Pipeline drilling machine

A drilling machine and pipeline technology, which is applied in the directions of portable drilling rigs, drilling/drilling equipment, metal processing machinery parts, etc. and other problems, to achieve the effect of improving drilling efficiency, small volume, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

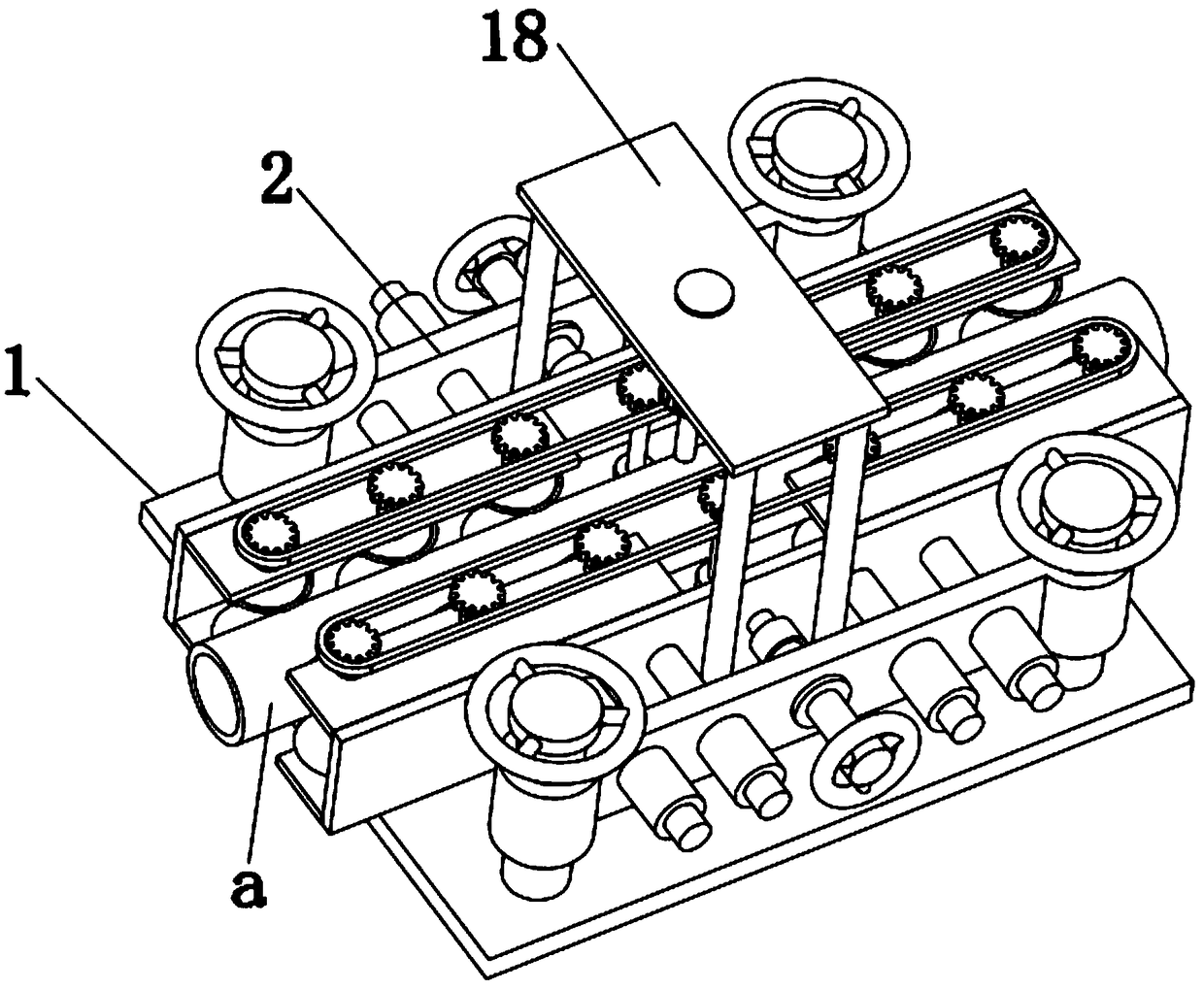

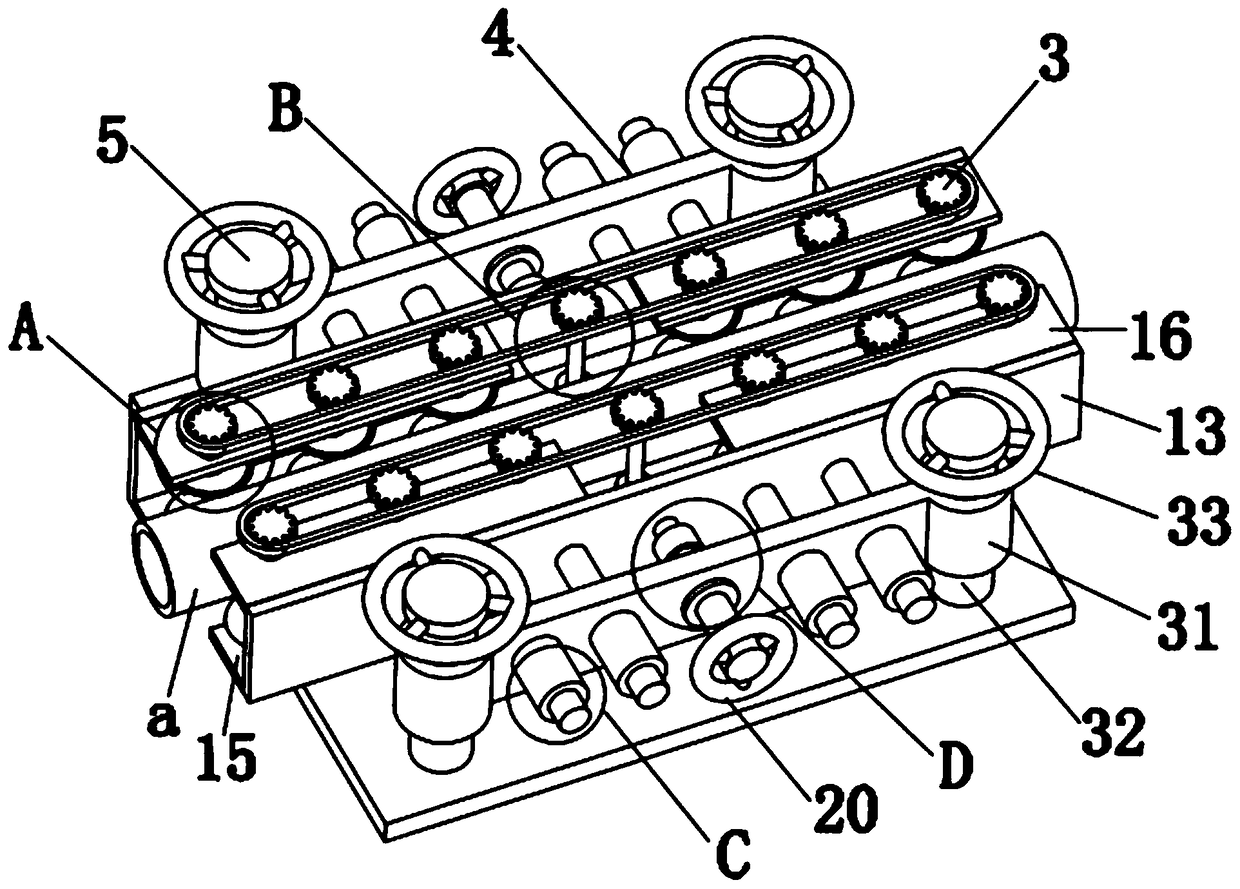

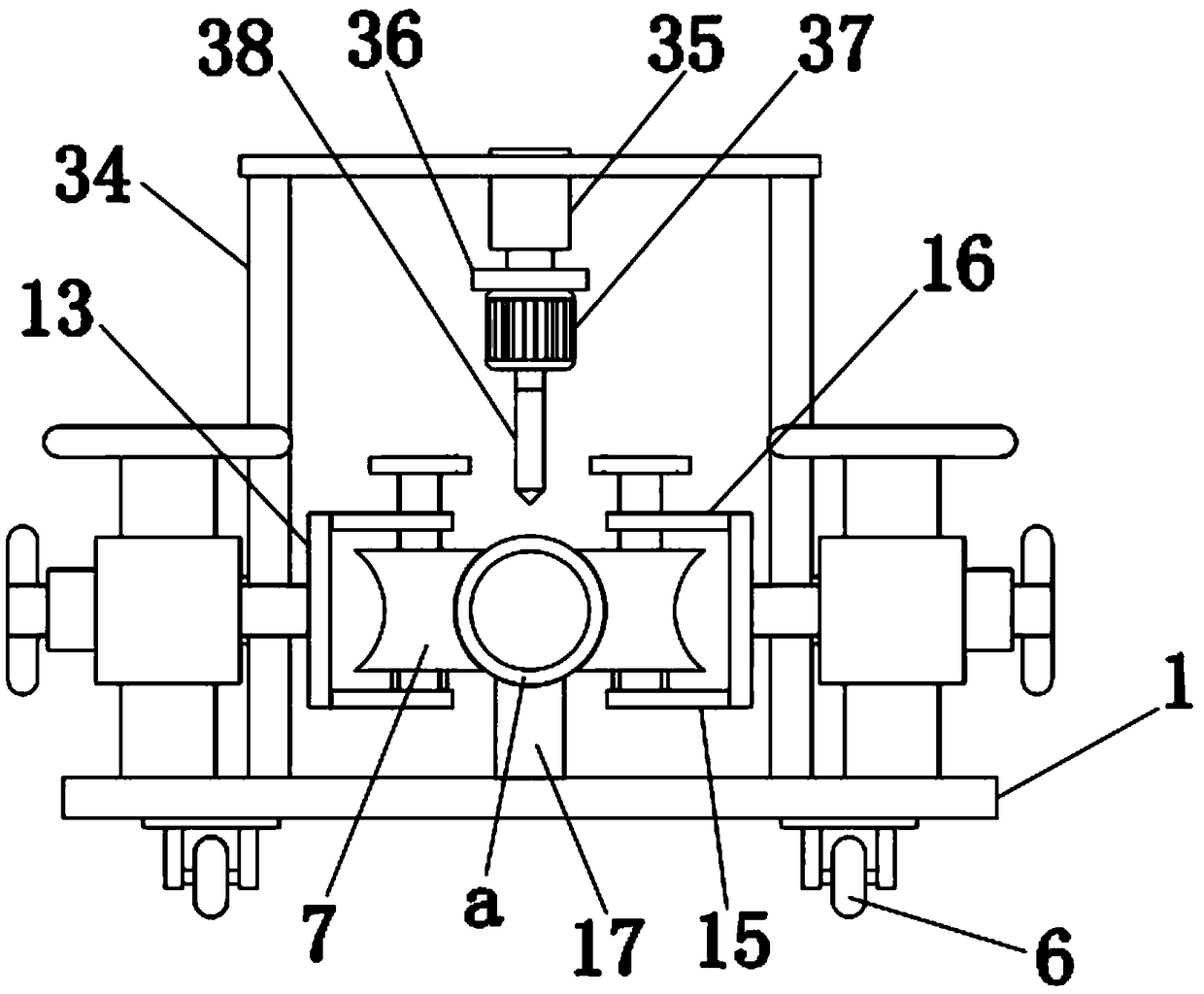

[0036] Embodiment one please refer to Figure 1-8, a pipeline drilling machine, including a support plate 1 and a fixing device 2, the top of the support plate 1 is fixed with a fixing device 2, and the fixing device 2 includes a progressive device 3, a horizontal adjustment device 4 and a longitudinal adjustment device 5 , the advancing device 3 is provided with two, the two advancing devices 3 are symmetrically distributed above the support plate 1, and the two advancing devices 3 are