Finish carving machine

A technology of engraving machines and machine bases, applied in the field of engraving machines, can solve the problems of low machining efficiency of engraving machines, achieve the effects of reducing labor management costs and use costs, improving processing efficiency, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

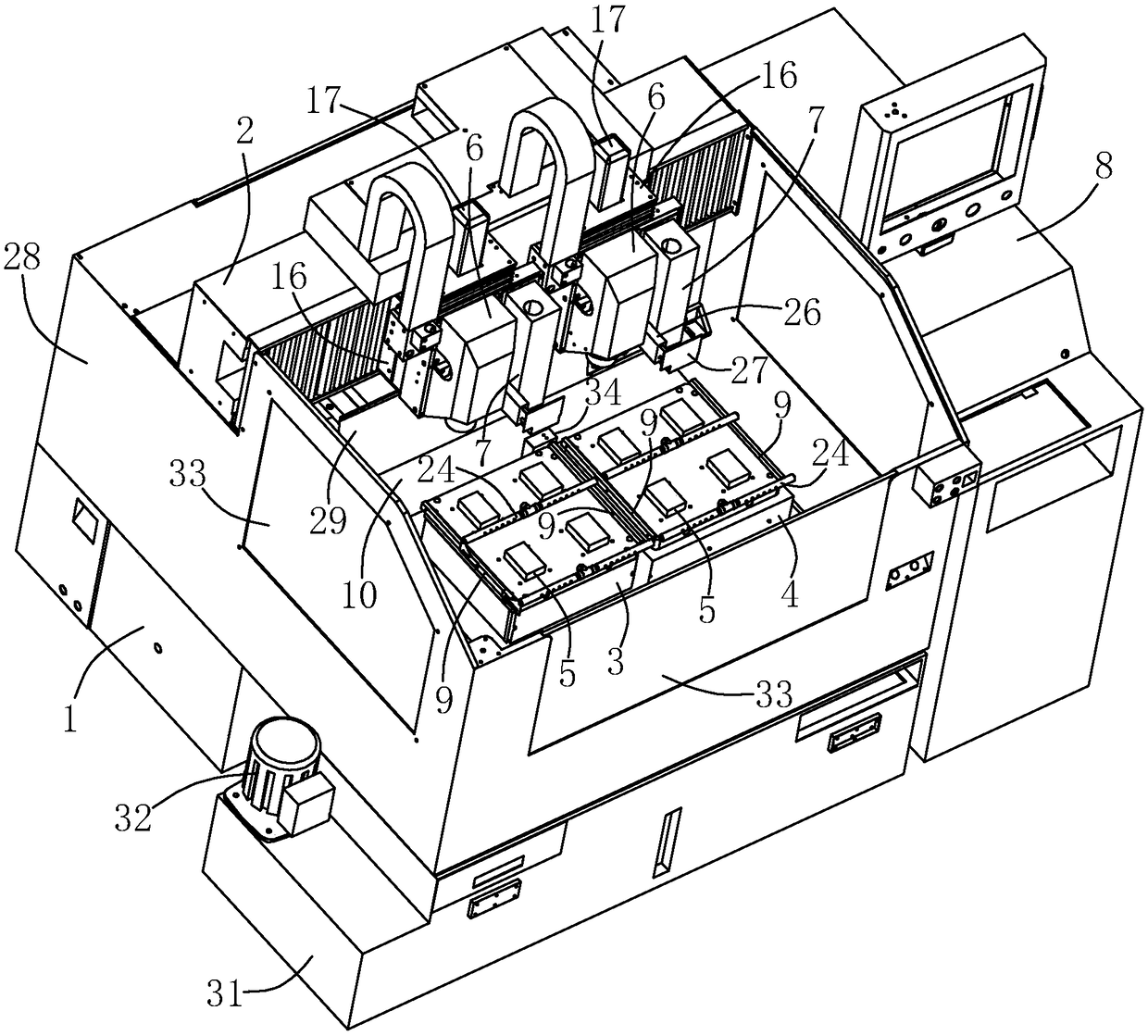

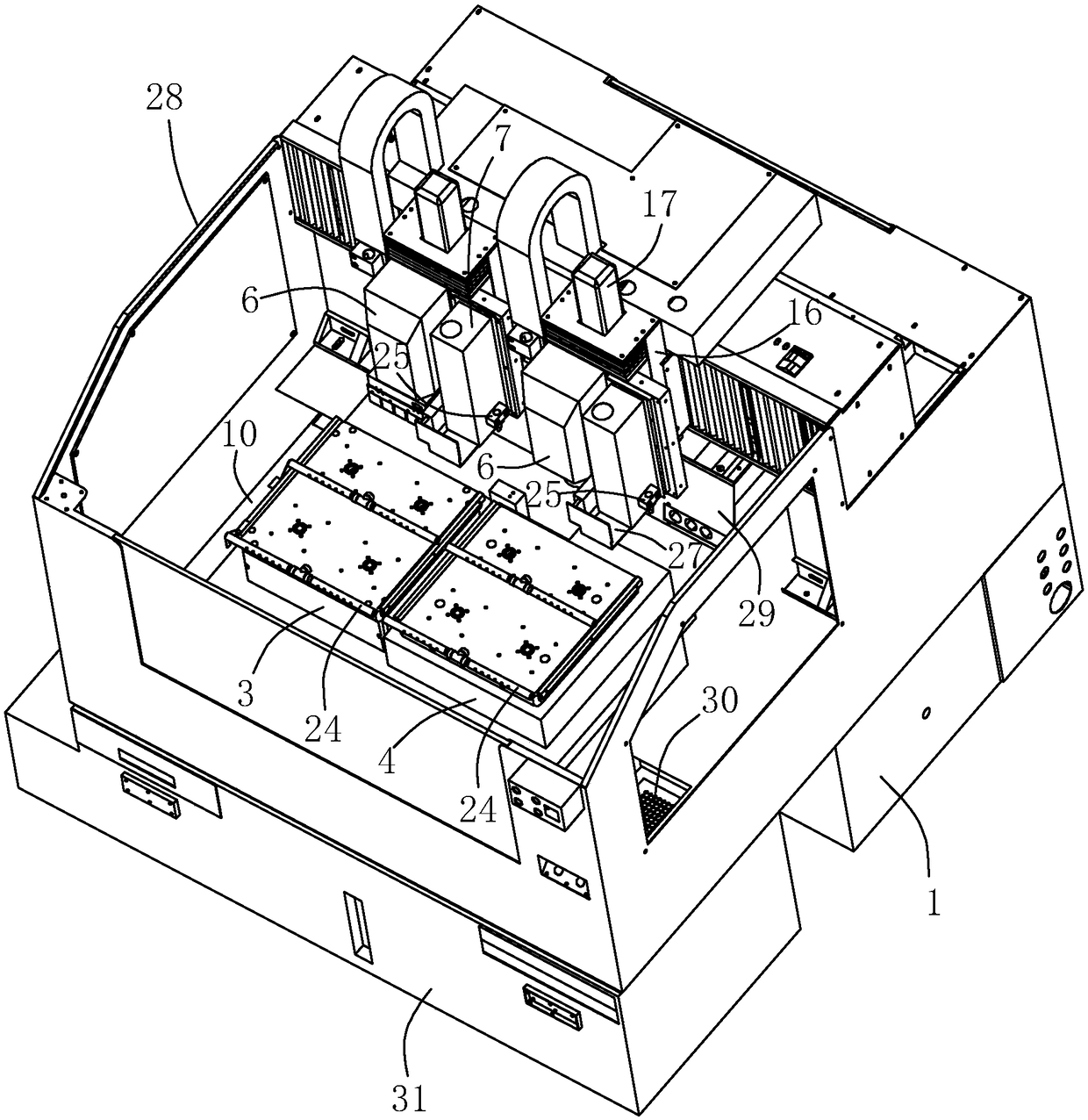

[0039] Embodiment one: a kind of engraving machine, such as figure 1 As shown, it includes: machine base 1, which is provided with a group of gantry structures 2 for switching between processing stations and non-processing stations. Both machine base 1 and gantry structure 2 are made of marble. In the embodiment, the gantry structure 2 can be in multiple groups; a reference platform 3 and a correction platform 4 are arranged on the machine base 1. In other embodiments, the number of the correction platform 4 can be multiple, and the reference platform 3 and the correction platform 4 Both are used to carry the same workpiece 5 with the same processing requirements; the two groups of activities are set on the gantry structure 2, which correspond to the reference table 3 and the correction table 4 on the processing station, and the linkage type respectively corresponds to the reference table 3 and the machine head 6 for processing the workpiece 5 carried on the correction table 4...

