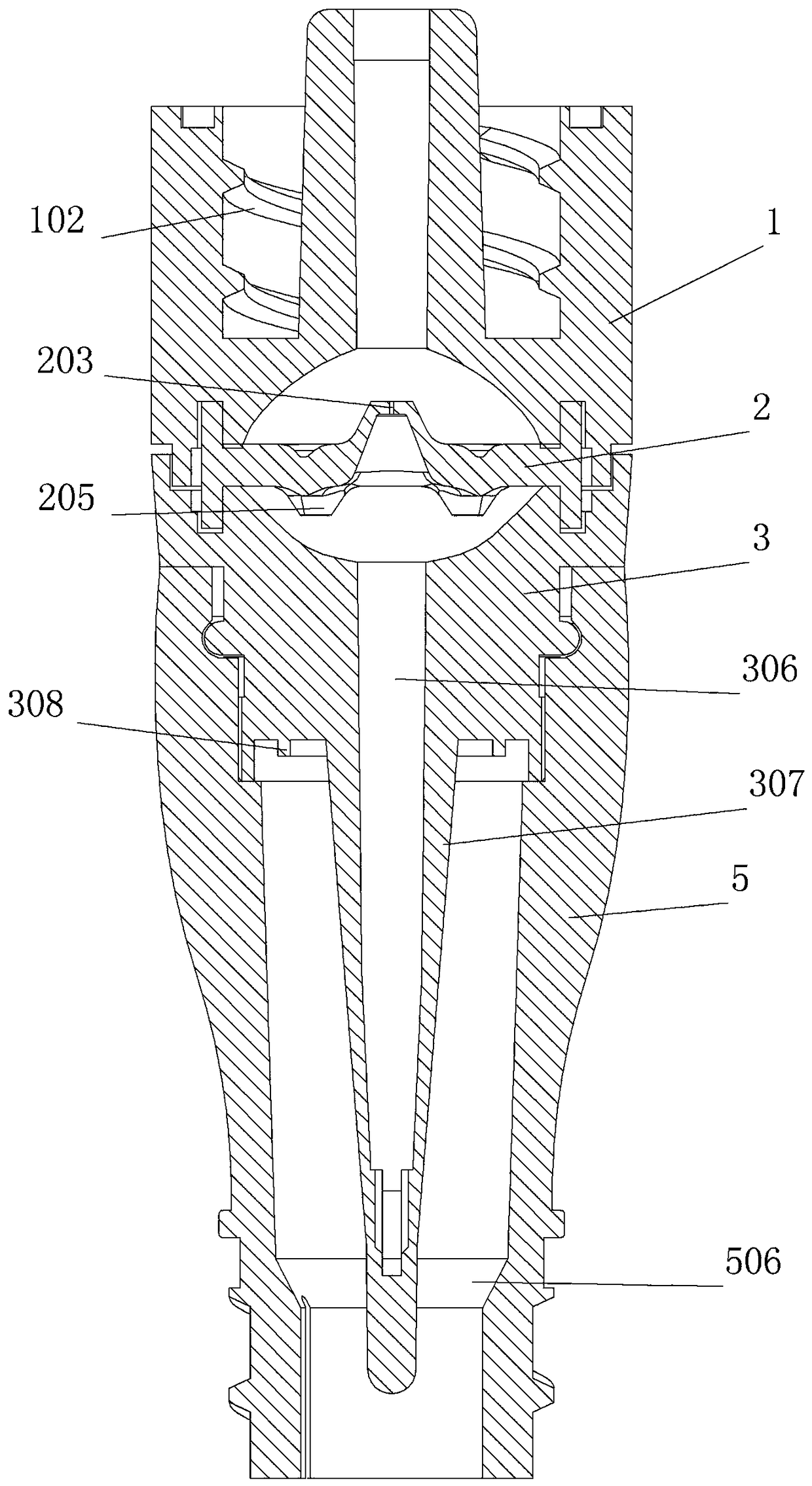

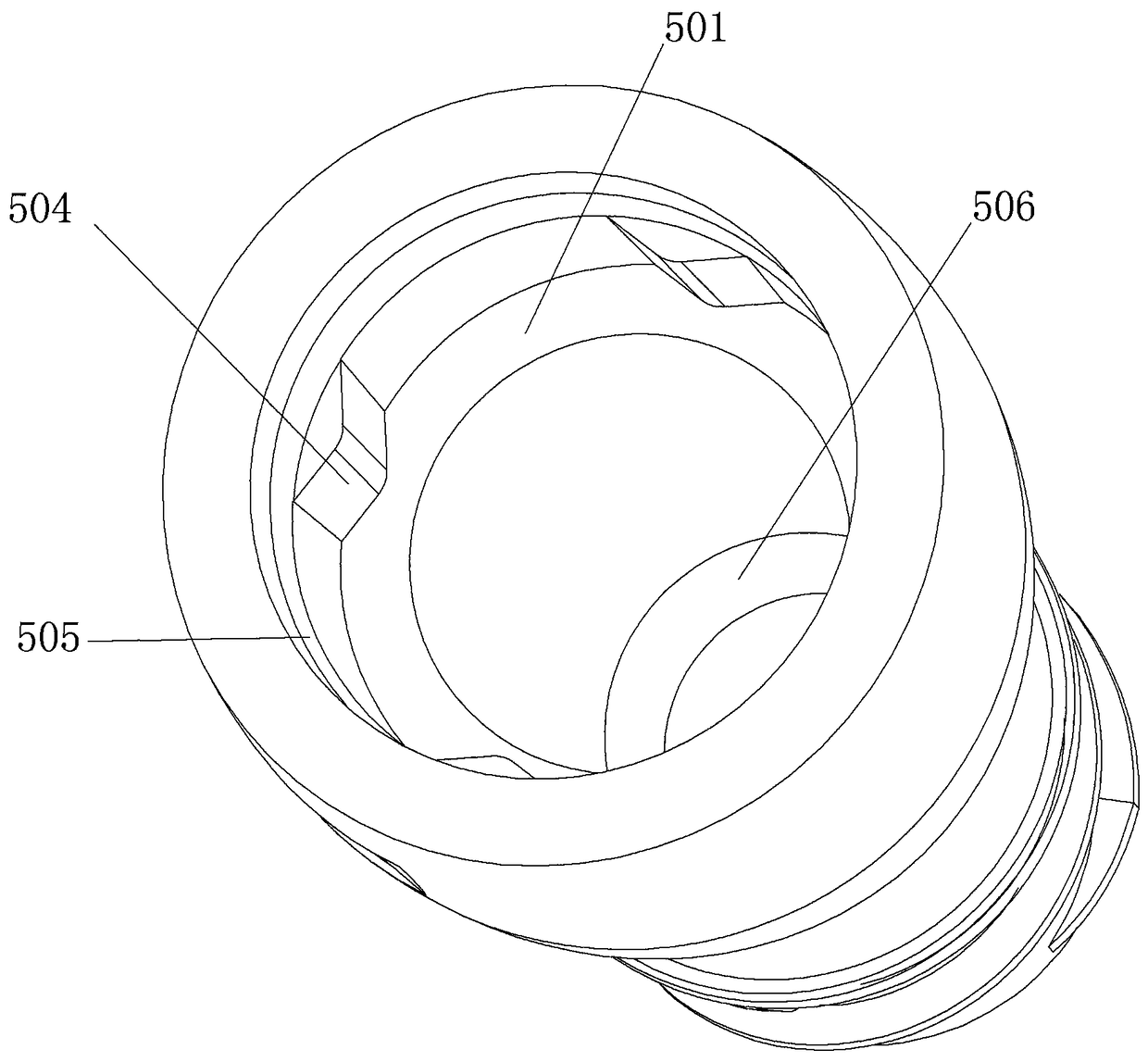

[0031] Embodiment one: see Figure 1-8 , a zero-pressure joint in the figure, which is mainly composed of an upper shell, a zero-pressure sheet, a drainage tube, a sealing sleeve, and an outer shell. Its characteristics are:

[0032] The upper shell is a cylinder, and the center has a joint protruding from the upper surface of the upper shell. The joint is a hollow cylinder, and its lower part is connected with the shell to divide the inner space of the upper shell into upper and lower parts. The upper part is surrounded by Internal thread, the middle part is the cylinder, this structure is convenient to connect with the upper joint which is a common joint; the lower part of the joint port has an upper hemispherical cavity, the outer side of the upper hemispherical cavity wall has an upper fixing groove, and the outer side of the upper fixing groove is the upper shell wall , There are protruding fixing ribs on the lower surface of the upper housing wall near the upper fixing g...

Embodiment 2

[0041] Embodiment two, according to the zero-pressure joint of embodiment one, its use method is:

[0042] ①. Connect the upper joint with the internal thread in the upper housing;

[0043] ②. Align the ribs in the middle of the lower joint with the sealing disc of the sealing sleeve, and forcefully push the sealing disc into the casing. At this time, the lower end of the drainage tube pushes the sealing disc through the gap in the middle, and the ribs continue to move up, so that The sealing plate is located above the drainage port, so that the interior of the drainage tube communicates with the interior of the lower joint; the lower joint is connected to the lower end of the shell through external threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com