located on both sides of the pipeline a, and the advancing device 3 includes a driving roller 7, Gear chain 8, driven gear 9, driving gear 10, rotating shaft 11, progressive motor 12, fixed plate 13, connecting shaft 14, first connecting plate 15 and second connecting plate 16, the bottom of described fixing plate 13 one side and the top are respectively fixed with a first connecting plate 15 and a second connecting plate 16, the progressive motor 12 is fixed on the top of the first connecting ...

Embodiment 2

[0037] Embodiment 2 Please refer to Figure 1-8 , the outer side of the driving roller 7 is an arc-shaped structure, and the outer side of the driving roller 7 is fixed with an anti-skid pad 19 . Such setting increases the contact area between the driving roller 7 and the pipeline, preventing slippage between the driving roller 7 and the pipeline.

Embodiment 3

[0038] Embodiment three please refer to Figure 1-8 , the horizontal adjustment device 4 includes a horizontal handle 20, a mounting plate 21, a horizontal screw rod 22, a buffer 23, a fixed shaft 24 and a support shaft 25, one end of the support shaft 25 is fixedly connected with the fixed plate 13, and the support The other end of the shaft 25 runs through the mounting plate 21, and the supporting shaft 25 is slidably connected with the mounting plate 21. The middle part of the mounting plate 21 is provided with a threaded hole, and the mounting plate 21 is movably connected with the horizontal screw rod 22 through the threaded hole. One end of the horizontal screw rod 22 is fixed to the horizontal handle 20, the other end of the horizontal screw rod 22 is fixed to the fixed shaft 24 through the buffer member 23, and the end of the fixed shaft 24 away from the buffer member 23 rotates through the bearing and the fixed plate 13 The two ends of the installation plate 21 are sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com