Embodiment 2

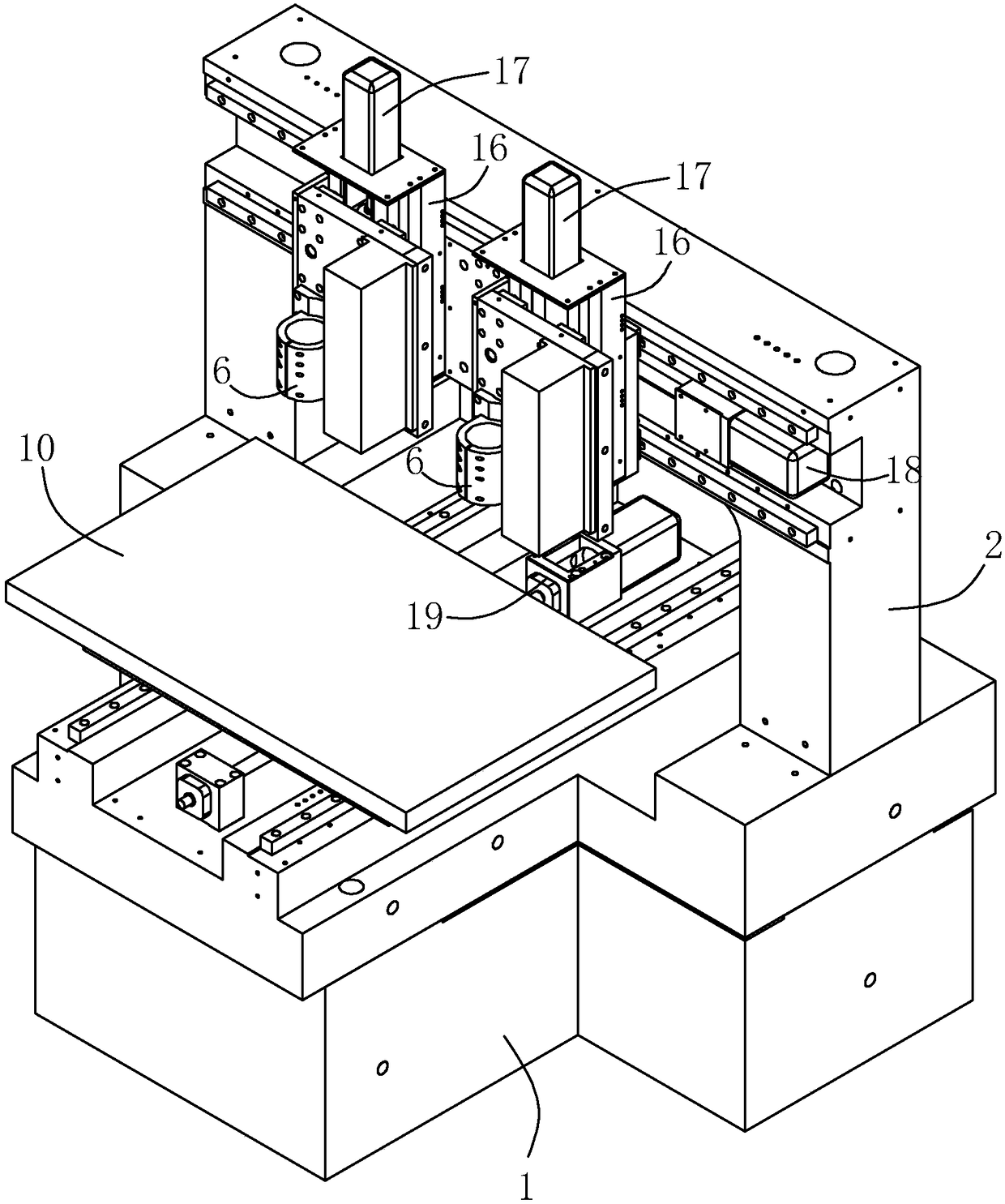

[0052] Embodiment 2: a kind of engraving machine, the difference from other embodiments is that in combination with figure 2 As shown, the installation platform 10 is fixedly installed on the machine base 1, and the gantry structure 2 is longitudinally slidably assembled on the machine base 1 and driven by the seventh driving member 20 ( figure 1 The seventh driving member 20 is not specifically shown), and the seventh driving member 20 is specifically a motor-driven ball screw structure and is also controlled by the control center 8 . This structure can also realize the longitudinal movement of the machine head 6 relative to the mounting table 10 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap