A kind of preparation technology of 2-aminonaphthalenesulfonic acid mixture

A technology for preparing aminonaphthalenesulfonic acid and its preparation technology is applied in the field of preparation technology of 2-aminonaphthalenesulfonic acid mixture, which can solve the problems of low utilization rate of 2-naphthol, great difficulty in environmental protection treatment, large amount of waste acid, etc., and achieve improvement Utilization rate, less waste acid, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

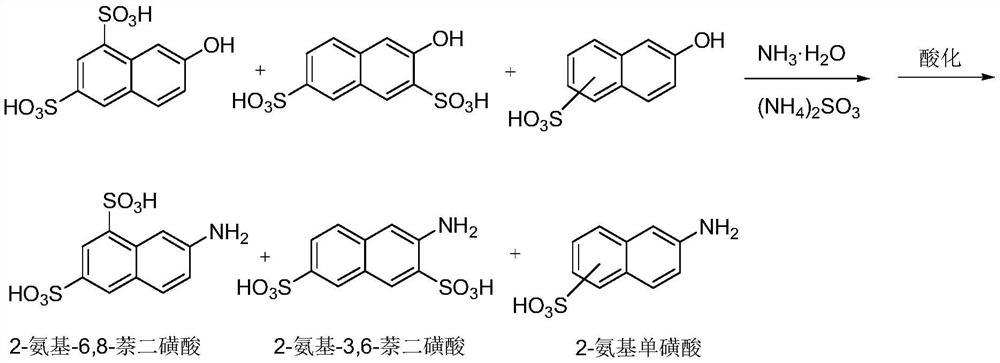

[0057] In a stirring four-neck flask, add 110g of 98% sulfuric acid, add 100g of 2-naphthol under stirring and cooling, stir for half an hour, then add 190g of 105% sulfuric acid and react at about 80°C for 12 hours. After the reaction, Put the sulfonated compound into 500g of 22% ammonia water, add ammonia water to adjust the ammonia value to about 4.5%, add 60g of ammonium sulfite, react at a temperature of 180°C for 16 hours, cool down, deammoniate, neutralize with 50% sulfuric acid, remove sulfur dioxide, cool down, Suction filtration and drying to obtain 268g of the product, which is a mixture of 2-aminonaphthalenesulfonic acid, with an amino value of 72.3% (calculated as 2-amino-6,8-naphthalenedisulfonic acid)

Embodiment 2

[0059] Add 1000 parts of 100% sulfuric acid to the sulfonation tank, add 1000 parts of 2-naphthol under stirring and cooling, stir for half an hour after adding, then add 1650 parts of 105% sulfuric acid, react at about 80 ° C for 10 hours, and sulfonate Put in 25% ammonia water, finally adjust and neutralize the liquid ammonia value to about 4.5%, add 600 parts of ammonium sulfite, react at 170°C for 18 hours, cool down, deammoniate, neutralize with 50% sulfuric acid, remove sulfur dioxide, cool down, and filter with suction , oven dry, obtain 2968 parts of products, be 2-amino naphthalene sulfonic acid mixture, amino value 68.3%. (calculated as 2-amino-6,8-naphthalene disulfonic acid)

Embodiment 3

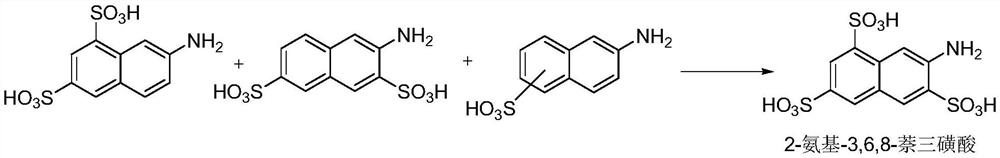

[0061] Take 1300 parts of the dried 2-aminonaphthalenesulfonic acid mixture and sulfonate it in 2650 parts of 65% oleum at a temperature of 135-140°C for 12 hours. Dilute the sulfonated solution in 1800 parts of water to adjust the reaction solution The concentration of sulfuric acid is 38-40%. After cooling down, filter to obtain 1426 parts of the product with a content of 72.6%. Based on 2-naphthol, the yield of 2-amino-3,6,8-naphthalenetrisulfonic acid is 88.94%, and the chromatographic purity of the product is 99.58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com