Coralloidal Zn-ZnO composite material and preparation method thereof

A composite material and coral-like technology, which is applied in the field of coral-like Zn-ZnO composite materials and their preparation, can solve problems such as inaccessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Weigh 0.5-5g of CTAB and dissolve it in 250-2500ml of water, and keep stirring evenly at 80°C, then add 1.5-6.5ml of 2mol / L sodium hydroxide solution and continue stirring until uniform, then add 2.5-5g of Continue to stir zinc acetate dihydrate until uniform, then slowly add lithium hydroxide until the solution is slightly alkaline, stir the mixture at 80°C for 1-4h and filter the mixed solution obtained, and filter the filtered product in an electric heating blower Dry at 60°C for 24h, then put the dried powdery product into a crucible, and calcinate in a muffle furnace at 500°C for 2-8h to obtain the product ordered mesoporous zinc oxide matrix.

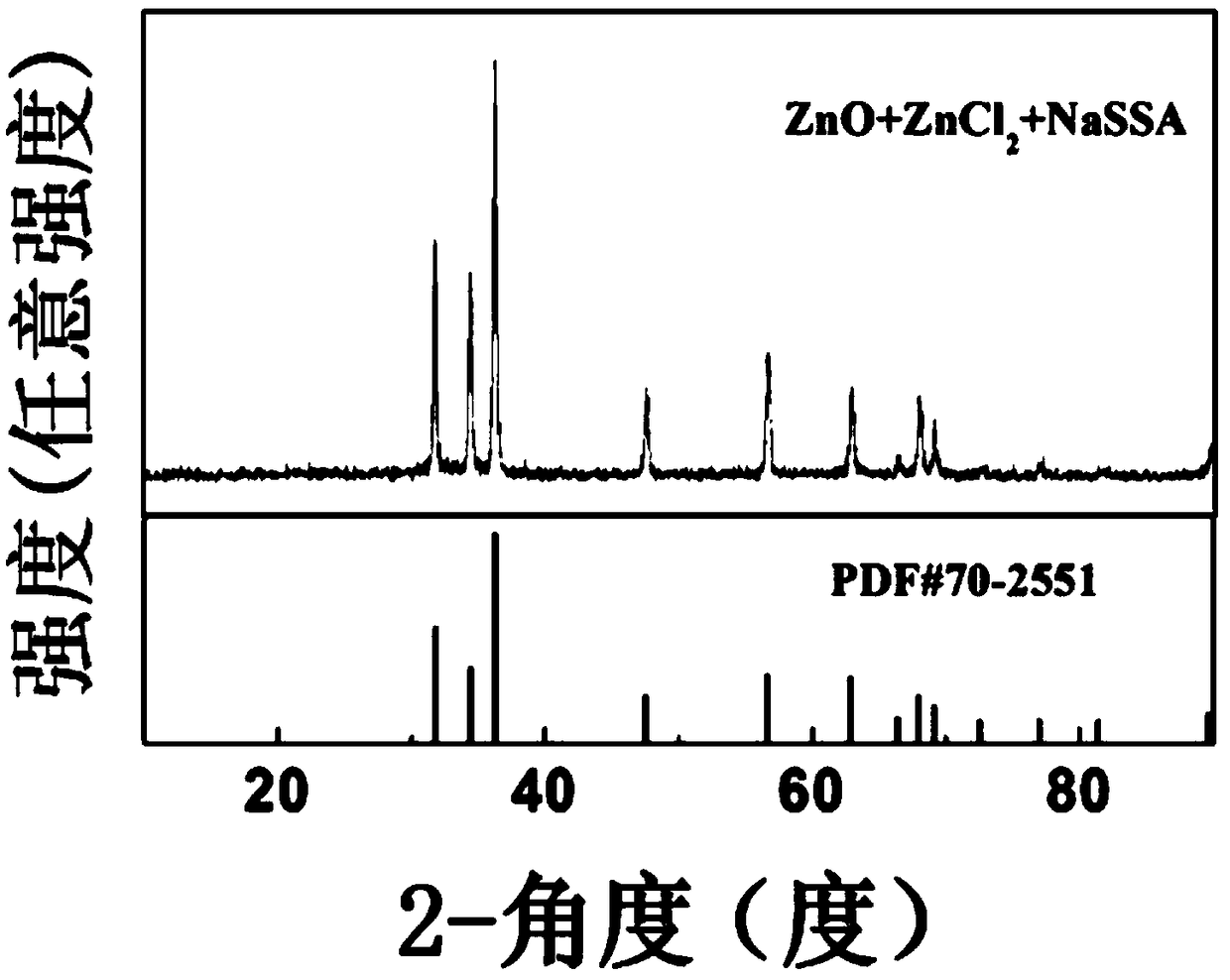

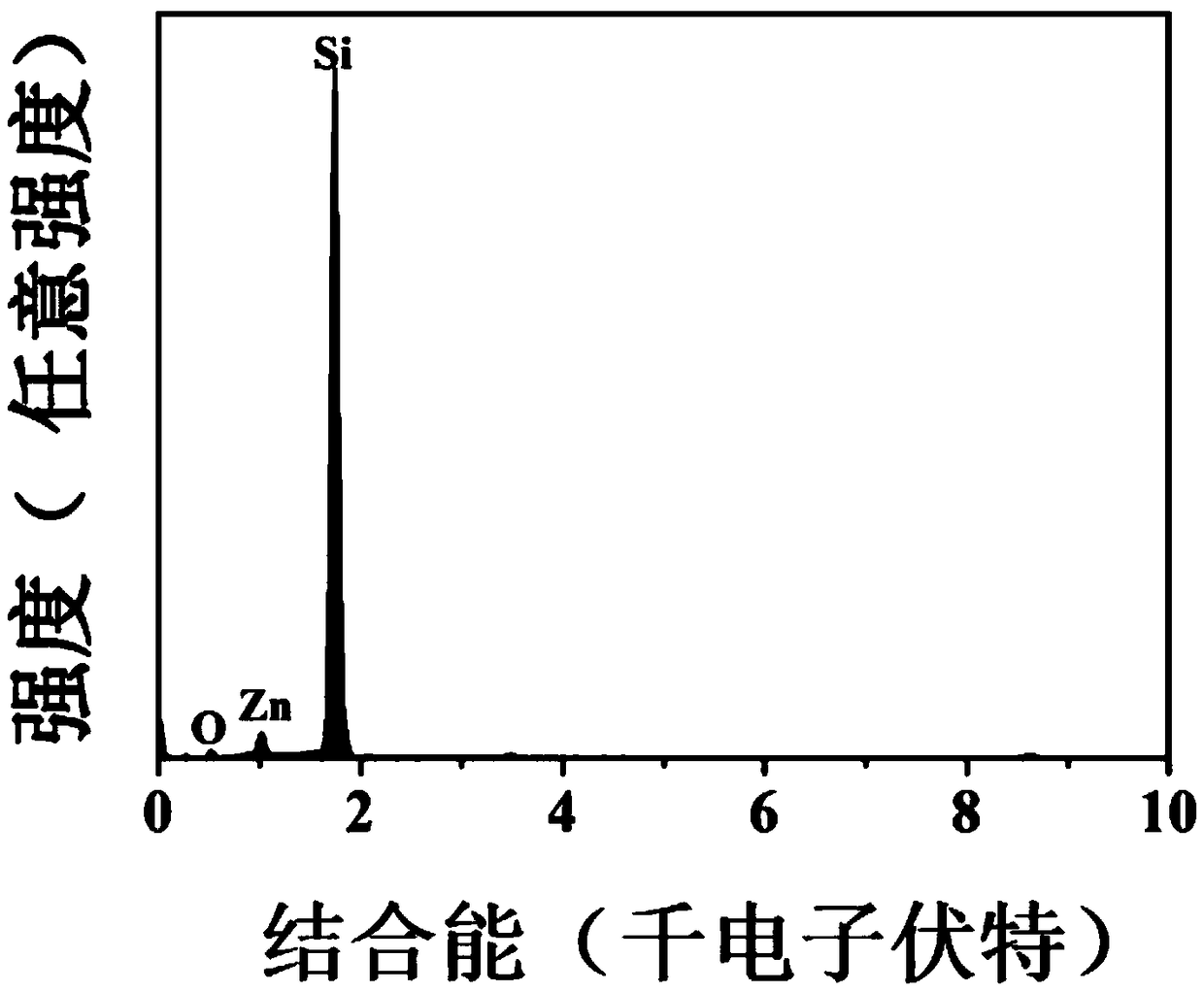

[0030] Weigh 0.1-1g zinc chloride, 0.5-3.5g sodium sulfosalicylate and 0.4-5g ordered mesoporous zinc oxide prepared above into a clean beaker, add appropriate amount of deionized water and keep stirring at room temperature 12-48h, then pour the obtained mixture into a polytetrafluoroethylene reactor, react in a dry box at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com