Container-type hydrogen refueling station

A containerized and containerized technology, which is applied in the field of hydrogen refueling stations, can solve the problems of long construction period of hydrogen refueling stations, and achieve the effect of shortening the construction period and avoiding negative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of a container-type hydrogen refueling station provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

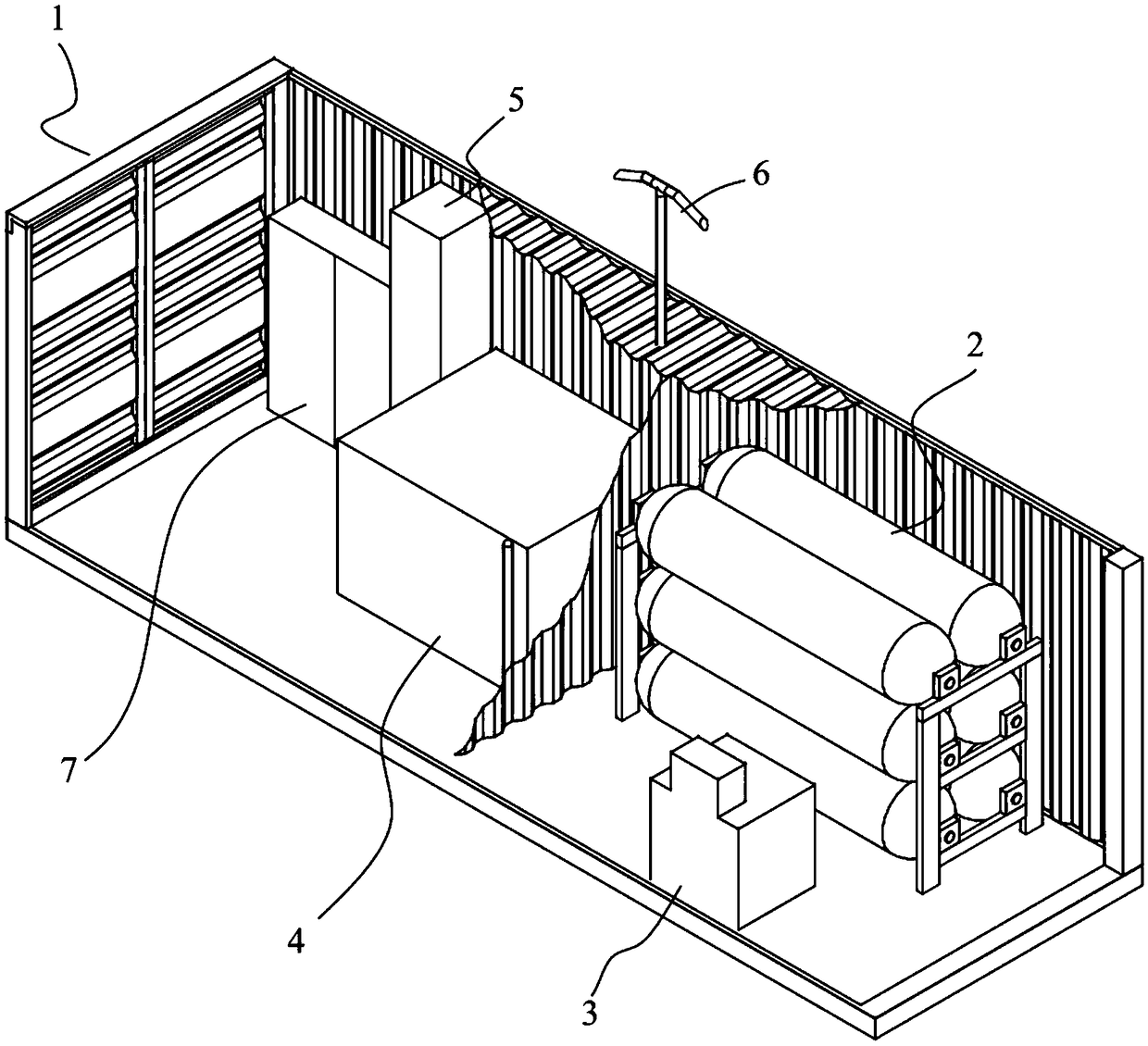

[0016] The figure includes the following components: 1-container box, 2-high-pressure hydrogen storage tank, 3-hydrogen compressor, 4-heat exchange equipment, 5-power supply cabinet, 6-hydrogen gas release device and 7-PLC electrical cabinet.

[0017] Such as figure 1 As shown, a container-type hydrogen refueling station includes a container body, which is provided with at least one high-pressure hydrogen gas storage tank, a hydrogen compressor, heat exchange equipment, a power cabinet and a PLC electrical cabinet, and the power cabinet integrates There is a power supply device, and programmable control equipment is integrated in the PLC electrical cabinet; the hydrogen compressor is connected to the high-pressure hydrogen gas storage tank, and the low-pressure hydrogen input from ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap