High-valued treatment method for stainless steel pickling waste water

A technology of pickling wastewater and treatment method, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the problems of no recovery of valuable metals, no further recovery of calcium ions, etc., and achieves easy operation and is conducive to industrial production. , to achieve the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

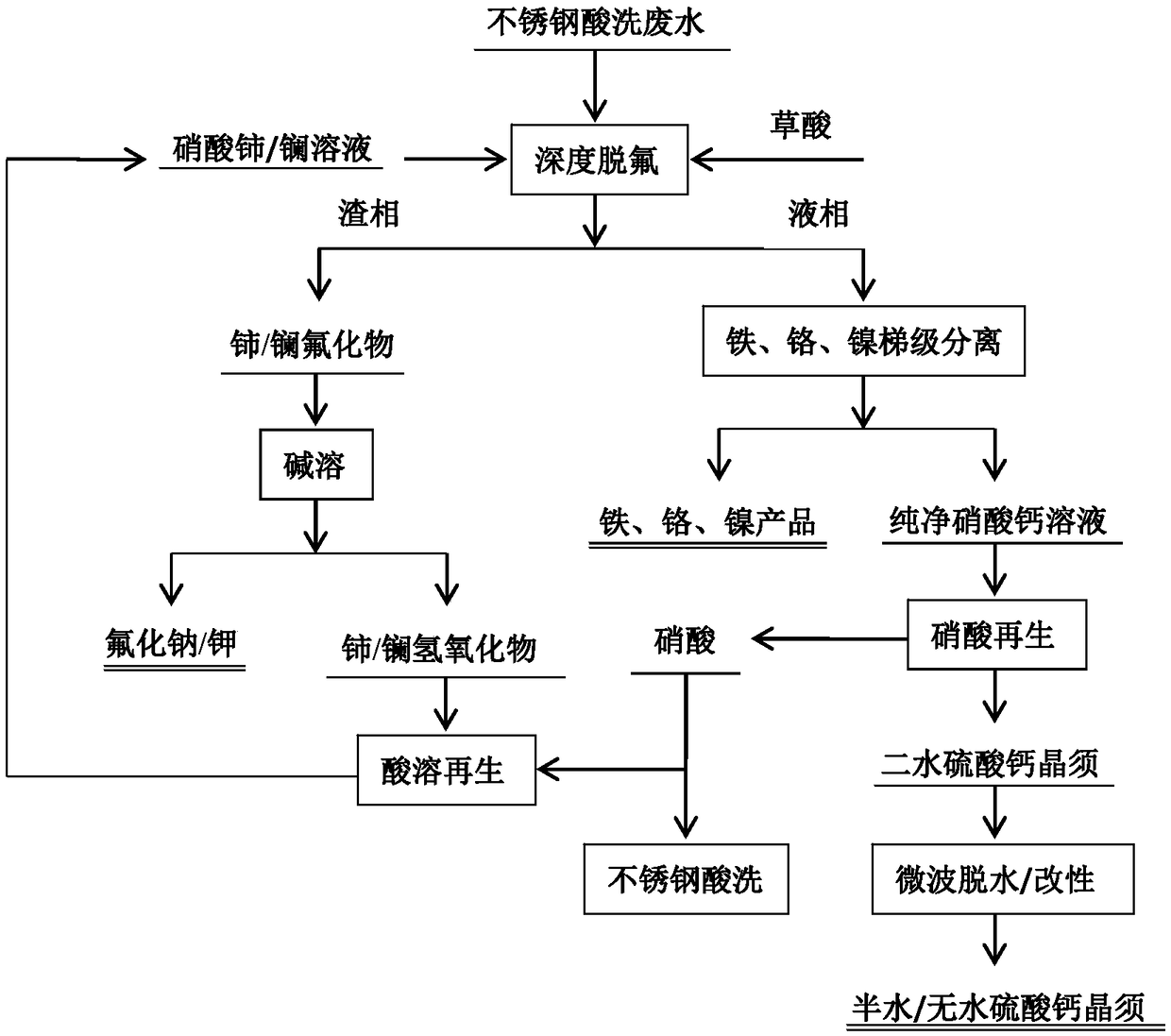

Image

Examples

Embodiment 1

[0045] A high-value treatment method for stainless steel pickling wastewater, comprising:

[0046] Take 500ml of stainless steel pickling wastewater, which contains 50g / L of NO 3 - , 40g / L of F - , 37g / L of Fe 3+ , 8g / L Cr 3 + , 5g / L Ni 2+, 80g / L residual acid; add 87.6ml molar concentration of 4mol / L cerium nitrate, lanthanum mixed solution (1:10 mix) and 7ml molar concentration of 2mol / L oxalic acid solution for deep defluorination, defluorination reaction 0.5 h, liquid phase and slag phase are obtained after defluorination is completed, and the slag phase is a mixture of cerium fluoride and lanthanum fluoride; the mixture of cerium fluoride and lanthanum fluoride is alkali-dissolved with 200g / L potassium hydroxide solution to obtain fluoride The mixture of potassium, cerium hydroxide and lanthanum hydroxide; the mixture of cerium hydroxide and lanthanum hydroxide is acid-dissolved and regenerated with the nitric acid produced in the 0.8mol / L nitric acid regeneration p...

Embodiment 2

[0048] A high-value treatment method for stainless steel pickling wastewater, comprising:

[0049] Take 500ml of stainless steel pickling wastewater, which contains 150g / L of NO 3 - , 20g / L of F - , 36g / L of Fe 3+ , 10g / L Cr 3+ , 3.5g / L Ni 2+ , 30g / L residual acid; adding 43.8ml molar concentration of 4mol / L cerium nitrate, lanthanum mixed solution (1:6 mixing) and 7.5ml molar concentration of 1.5mol / L oxalic acid solution for deep defluorination, defluorination After reacting for 3 hours, a liquid phase and a slag phase are obtained after the defluorination is completed, and the slag phase is a mixture of cerium fluoride and lanthanum fluoride; The mixture of sodium chloride, cerium hydroxide and lanthanum hydroxide; the mixture of cerium hydroxide and lanthanum hydroxide is regenerated with nitric acid produced in the 2.4mol / L nitric acid regeneration process, and all the acid-dissolved regeneration products are returned to the deep defluorination process; Add calcium ...

Embodiment 3

[0051] A high-value treatment method for stainless steel pickling wastewater, comprising:

[0052] Take 500ml of stainless steel pickling wastewater, which contains 100g / L of NO 3 - , 60g / L F - , 30g / L of Fe 3+ , 9g / L of Cr 3+ , 4.3g / L Ni 2+ , 40g / L residual acid; add 131.4ml molar concentration of 4mol / L cerium nitrate, lanthanum mixed solution (1:1 mixing) and 9ml molar concentration of 0.5mol / L oxalic acid solution for deep defluorination, defluorination reaction After 3.5h, the liquid phase and the slag phase are obtained after the defluorination is completed. The slag phase is a mixture of cerium fluoride and lanthanum fluoride; The mixture of potassium chloride, cerium hydroxide and lanthanum hydroxide; the mixture of cerium hydroxide and lanthanum hydroxide is regenerated with nitric acid produced in the 1.6mol / L nitric acid regeneration process, and all the acid-soluble regeneration products are returned to the deep defluorination process; Add calcium oxide to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap