Cross-linked multilayer composition for intermediate connection of tubular busbar and shielding cylinder prepared therefrom

A technology of cross-linked composition and tubular busbar, which is applied to the installation of busbars, tubular articles, and fully enclosed busbar devices, etc., can solve the problems of product quality problems, increased installation and maintenance costs of enterprises, hidden dangers of power transmission safety, etc. , to achieve excellent electrical performance and chemical stability, avoid frequent repair and maintenance costs, production operations and processes are simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] As an embodiment of the present invention, the conductive functional filler is selected from one or a mixture of carbon black, carbon nanotubes, graphite, and graphene.

[0056] In the present invention, the conductive functional filler is modified.

[0057] In the present invention, the preparation method of the modified conductive functional filler is as follows:

[0058] 1. Disperse 1 part of conductive functional filler in 5 parts of anhydrous N,N-dimethylformamide, add 3 parts of ethylenediamine, 1.9 parts of dicyclohexylcarbodiimide and 1.5 parts of 4-dimethylamino After pyridine, stirred at 50°C for 8 hours, filtered, washed, and dried in vacuum at 40°C for 12 hours to obtain compound 1;

[0059] 2. Disperse the compound 1 obtained in step 1 in 5 parts of N-methyl-2-pyrrolidone, then add 3 parts of dimethylaminopyridine, 2 parts of pyridine, 1.5 parts of triphenyl phosphite, 0.01 part of LiCl, 2 Parts of 3,5-diaminobenzoic acid, 1.8 parts of trimesic acid, 1.6 ...

Embodiment approach 1

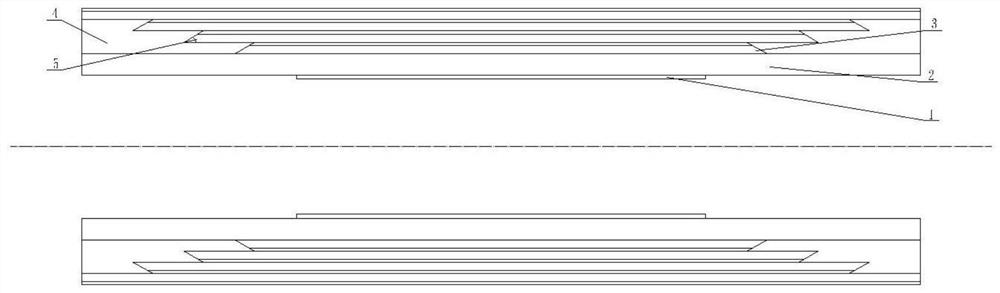

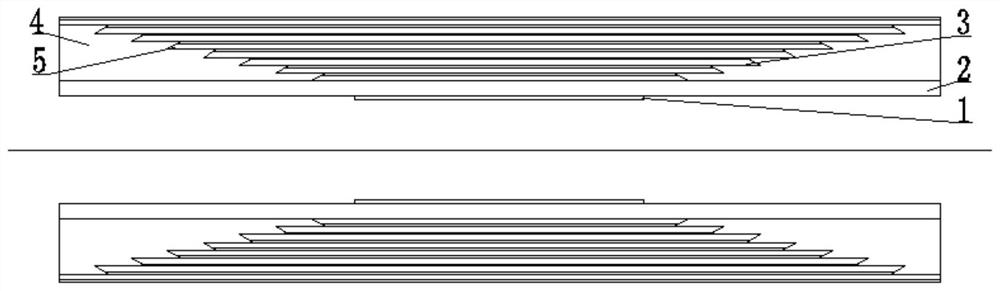

[0154] Embodiment 1. This embodiment provides a cross-linked multilayer composition for the intermediate connection of tubular busbars. The multilayer composition includes three layers, which are the inner shielding layer, the middle crosslinked insulating layer and the outer multilayer from the inside to the outside. Double-wall co-extruded heat-shrinkable tubing insulation / shielding;

[0155] Wherein, the insulation / shielding layer of the outer multi-layer double-wall co-extruded heat-shrinkable sleeve is superimposed by a double-layer structure type co-extruded heat-shrinkable sleeve;

[0156] The double-layer structure co-extruded heat-shrinkable sleeve is composed of an inner insulating layer and an outer shielding layer.

Embodiment approach 2

[0157] Embodiment 2. The cross-linked multilayer composition for the intermediate connection of tubular busbars described in Embodiment 1, in parts by weight, the raw materials for the preparation of the inner shielding layer include:

[0158] 70-90 parts of polyamide hot melt adhesive, 10-30 parts of thermoplastic elastomer, 10-50 parts of conductive functional filler, 1-3 parts of antioxidant and 10-20 parts of lubricant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com